Binder for silicon-based negative electrode material and preparation method of binder

A technology of silicon-based negative electrode materials and binders, applied in battery electrodes, structural parts, electrical components, etc., to achieve the effects of improving toughness, improving Coulombic efficiency and capacity retention, and improving the stability of low-shear regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

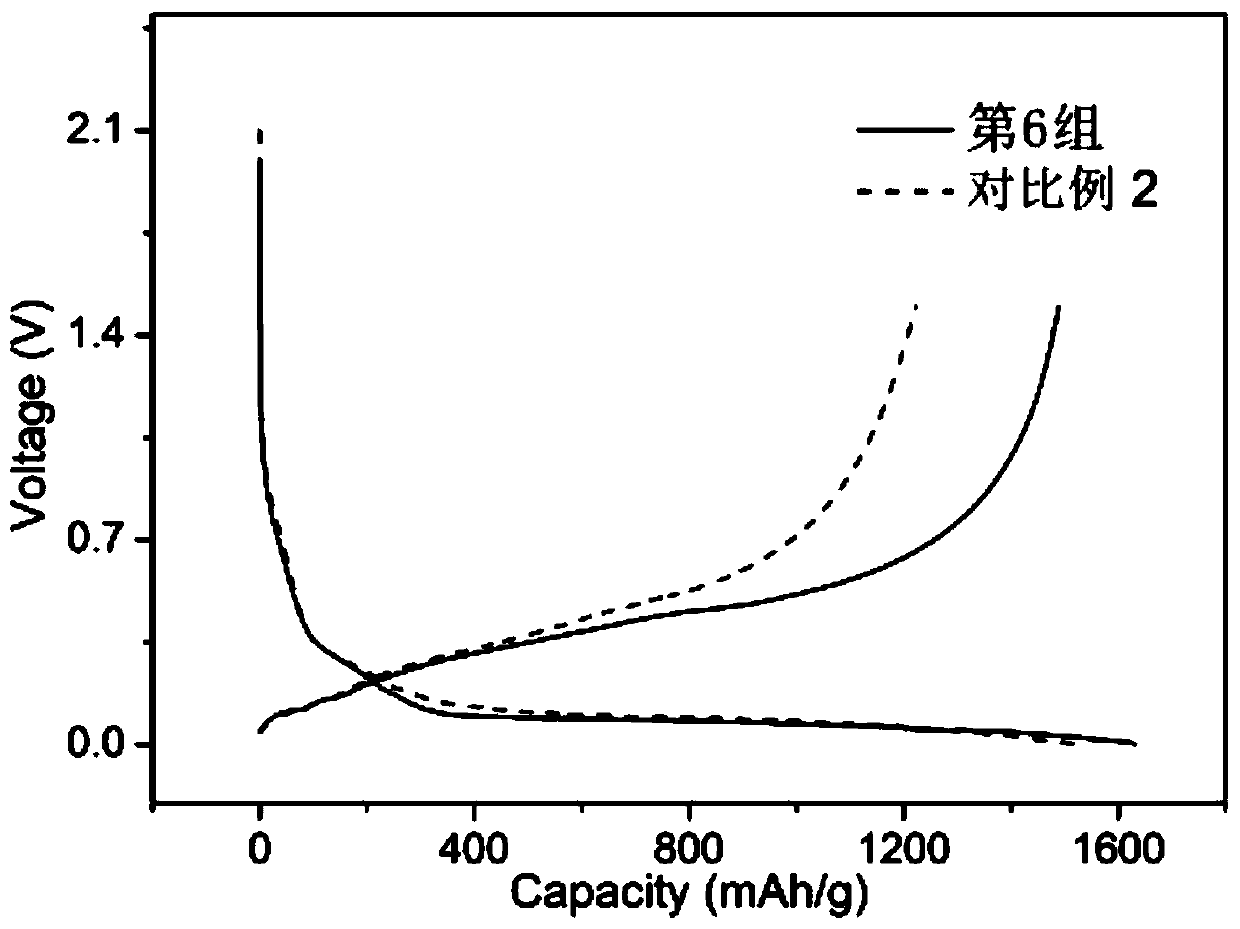

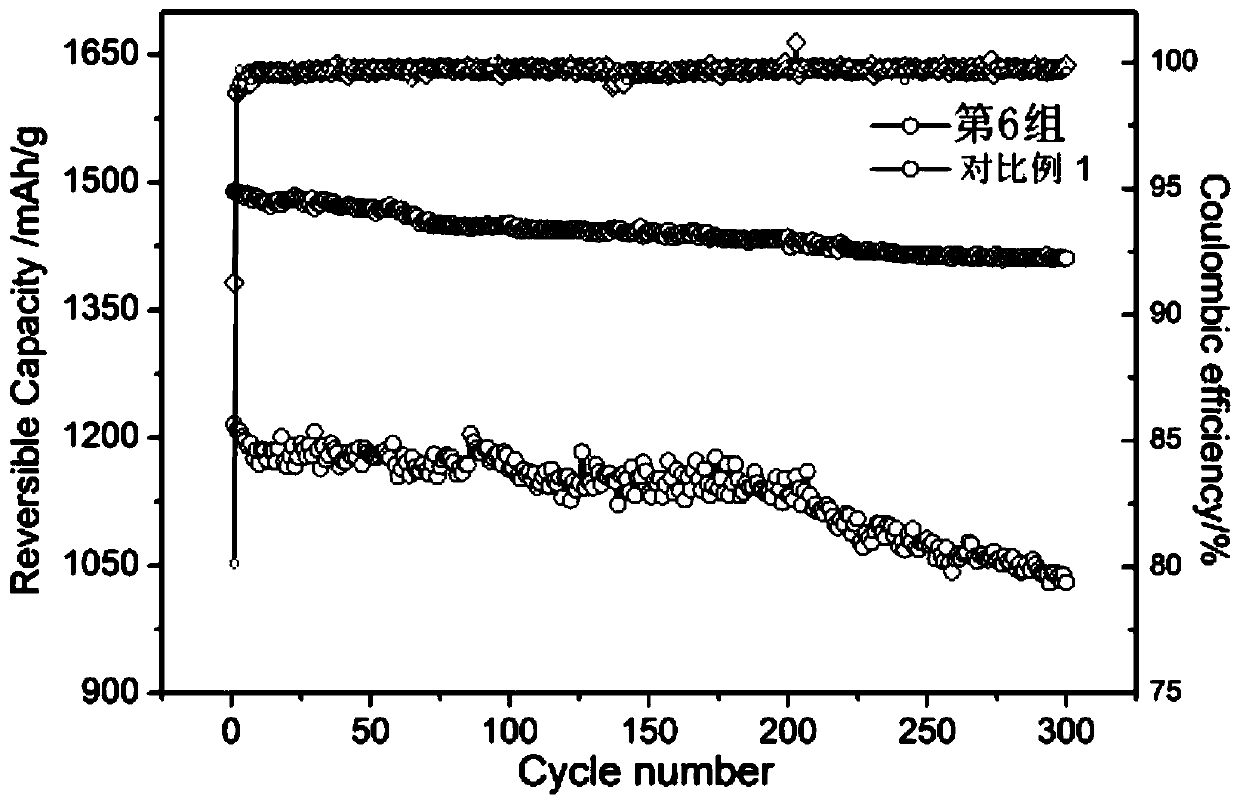

Examples

Embodiment 1

[0026] Modified PAA-Li adopts the following steps:

[0027] A lithium chloride saturated solution consisting of 55 vol% methanol, 25 vol% isopropanol and 20 vol% deionized water was formed at a temperature of 25°C. Disperse 50 g of PAA into 500 g of saturated lithium chloride solution, stir the resulting dispersion for 15 min, and separate the solid and liquid by filtration. The separated solid was redispersed into a saturated lithium chloride solution, stirred for 15 min, separated by filtration, and repeated three times. The separated product was washed with 500 g of solvent (20 vol% water, 55 vol% methanol and 25 vol% isopropanol), separated by filtration, and repeated three times. Dry at 55 °C for 12 h to obtain the final product.

Embodiment 2

[0029] Preparation of slurry:

[0030] (1) Weighing;

[0031] (2) Dissolve CMC and PAA-Li prepared in Example 1 in deionized water, and stir for at least 60 minutes to obtain a premix;

[0032] (3) Then add styrene-butadiene rubber (SBR) emulsion to the premix and stir for at least 30 minutes;

[0033] (4) Continue to add conductive agent and silicon-based negative electrode material (silicon carbon), and stir at high speed (10000rpm / min) for 1~2h.

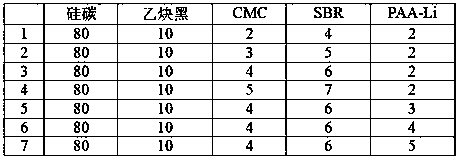

[0034] The more specific ratio is shown in the table below:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com