A composite heavy metal chelating agent for waste incineration fly ash and a preparation method thereof

A technology of waste incineration fly ash and heavy metal chelating agent, which is applied in the direction of protection device against harmful chemical agents, etc. The effect of low cost, simple preparation method and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

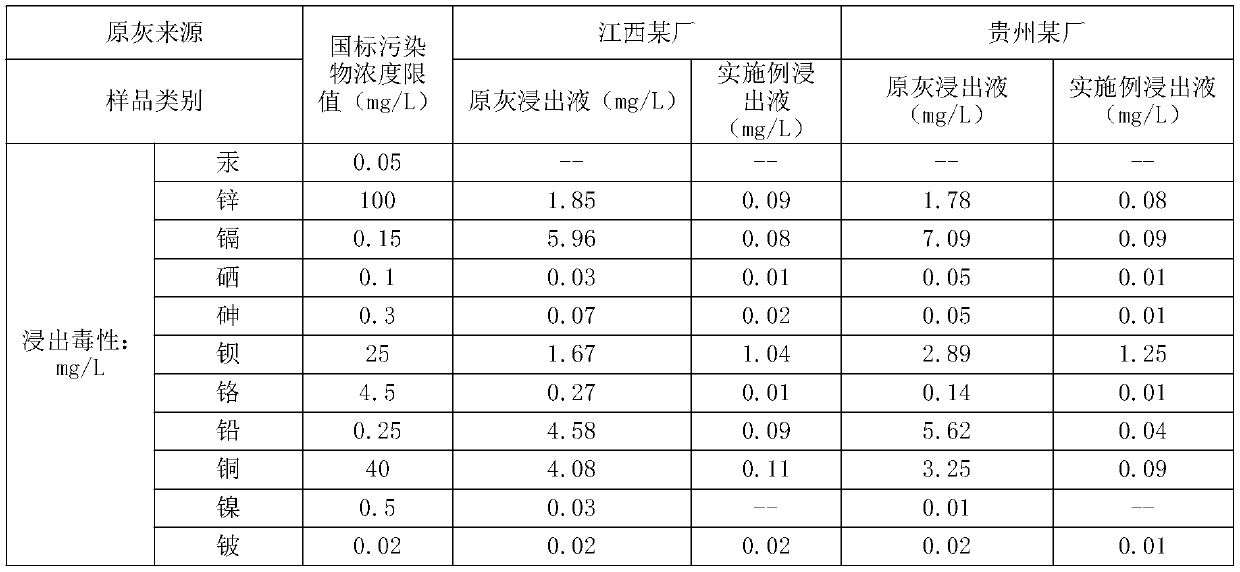

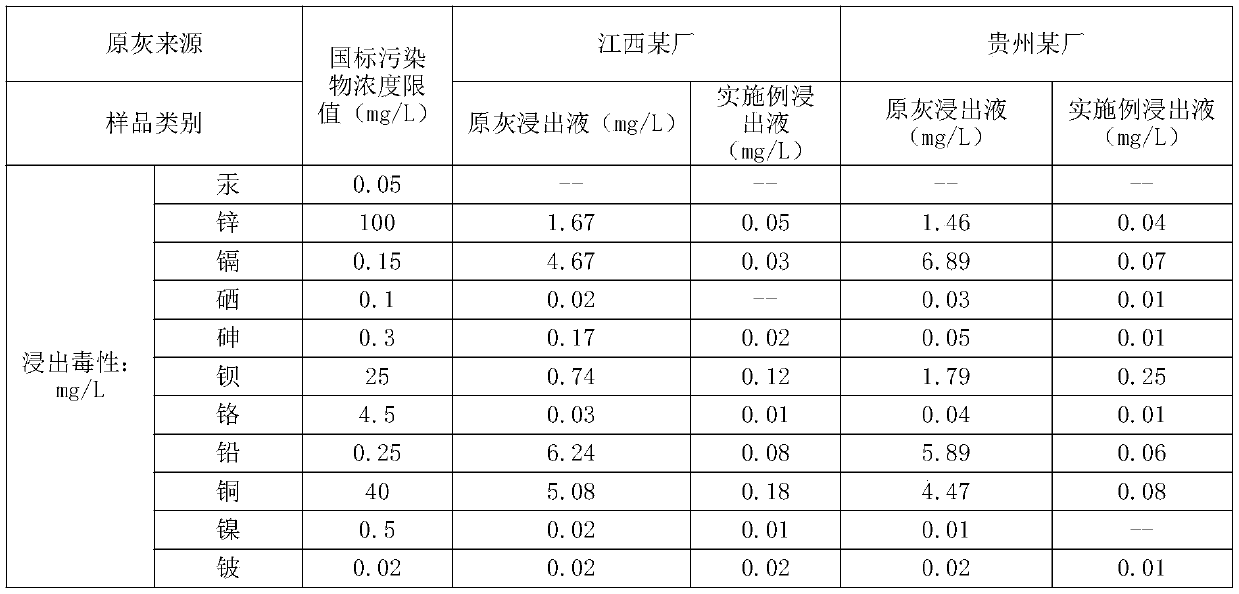

Examples

Embodiment 1

[0019] (1) In the mixing tank, inject 72kg of industrial water, add 15 kg of sodium butyl dithioxanthate and 5 kg of sodium dimethyl dithiocarbamate into the mixing tank successively; stir until completely dissolved while adding raw materials, to obtain a mixture.

[0020] (2) Add 5kg of trisodium hexametaphosphate, 2.5kg of sodium lignosulfonate, and 2.5kg of sodium silicate into the mixed liquid, stir for 1 hour at room temperature to form a mixed liquid, let it stand for 20 hours, and name it 1# heavy metal Chelating agent.

Embodiment 2

[0022] (1) In the mixing tank, inject 72kg of industrial water, add 12kg of sodium butyl dithioxanthate and 8kg of sodium dimethyl dithiocarbamate into the mixing tank successively; stir until completely dissolved while adding raw materials, to obtain a mixture.

[0023] (2) Add 5kg of trisodium hexametaphosphate, 2.5kg of sodium lignosulfonate, and 2.5kg of sodium silicate into the mixed liquid, stir for 1 hour at room temperature to form a mixed liquid, let it stand for 20 hours, and name it as 2# Metallic chelating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com