Rigidity testing device of fixed type metal sheet stamping part

A testing device and metal sheet technology, applied in the direction of testing material hardness, etc., can solve the problems of no fixed metal sheet stamping rigidity testing device, inability to guarantee accuracy, non-standardization, scientific and other problems, to achieve compact structure and workability. Efficiency improvement, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

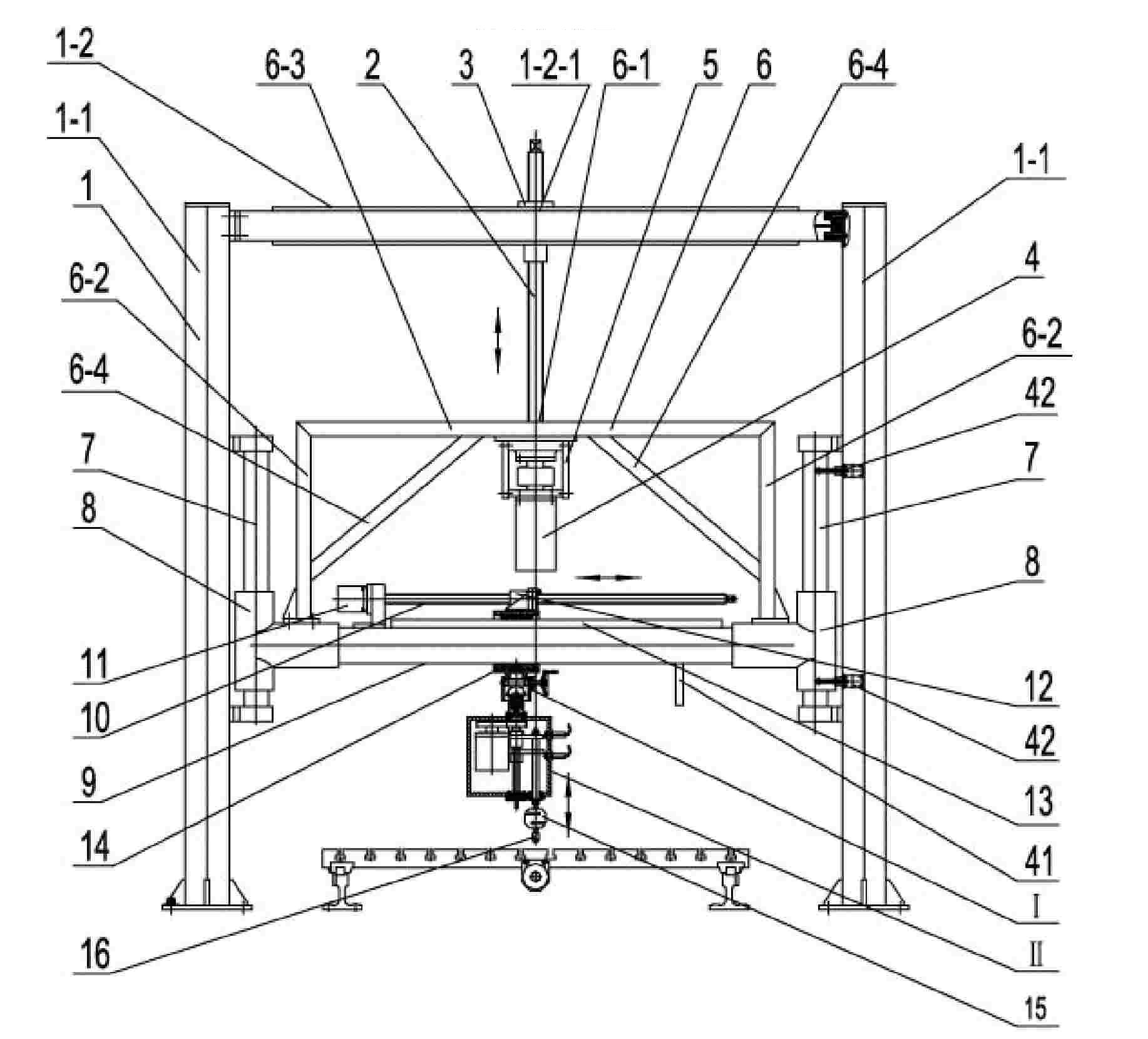

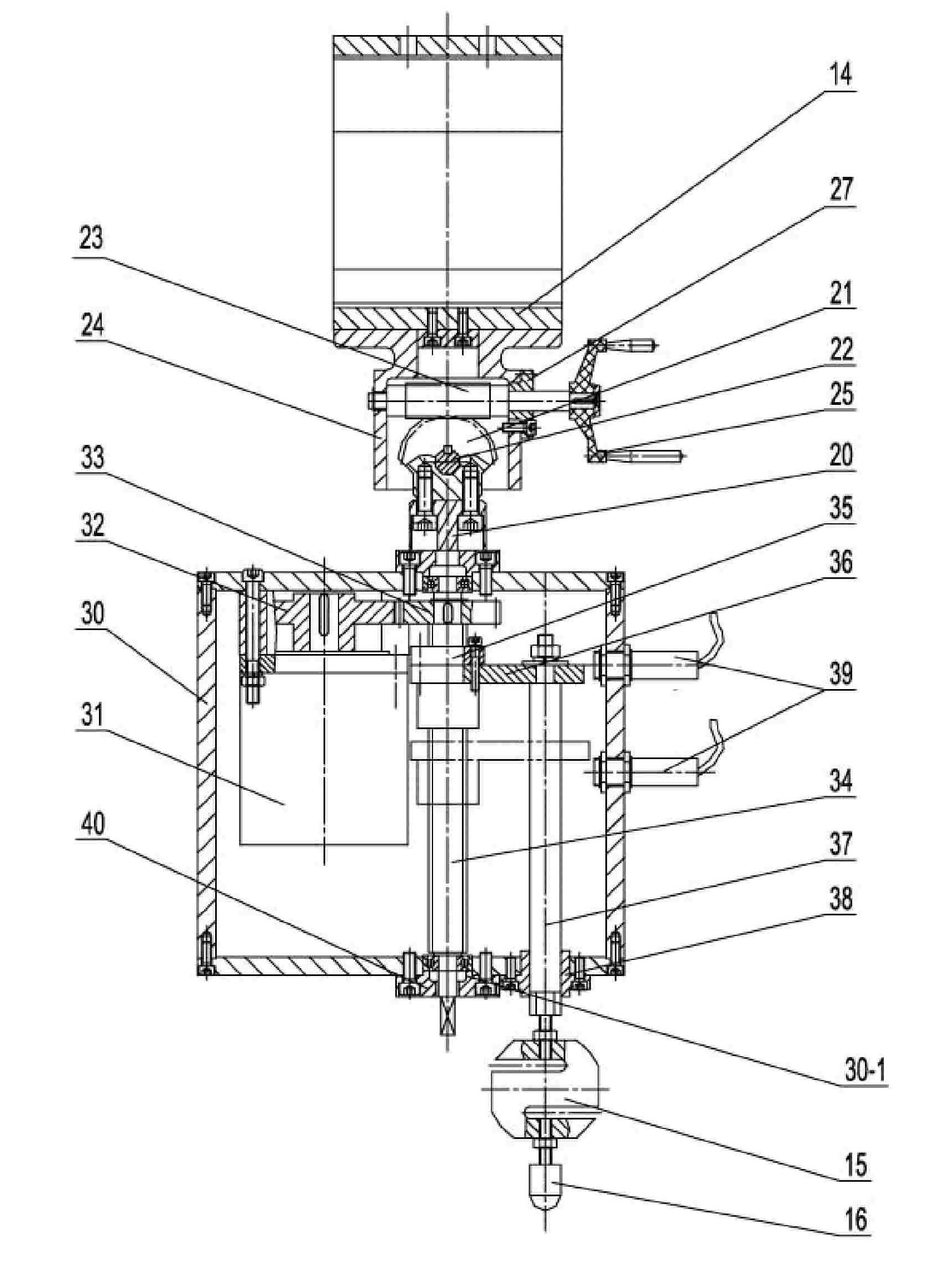

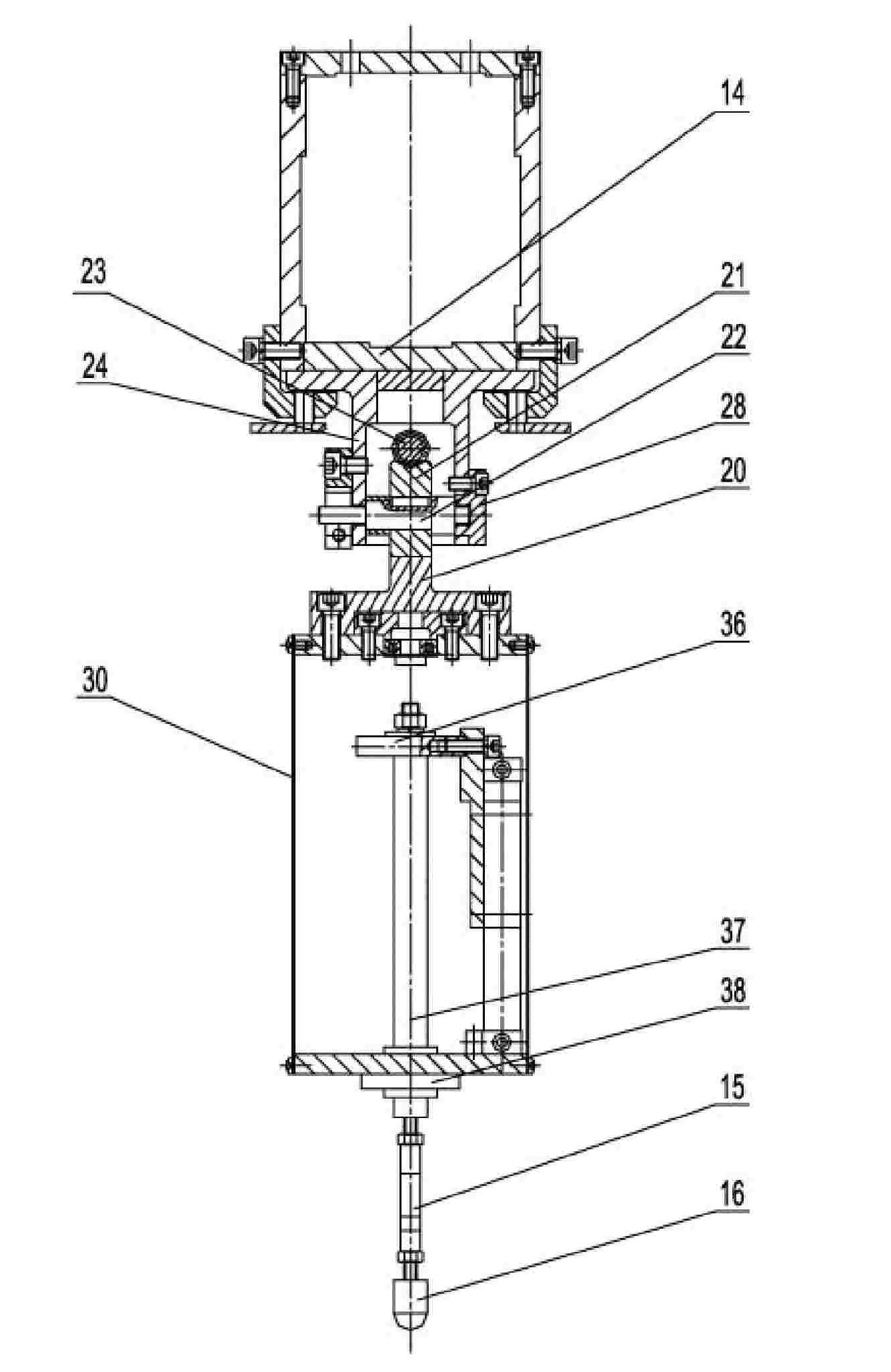

[0012] Specific implementation mode one: as Figure 1~3 As shown, the fixed sheet metal stamping parts rigidity testing device in this embodiment includes a frame 1, a first lead screw 2, a first screw nut 3, a first motor 4, a motor seat 5, a bracket 6, and two guide posts 7 , Two tee bushings 8, beam tube 9, second lead screw 10, second motor 11, second nut 12, guide rail 13, support slide 14, worm gear