Spark plug with improved seal

A seal and spark plug technology, applied in the field of glass seals, can solve problems such as spark plug failure, insulator dielectric failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

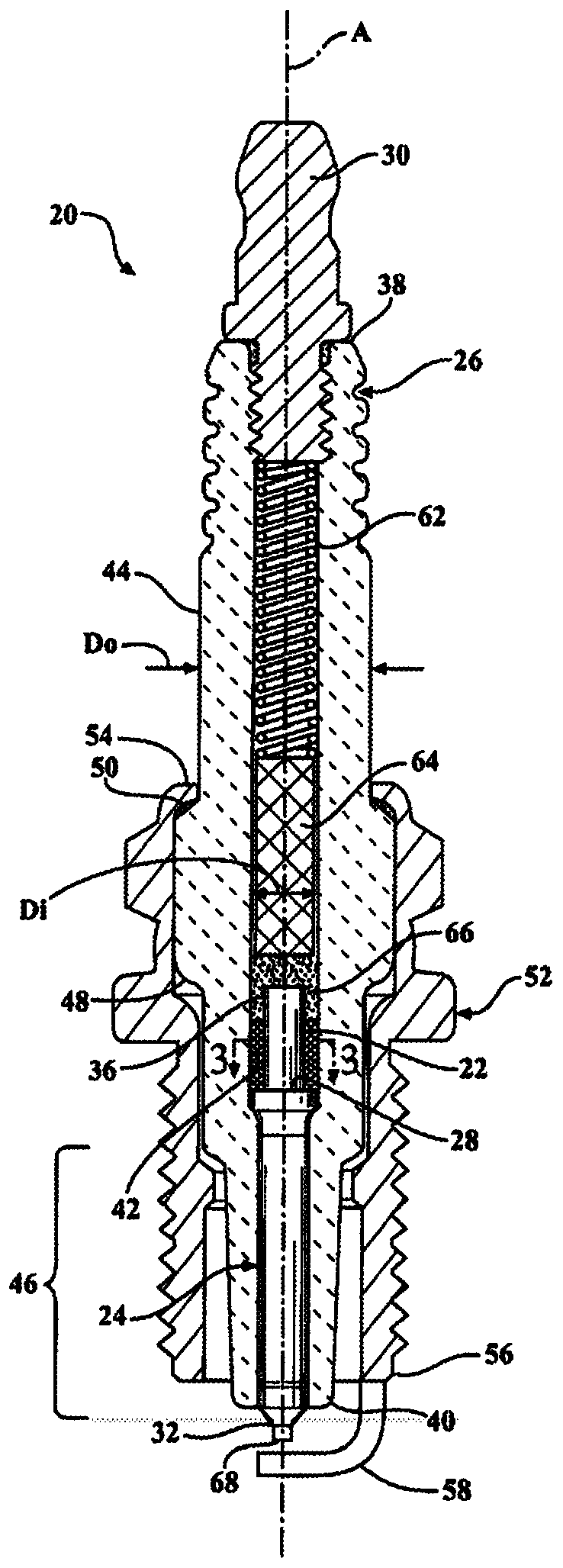

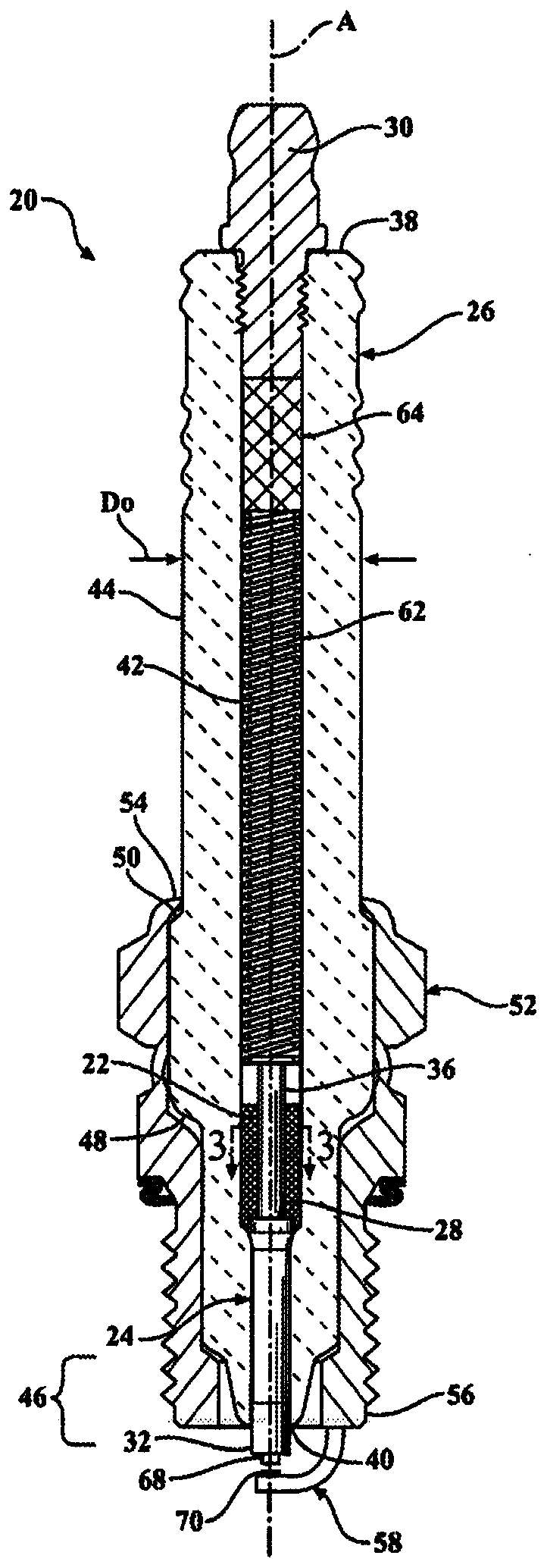

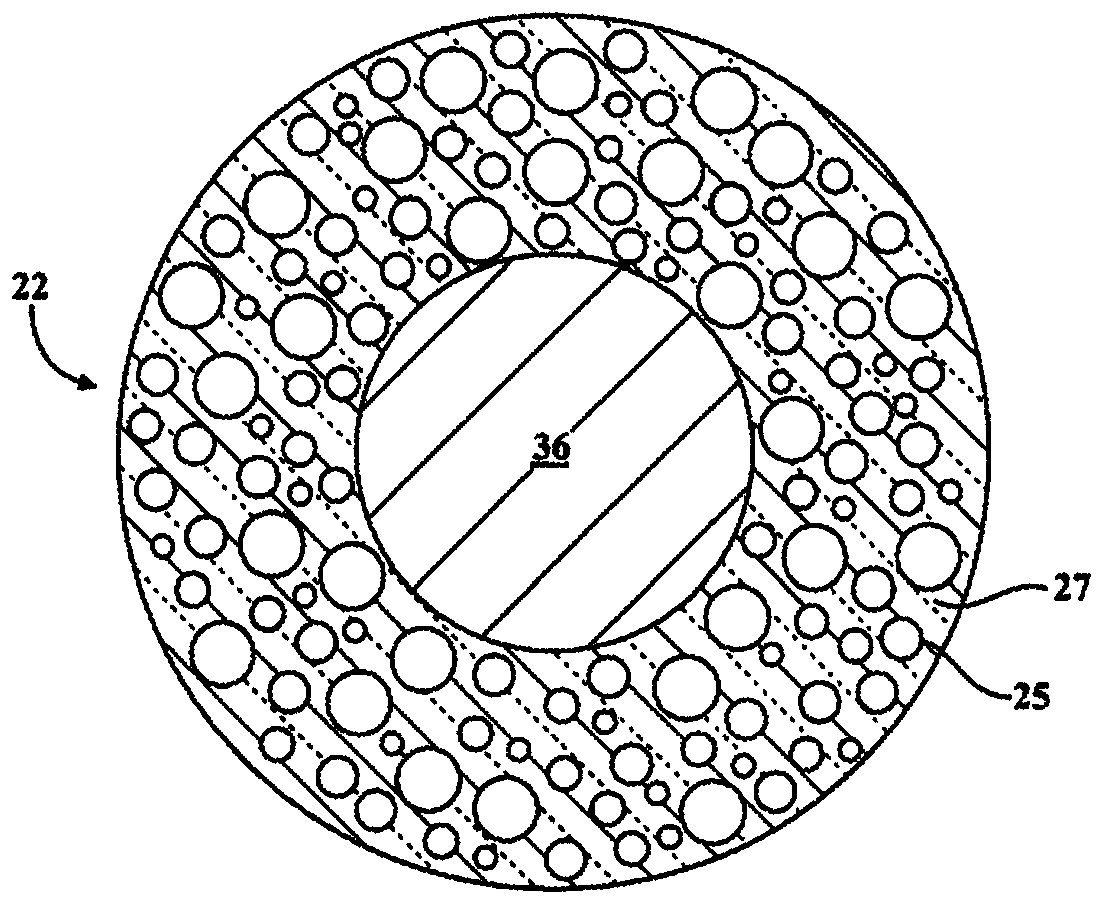

[0015] One aspect of the invention provides a spark plug 20 that includes a conductive glass seal 22 that provides a gas-tight bond between at least one conductive component (eg, center electrode 24) and an insulator 26, such as figure 1 and 2 shown. The composition of the glass seal 22 reduces the likelihood of dielectric breakdown and thus reduces dielectric penetration through the insulator 26 ( dielectric puncture).

[0016] Conductive glass seal 22 is formed from a material, typically a powder mixture, including conductive particles, at least one binder, an expansion agent, and glass frit. In an exemplary embodiment, glass seal 22 includes 10.0-50.0 weight percent (wt %), preferably 20.0 wt , conductive particles based on the total weight of glass seal 22 . The powder mixture used to form the glass seal 22 includes 10.0-50.0 wt % conductive particles based on the total weight of the powder used to form the glass seal 22 . The conductive particles may comprise a single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com