High-radial-stability elastic bearing

An elastic bearing and stable technology, applied in flexible bearings, bearings, bearing components, etc., can solve the problems of rubber layer performance decline, life reduction, fatigue failure, etc., to improve stability, reduce strain energy density, and improve overall life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

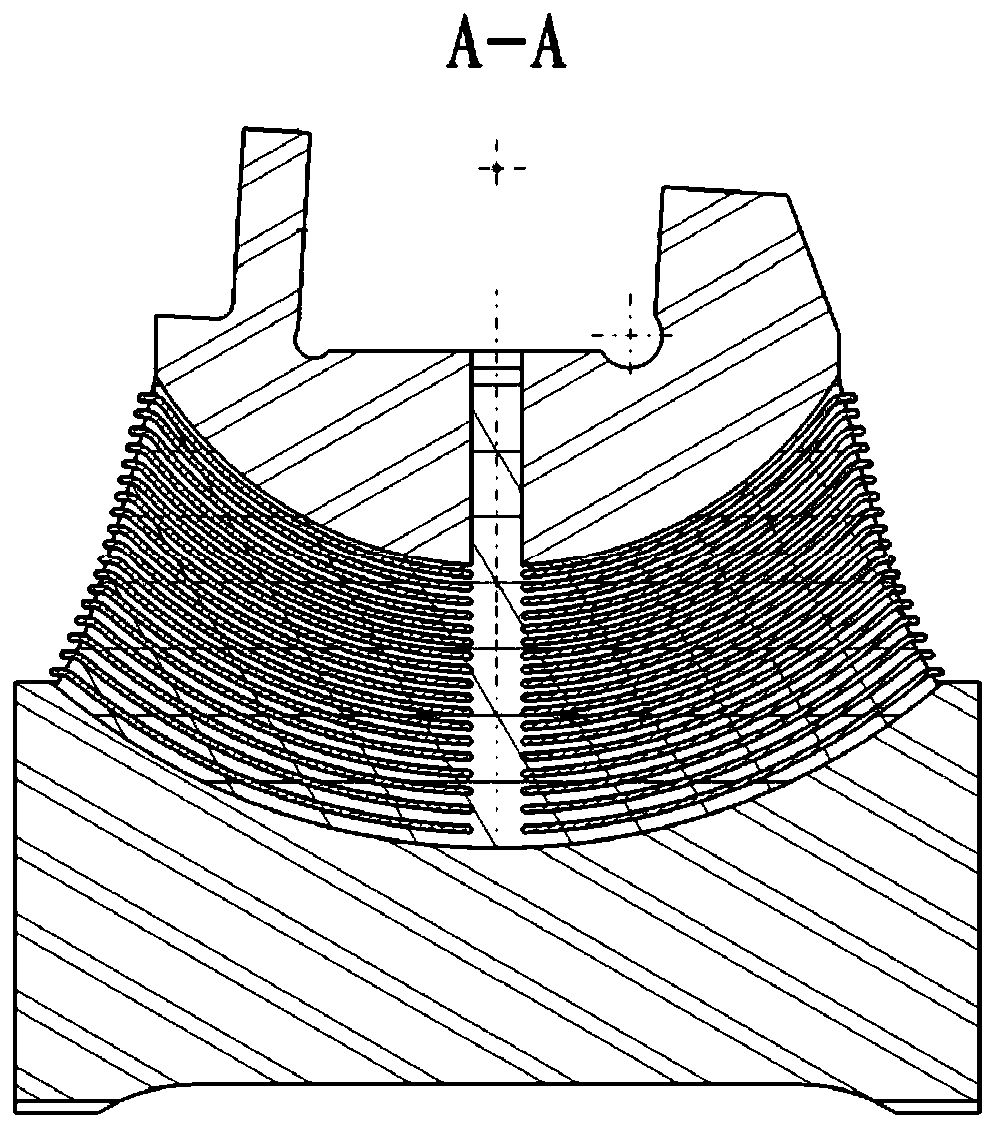

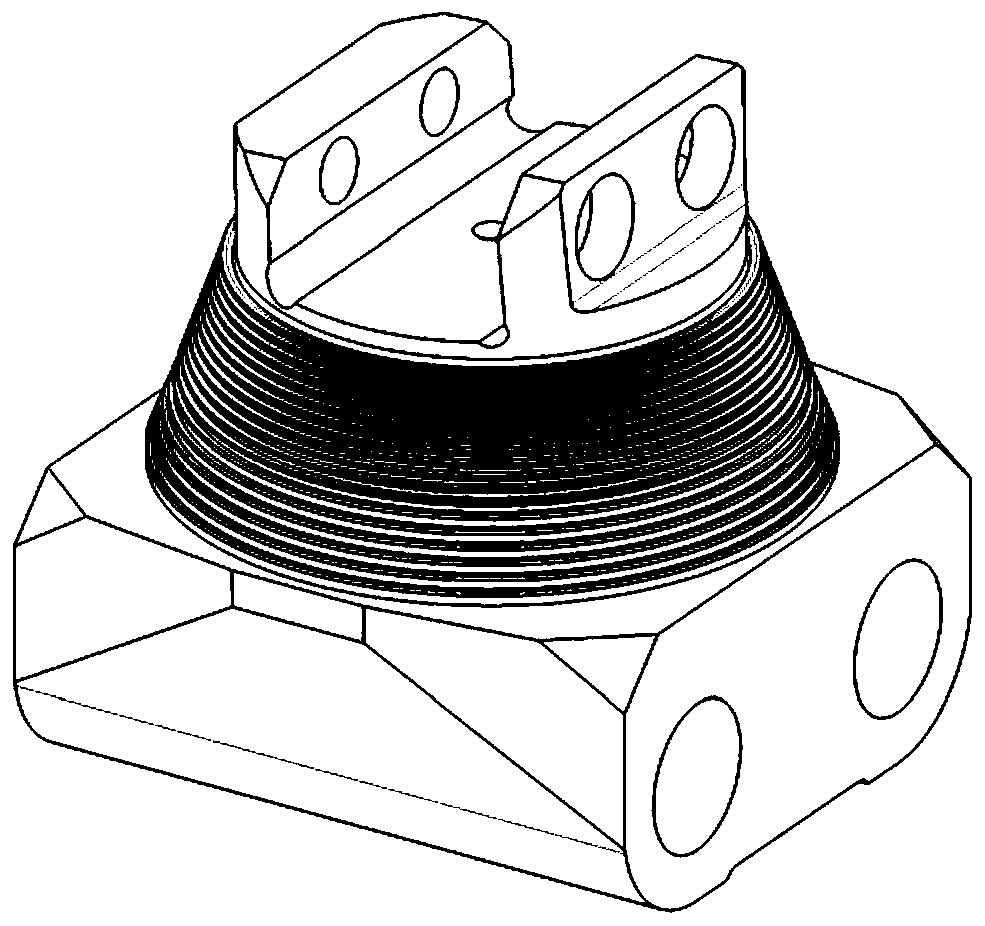

[0030] A high radial stability elastic bearing, such as Figure 2 ~ Figure 4 shown. The small joint 1, the intermediate transition rigid part 4 and the large joint 7 are made of aluminum alloy. The first center spherical rubber layer 3 and the second center spherical rubber layer 5 adopt NR1055 natural rubber compound.

[0031] The spherical radius of the concave surface of the intermediate transition rigid member 4 is 68.3mm, the spherical radius of the convex surface is 62.5mm, and the distance between the centers of the two spherical surfaces is 10mm.

[0032] The set of the first center spherical rigid spacer 2 has 12 layers in total, and the thickness of the first center spherical rigid spacer 2 is 0.8mm.

[0033] A set of second sphere-centered spherical rigid spacers 5 has 5 layers in total, and the thickness of the second sphere-centered spherical surface rigid spacers 5 is also 0.8 mm.

[0034]In order to facilitate the comparison of the improvement of the radial r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com