mechanism I, fine-tuning loading mechanism assembly II, A pressure sensor 15 and a pressure head 16, a first through hole 1-2-1 is opened on the beam 1-2 of the frame 1, and the first thread nut 3 is arranged in the first through hole 1 of the beam 1-2 - In 2-1, the upper part of the first lead screw 2 is screwed to the first screw nut 3, and the lower end of the first lead screw 2 passes through the second through hole 6-1 of the bracket 6 and connects with the first motor 4 The output shaft of the frame 1 is affixed, and the lower part of the bracket 6 is affixed to the fi...

specific Embodiment approach 2

[0017] Specific implementation mode two: as figure 1 As shown, the test device further includes an adjustment rod 41 , one end surface of the adjustment rod 41 is fixed on the outer surface of the beam tube 9 . With such a design, the rotation movement of the beam tube can be conveniently adjusted through the adjustment rod 41 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: as figure 1 As shown, the test device also includes two travel switches 42, and the two travel switches 42 are installed on any one of the two columns 1-1 of the frame 1 along the vertical direction, and are located on any one of the columns. and between a guide post 7 adjacent to it. Designed in this way, the two travel switches 42 can limit the travel of the three-way bushing 8 on the guide post 7, so as to play a protective role. Other components and connections are the same as those in the second embodiment.

[0019] working principle:

[0020]Most of the automobile panels are large-scale curved sheet stamping parts. When testing the stiffness of the sheet metal stamping parts, the automobile panels are placed horizontally on the workbench, and the periphery of the automobile panels is fixed with clamps. In order to find the normal position of the center of the automobile panels, First, the rotation of the first motor 4 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com