Inner bag type oil tank

A fuel tank and bladder type technology, applied in the field of inner capsule fuel tanks, can solve the problems of oil pollution to the air, oil vapor overflow, fuel tank volatilization and explosion probability, etc., so as to save the oil vapor recovery device and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

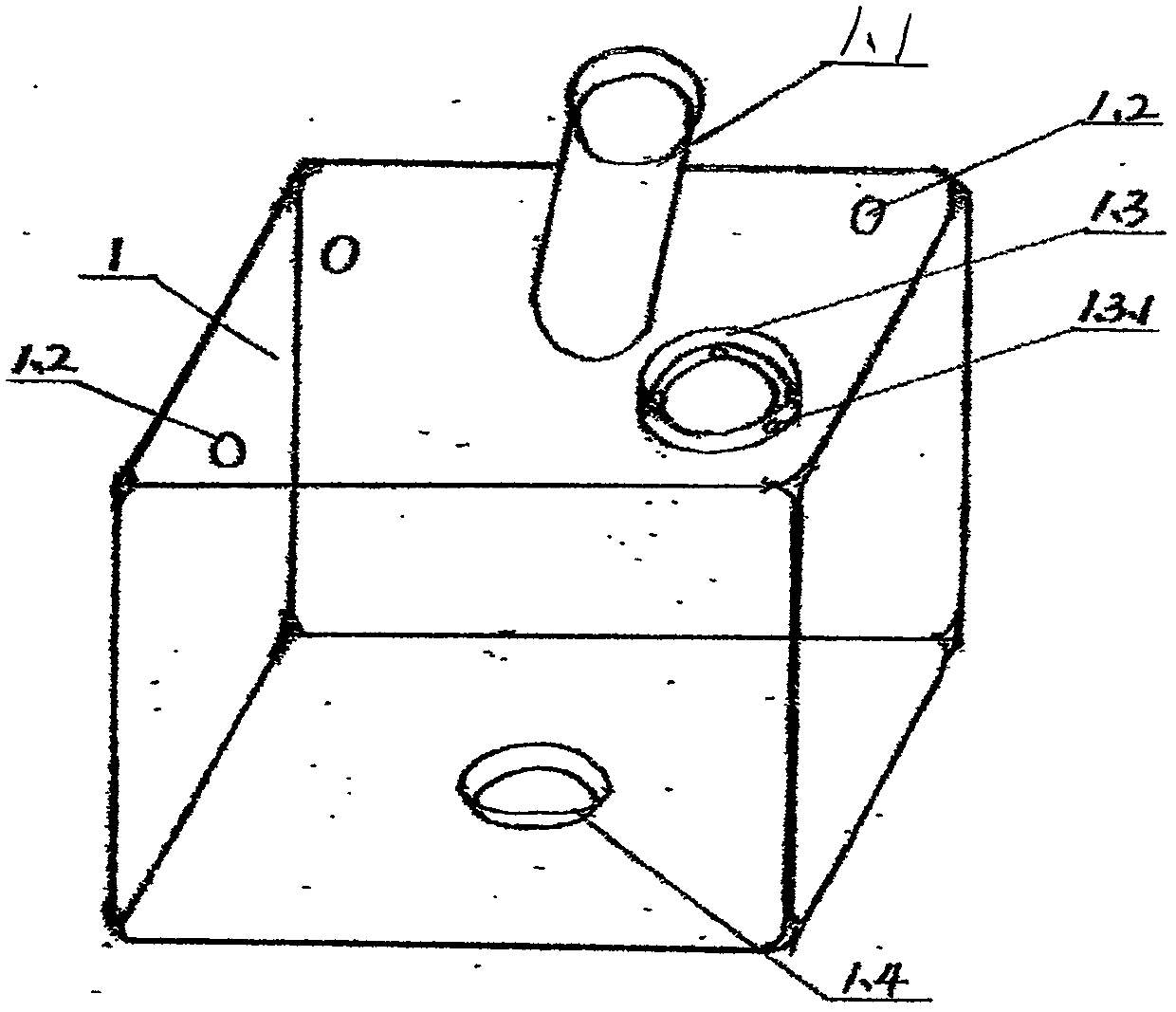

[0024] figure 1 As shown, the filling diameter 1.1, vent hole 1.2, and oil pump chamber assembly port 1.3 of the oil tank body 1 are on the top surface of the oil tank body 1, the lowest point 1.4 is set at the bottom, and three threaded holes 1.3.1 are arranged on the oil pump chamber assembly port 1.3 .

