A class of metal oxide materials with special microstructure, and preparation method thereof

A microstructure and oxide technology, applied in the field of materials, can solve the problems of high risk, difficult operation, inability to synthesize metal oxide materials, etc., and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

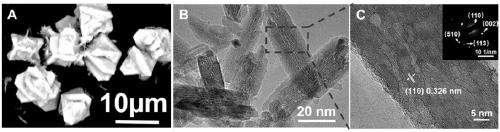

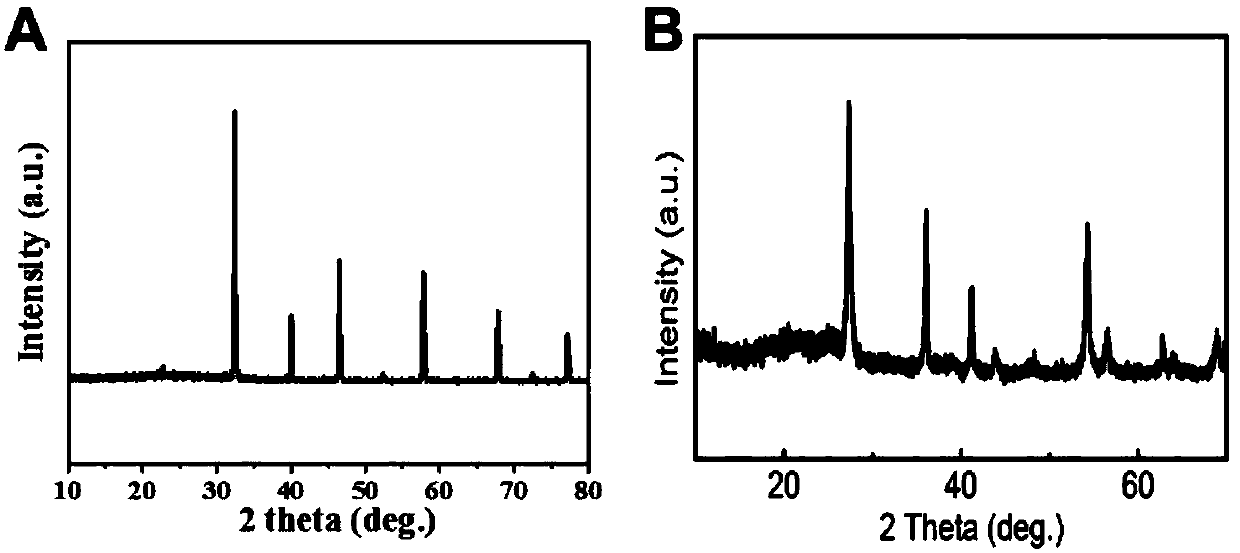

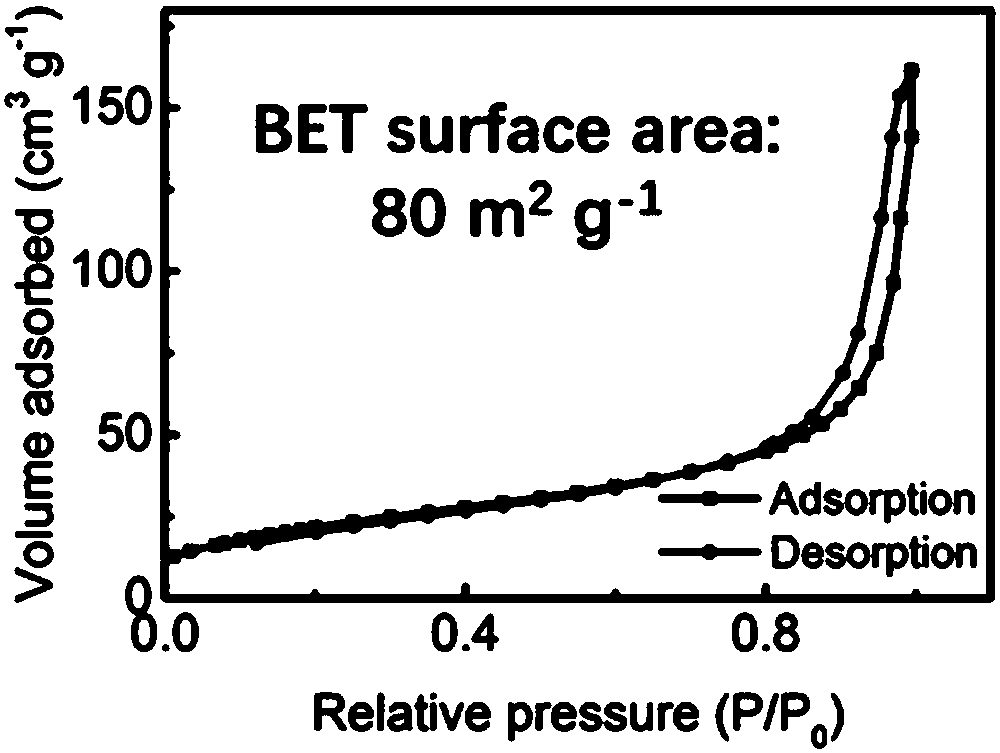

[0031] Weigh 0.5 g of ruthenium-doped strontium titanate SrRu synthesized by hydrothermal method 0.05 Ti 0.95 o 3 Put it into a 50mL high temperature and high pressure reactor, add 1molL -1 Hydrochloric acid aqueous solution, after stirring evenly, seal the reactor and put it in a constant temperature oven at 130°C to react for 10 days. During the reaction, the hydrochloric acid will etch out the strontium in the raw material and dissolve it into the aqueous solution. After opening at room temperature, the precipitate was separated by filtration, washed 3 times with deionized water, and then dried with a freeze dryer for 24 hours to obtain a brown product that is ruthenium-doped titanium dioxide Ru 0.05 Ti 0.95 o 2 .

[0032] Product ruthenium doped titania Ru 0.05 Ti 0.95 o 2 The TEM, XRD, nitrogen adsorption-desorption isotherms and the SEM and XRD of raw materials are attached Figure 1-3 shown.

Embodiment 2

[0034] Weigh 0.5 g of ruthenium-doped strontium titanate SrRu synthesized by hydrothermal method 0.05 Ti 0.95 o 3 Put it into a 50mL high temperature and high pressure reactor, add 1molL -1 Hydrochloric acid aqueous solution, after stirring evenly, seal the reactor