Anti-crystallization blanking coiling needle mechanism of ion wind static elimination of lithium battery electrical core

A technology of lithium battery and ion wind, which is applied in the field of anti-crystallization unloading needle mechanism, can solve problems such as explosion, overcharging, safety hazards, etc., to reduce the probability of explosion, protect the internal circulation of lithium ions and avoid external precipitation, good The effect of the stabilization circuit loop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

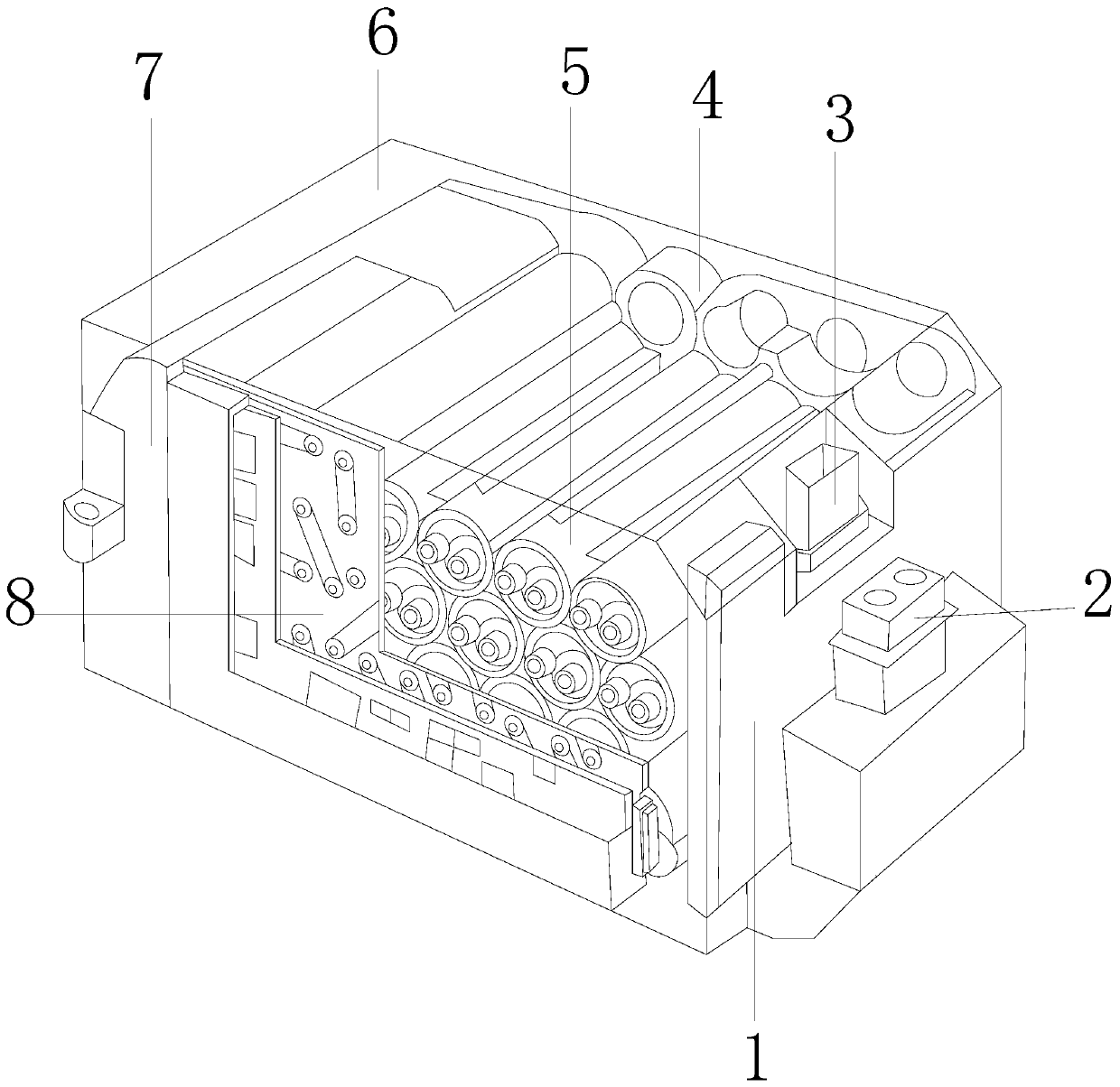

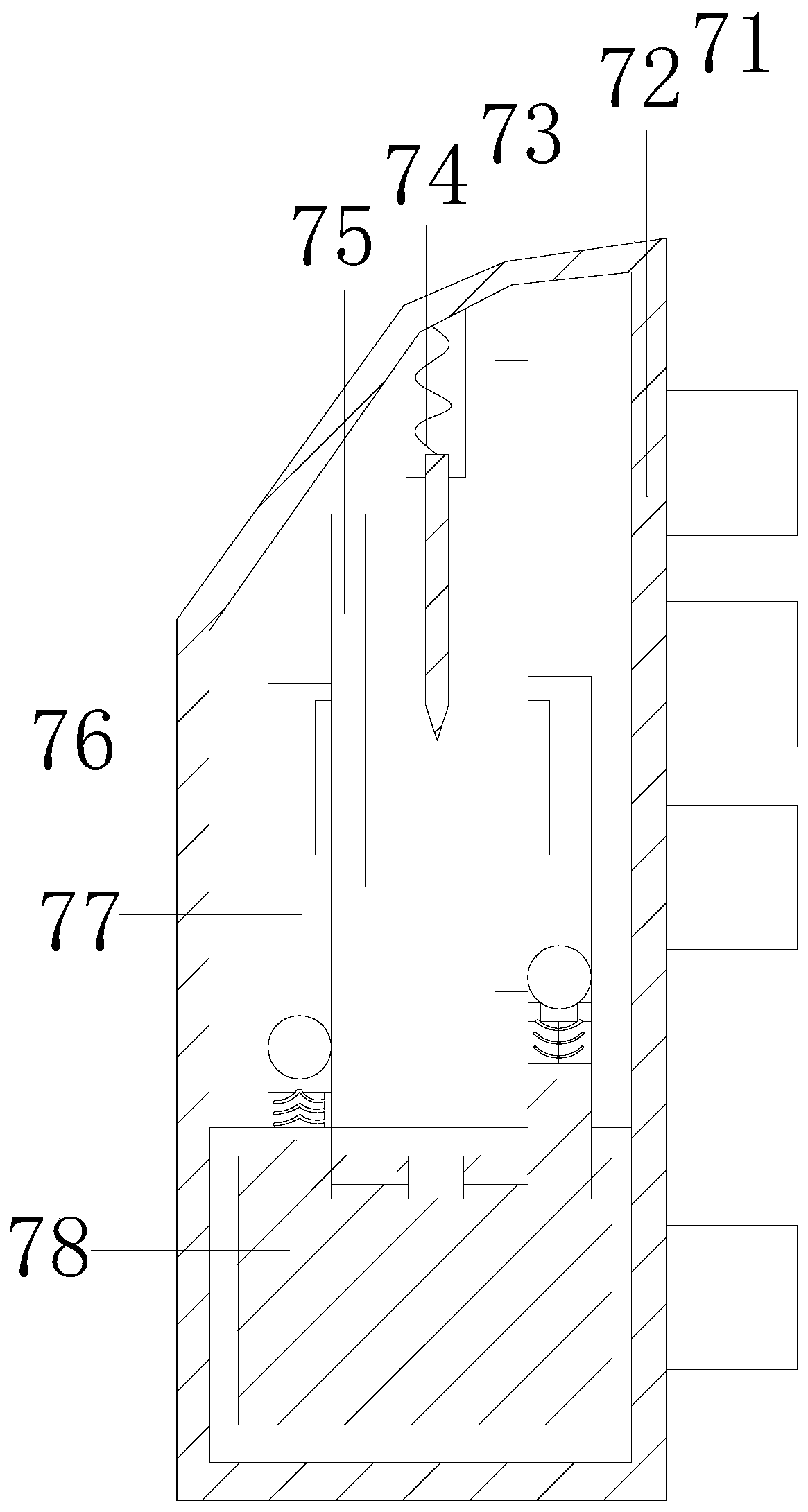

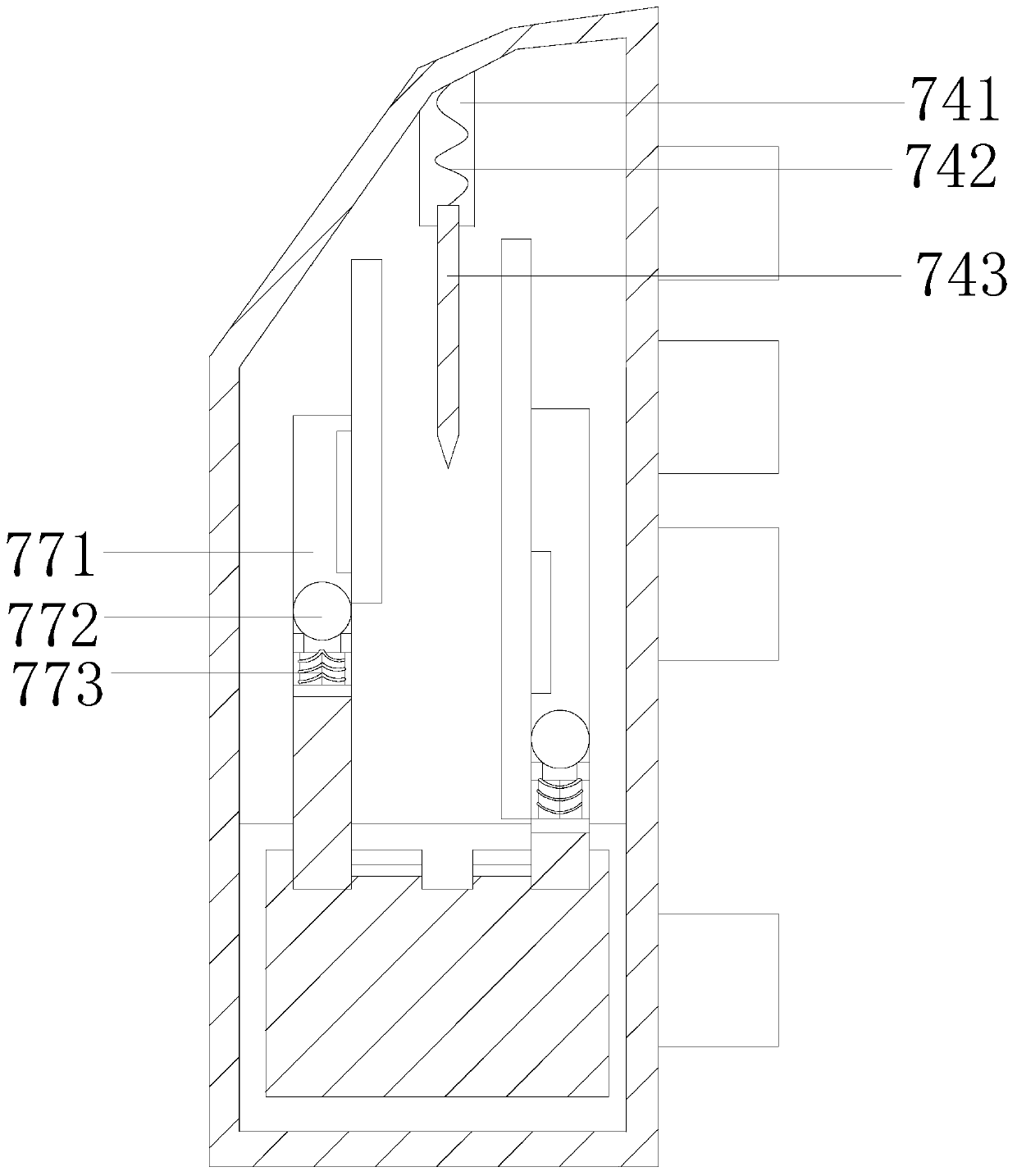

[0031] see Figure 1-Figure 7 , the present invention provides an anti-crystallization needle rolling mechanism for lithium battery cell ion wind destaticization, its structure includes: spacer anti-collision plate 1, double needle slot seat 2, parallel port 3, battery buckle seat 4 , lithium battery tube 5, shell cover 6, pole plate liquid column mechanism 7, circuit board 8, described pole plate liquid column mechanism 7 is inserted and embedded in the left side of circuit board 8, the tin backing plate of described circuit board 8 and lithium The column end of the battery tube 5 is electrically connected, the plate liquid column mechanism 7 and the spacer anti-collision plate 1 are respectively attached to the left and right sides of the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com