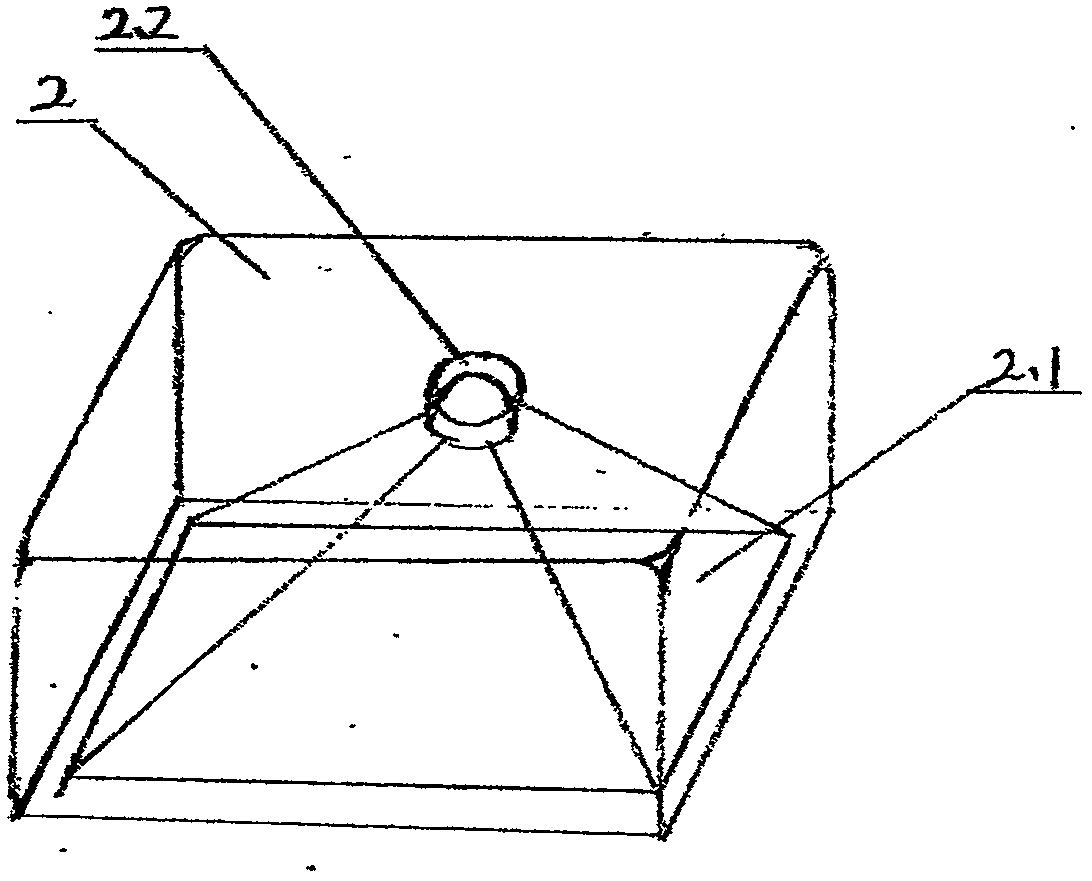

[0025] figure 2 Shown, telescoping body 2 bottoms are concave taper 2.1, are shaped on oil inlet pipe hole 2.2 at the cone top of taper, and the top in the top and oil tank body 1 follows shape.

