Silk thread package dynamic contact kinetic parameter testing device and method

A dynamic parameter and testing device technology, applied in the field of mechanical dynamics, can solve the problems of destroying the quality of the wire and failing to stabilize the wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

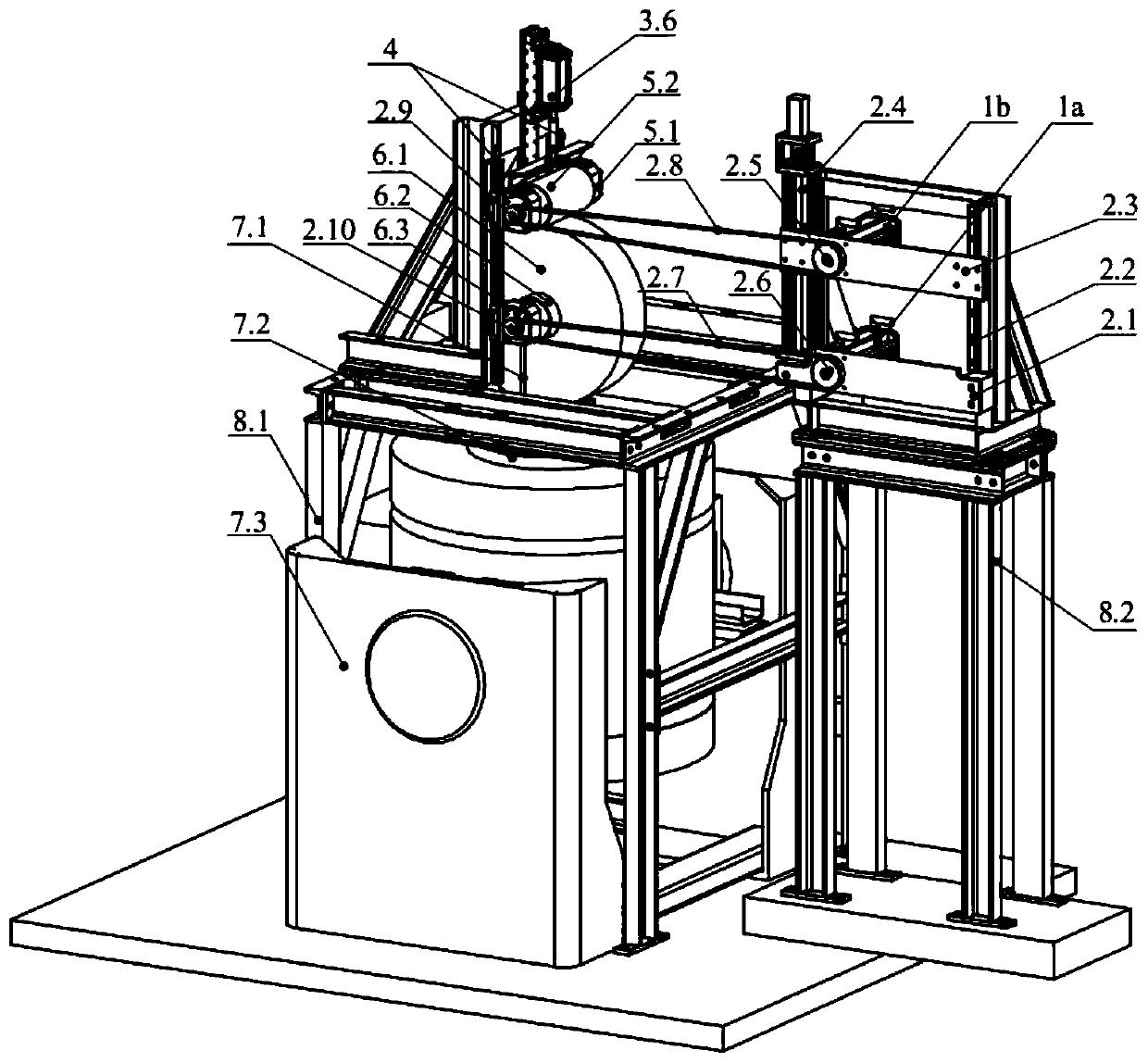

[0033] see figure 1 As shown, the test device for dynamic contact dynamic parameters between packages and contact rollers in the implementation of the present invention includes a power unit 1 for driving the spindle shaft (including packages) and contact rollers to rotate, and a transmission device with vibration isolation effect 2. Keep the pressure control air path with a certain contact pressure between the contact roller and the normal direction of the package 3. Maintain the vertical movement guide device of the "spindle-package-contact roller" system 4, the contact roller joint 5, the spindle and the coil Install the joint 6, the vibrating table 7 for driving the spindle shaft (including the package) to vibrate, and the support frame 8 for fixing the above-mentioned devices and parts.

[0034] see figure 2As shown, the support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com