and put it in a constant temperature oven at 130°C to react for 150 minutes. During the reaction, the hydrochloric acid will etch the strontium in the raw material and dissolve it into the aqueous solution. After opening at room temperature, the precipitate was separated by filtration, washed 3 times with deionized water, and then dried with a freeze dryer for 24 hours to obtain a brown product that is ruthenium-doped titanium dioxide Ru 0.05 Ti 0.95 o 2 .

[0035] Product ruthenium doped titania Ru 0.05 Ti 0.95 o 2 TEM, XRD, nitrogen adsorption-desorption isotherm and SEM and XRD of raw materials are attached Figure 1-3 shown. Implementation Example 3

Embodiment 3

[0036] Weigh 0.5 g of ruthenium-doped strontium titanate SrRu synthesized by hydrothermal method 0.05 Ti 0.95 o 3 Put it into a 50mL high temperature and high pressure reactor, add 1molL -1 Hydrochloric acid aqueous solution, after stirring evenly, seal the reactor and put it in a constant temperature oven at 60°C to react for 5 minutes. During the reaction, the hydrochloric acid will etch the strontium in the raw material and dissolve it into the aqueous solution. After opening at room temperature, the precipitate was separated by filtration, washed 3 times with deionized water, and then dried with a freeze dryer for 24 hours to obtain a brown product that is ruthenium-doped titanium dioxide Ru 0.05 Ti 0.95 o 2 .

[0037] Product ruthenium doped titania Ru 0.05 Ti 0.95 o 2 TEM, XRD, nitrogen adsorption-desorption isotherm and SEM and XRD of raw materials are attached Figure 1-3 shown. Implementation example 4:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com