Parallel rotor pump, liquid extraction method and engine dry oil sump lubrication system

A lubrication system, parallel technology, applied in the direction of engine lubrication, engine components, lubrication pumps, etc., can solve the problems of weakened lubrication effect, ablation of transmission parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

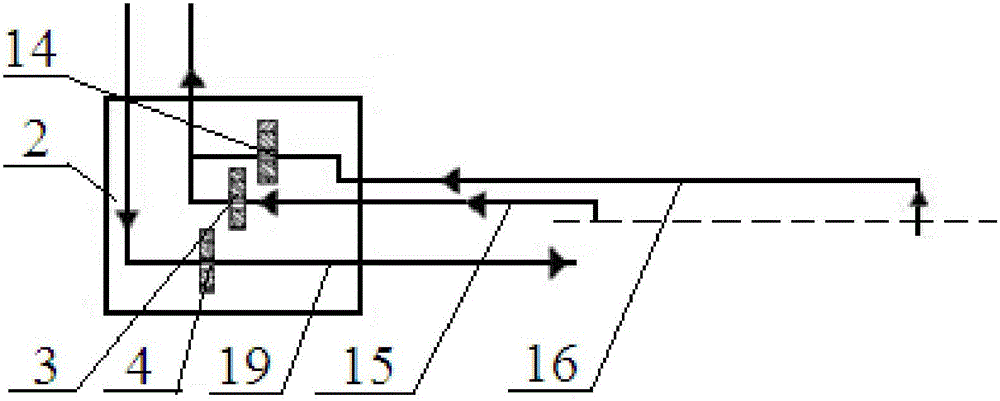

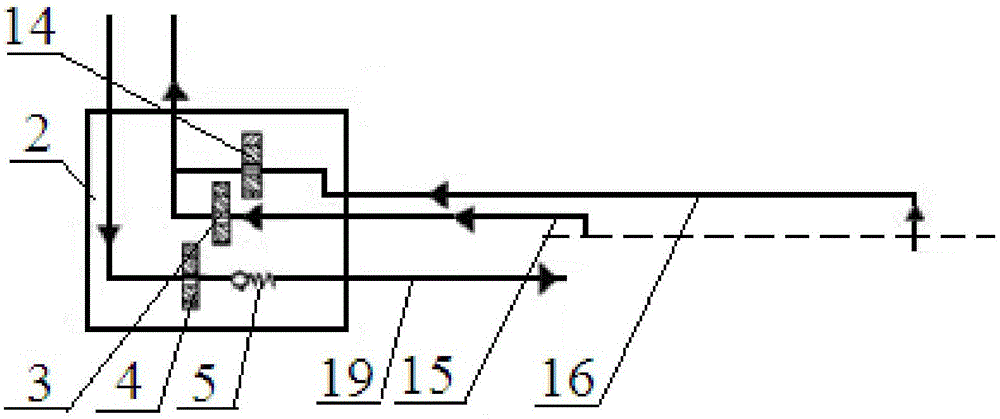

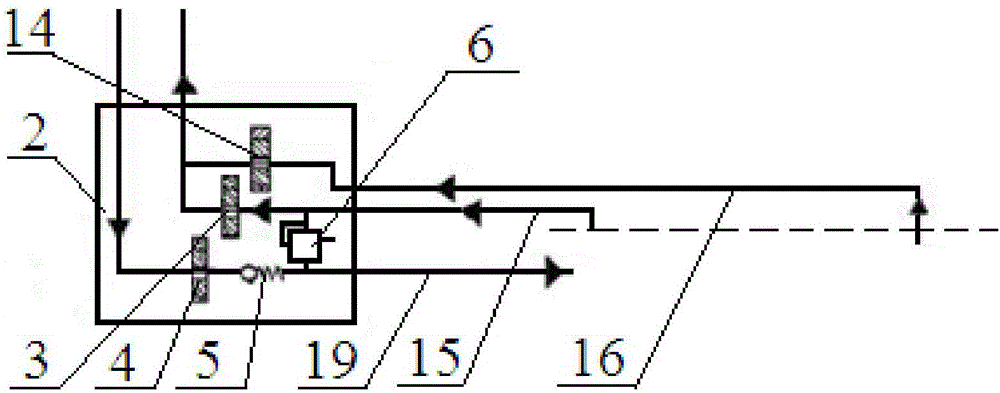

[0041] See attached figure 1 and 8 , the parallel rotor pump provided by the present invention includes:

[0042] The liquid supply rotor and at least two liquid extraction rotors, the liquid supply rotor is the primary rotor 4, the two liquid extraction rotors are the secondary rotor 3 and the tertiary rotor 14 respectively, and the primary rotor 4 runs in the same direction as the secondary rotor 3 and the tertiary rotor. The running direction of the first-stage rotor 14 is opposite; the second-stage rotor 3 is provided with a first liquid-taking passage 15, the third-stage rotor 14 is provided with a second liquid-taking passage 16, and the first-stage rotor is provided with a liquid supply passage 19. The output end of the liquid channel 15 and the output end of the second liquid-taking channel 16 are respectively communicated with the input end of the liquid-supply channel 19, so that the secondary rotor 3 and the tertiary rotor 14 form a parallel liquid-taking rotor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com