A processing method for droplet cake-like bouncing large-scale superhydrophobic cone-column array

A processing method and large-scale technology, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of inability to process super-hydrophobic cone-column arrays in large quantities for a long time, poor strength and durability, and low processing efficiency. Ease of large-area processing, large processing size, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

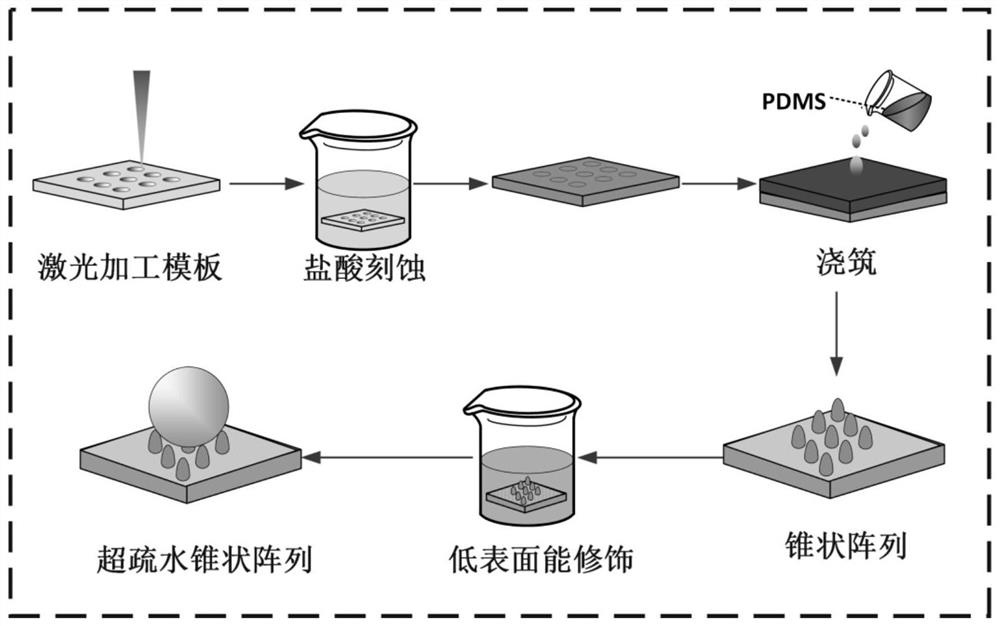

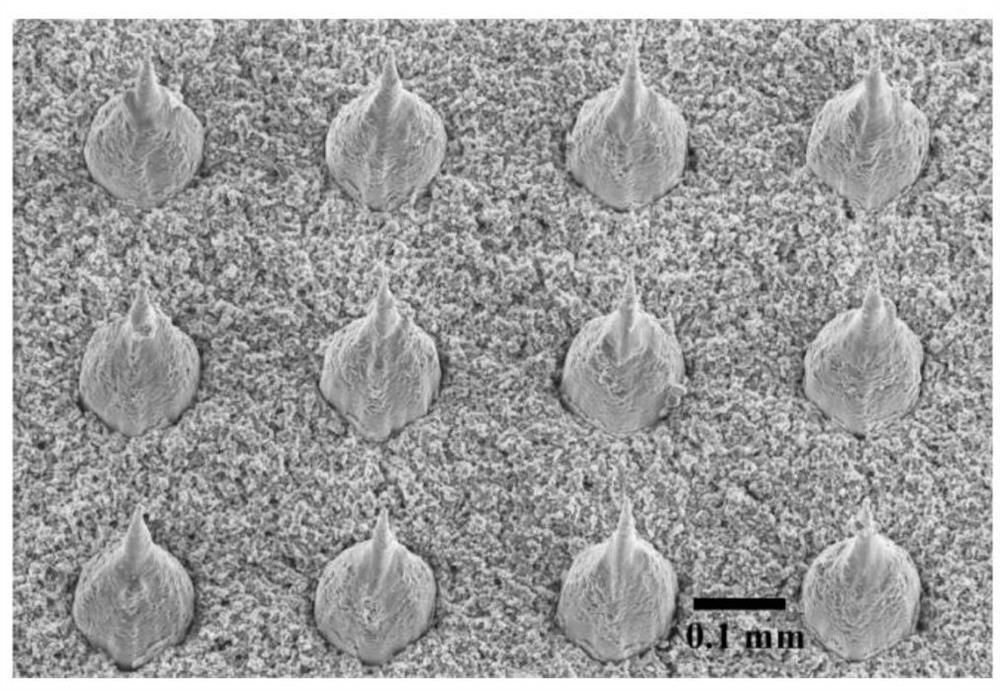

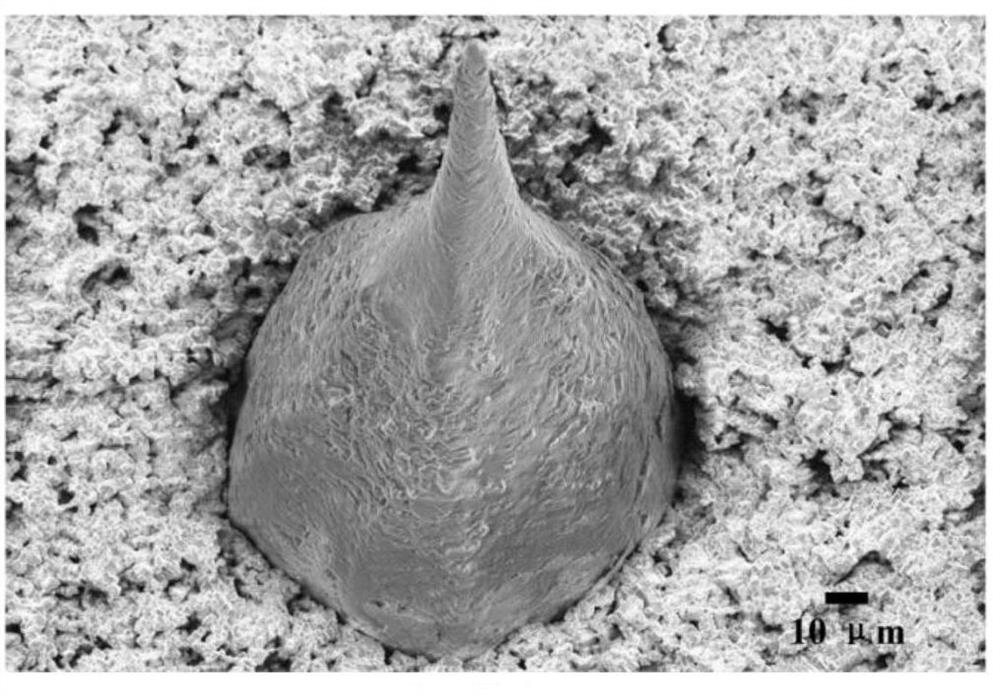

[0023] Using the mold replication method to process large-scale superhydrophobic cone-column arrays with droplet cake bounce, such as figure 1 As shown, the specific method is as follows:

[0024] (1) Mold processing: remove the protective film on the surface of the 1060 aluminum plate, adjust the laser so that its focus is on the surface of the aluminum plate; draw a 5×5 circular array with a diameter of 0.8mm and a center distance of 1.0mm, and set the laser processing power to 24W and scanning speed 100mm / s, frequency 20kHz, and 60 strikes for marking processing; then placed in 0.4mol / L HCl solution for etching for 2min, then ultrasonically cleaned with deionized water, and dried;

[0025] (2) Casting and curing: mix the PDMS main agent and cross-linking agent evenly at a mass ratio of 10:1, pour the prepared casting mold, and perform defoaming treatment in a vacuum environment, and cure at 70°C for 4 hours; directly demould to obtain PDMS Array of cones.

[0026] (3) Low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com