Multi-layer co-extrusion anti-polarization type composite adhesive film and preparation method thereof

A multi-layer co-extrusion and anti-polarization technology, which is applied in the direction of adhesives, films/sheets without carriers, photovoltaic power generation, etc., can solve the problem of reducing the light transmittance and volume resistivity of adhesive films, reducing the power generation efficiency of cells, and reducing components. Power generation efficiency and other issues, to achieve the effect of reducing light transmittance and volume resistivity, improving anti-PID performance, and reducing power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

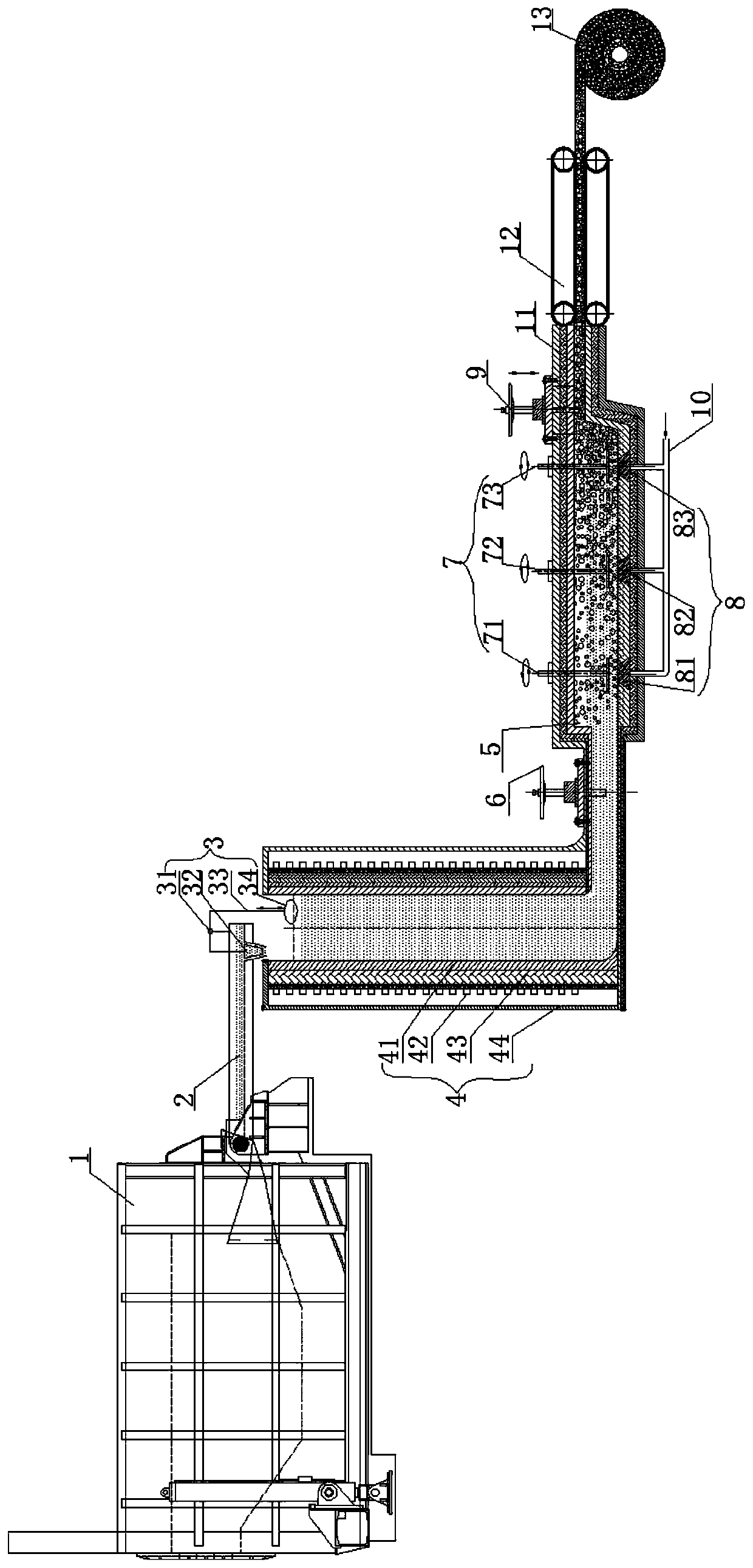

Method used

Image

Examples

Embodiment approach 1

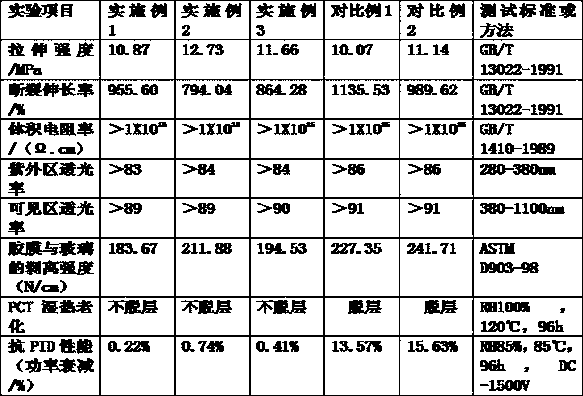

[0024] POE resin adopts melt flow rate of 18g / 10min, light transmittance > 90%, volume resistivity ≥ 1.0×10 15 , pellets with a melting temperature of 64°C, control the extrusion thickness of the POE resin layer to 0.25mm; the EAA anti-polarization layer uses EAA resin, the EAA resin uses acrylate content of 30%, the melting point is 65°C, and the melt index is 11g / 10min pellets, control the extrusion thickness of the EAA layer to 0.3mm; EVA resin adopts a melt flow rate of 25g / 10min, light transmittance > 86%, volume resistivity ≥ 1.0×10 14 , with a melting temperature of 56°C and a VA content of 28%, the extruded thickness of the EVA resin layer is controlled to be 0.25mm; the POE resin layer, the copolymer resin anti-polarization layer and the EVA resin layer are respectively produced by three single-screw extruders Extruded to the same three-layer co-extrusion die head, the extrusion temperature is 80-100°C, and the three-layer material is extruded from the die head to pr...

Embodiment approach 2