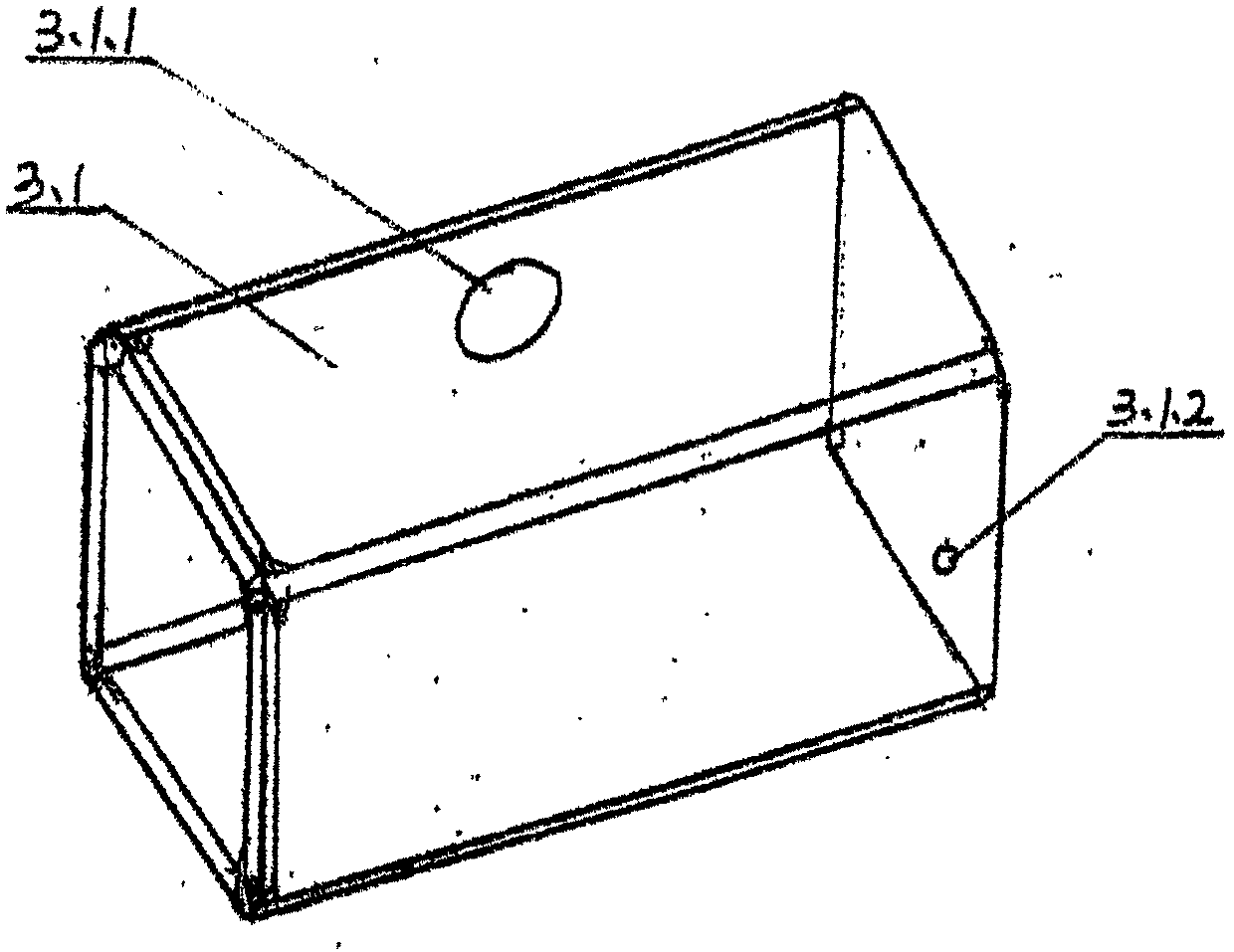

[0026] image 3 As shown, the capsule body 3.1 is heat-sealed by a composite membrane, and the upper part is provided with an oil inlet port 3.1.1, and the lower part of one end face is provided with an oil outlet hole 3.1.2. Schematic diagram of capsule structure

[0027] Figure 4 As shown, one end of the oil outlet pipe 3.3 is a wave section 3.3.1 and a magnetic part 3.3.3 is housed, and the middle part is shaped on a disc-shaped piece 3.3.2.

[0028] Figure 5 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com