Silicon monoxide-based carbon negative electrode material, negative electrode plate, preparation method thereof and lithium ion battery

A technology of silicon oxide-based carbon and lithium-ion batteries, which is applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of poor coating effect, low first effect of materials, unsatisfactory cycle stability, etc., and achieve cost reduction. Low, improve the first effect, enhance the effect of thermal stability and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

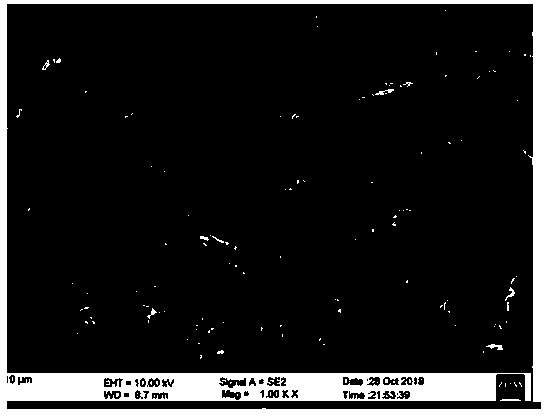

Image

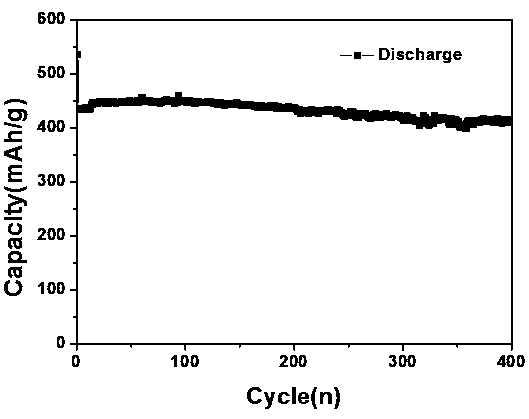

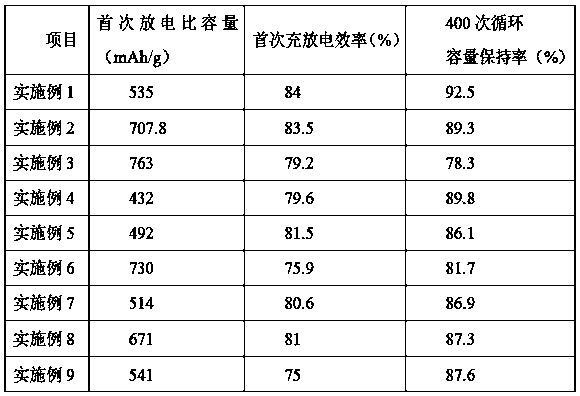

Examples

Embodiment 1

[0040] A method for preparing a siloxa-based carbon negative electrode material includes the following steps:

[0041] (1) Silica pretreatment: The silica powder with an average particle size of 5-20μm is calcined at 1000°C for 10 hours under argon protection, and the heating rate is 3°C / min. When the furnace is cooled to room temperature, put the calcined silicon oxide into a ball mill (zirconia is the ball milling medium) for dry ball milling. The ball mill tank is filled with argon gas, the ball-to-battery ratio is 5:1, and the speed of the ball mill is 800 rpm, ball milling time is 10 hours. Then, the ball-milled silicon oxide was dispersed in a 1M sodium hydroxide solution to form a slurry, the solid content was controlled at 7wt%, and the slurry was etched on a magnetic stirrer for 3h. The slurry was washed and vacuumed at 70°C. Dry treatment for 4 hours to obtain pretreated silica;

[0042] (2) Preparation of silicon oxide-based carbon precursor: under the protection of ar...

Embodiment 2

[0048] A method for preparing a siloxa-based carbon negative electrode material includes the following steps:

[0049] (1) Silica pretreatment: The silica powder with an average particle size of 5-20μm is calcined at 800°C for 15 hours under the protection of neon gas at a heating rate of 2°C / min. When the furnace is cooled to room temperature, put the calcined silicon oxide into a ball mill (zirconia is the ball milling medium) for dry ball milling. The ball mill tank is filled with argon gas, the ball to material ratio is 3:1, and the speed of the ball mill is 900rpm, ball milling time is 6 hours. Then disperse the ball-milled silicon oxide in a 0.5M sodium hydroxide solution to make a slurry, with the solid content controlled at 10wt%, and etch it on a magnetic stirrer for 3 hours. The slurry is washed and washed at 100°C. Vacuum drying treatment for 2 hours to obtain pretreated silicon oxide;

[0050] (2) Preparation of silicon oxide-based carbon precursor: under the protecti...

Embodiment 3

[0056] A method for preparing a siloxa-based carbon negative electrode material includes the following steps:

[0057] (1) Silica pretreatment: The silica powder with an average particle size of 5-20μm is calcined at 1200°C for 2 h under helium protection, and the heating rate is 5°C / min. When the furnace is cooled to room temperature, put the calcined silicon oxide into a ball mill (zirconia is the ball milling medium) for dry ball milling. The ball mill tank is filled with helium gas, the ball-to-battery ratio is 10:1, and the speed of the ball mill is 800 rpm, ball milling time is 5 h. Then, the ball-milled silicon oxide was dispersed in a 2M sodium hydroxide solution to make a slurry, the solid content was controlled at 5 wt%, and the slurry was etched on a magnetic stirrer for 1 hour. The slurry was washed and vacuumed at 70°C. Drying for 6 hours to obtain pretreated silicon oxide;

[0058] (2) Preparation of silicon oxide-based carbon precursor: under the protection of argo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com