[0026] The melt flow rate of POE resin is 14g / 10min, the light transmittance is >90%, and the volume resistivity is ≥1.0×10 15 , pellets with a melting temperature of 58°C, the extruded thickness of the POE resin layer is controlled to be 0.3mm; the EAA anti-polarization layer is made of EMA resin, the EMA resin is made of acrylate content of 25%, the melting point is 63°C, and the melt index is 15g / 10min pellets, control the extrusion thickness of the EMA layer to 0.2mm; EVA resin adopts a melt flow rate of 20g / 10min, light transmittance > 91%, volume resistivity > 1.0×10 14 , with a melting temperature of 54°C and a VA content of 25%, the extrusion thickness of the EVA resin layer is controlled to be 0.3mm; the POE resin layer, the copolymer resin anti-polarization layer and the EVA resin layer are respectively produced by three single-screw extruders Extruded to the same three-layer co-extrusion die head, the extrusion temperature is 80-100°C, and the three-layer material ...

Embodiment approach 3

[0028] POE resin adopts melt flow rate of 18g / 10min, light transmittance > 90%, volume resistivity ≥ 1.0×10 15 , pellets with a melting temperature of 64°C, control the extruded thickness of the POE resin layer to 0.3mm; the EAA anti-polarization layer uses PTW resin, the PTW resin uses acrylate content of 28%, the melting point is 69°C, and the melt index is 8g / 10min pellets, control the extrusion thickness of PTW layer to 0.3mm; EVA resin adopts melt flow rate of 25g / 10min, light transmittance> 86%, volume resistivity ≥ 1.0×10 14 , with a melting temperature of 56°C and a VA content of 28%, the extruded thickness of the EVA resin layer is controlled to be 0.3mm; the POE resin layer, the copolymer resin anti-polarization layer and the EVA resin layer are respectively produced by three single-screw extruders Extruded to the same three-layer co-extrusion die head, the extrusion temperature is 80-100°C, and the three-layer material is extruded from the die head to prepare a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com