Preparation method of three-dimensional large-scale high-precision microfluidic channel

A microfluidic channel, high-precision technology, used in chemical instruments and methods, laboratory containers, laboratory utensils, etc. Test and other problems, to achieve the effect of stable and controllable closing ability, no cracks, and stable processing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Ultrashort Pulse Laser Irradiation

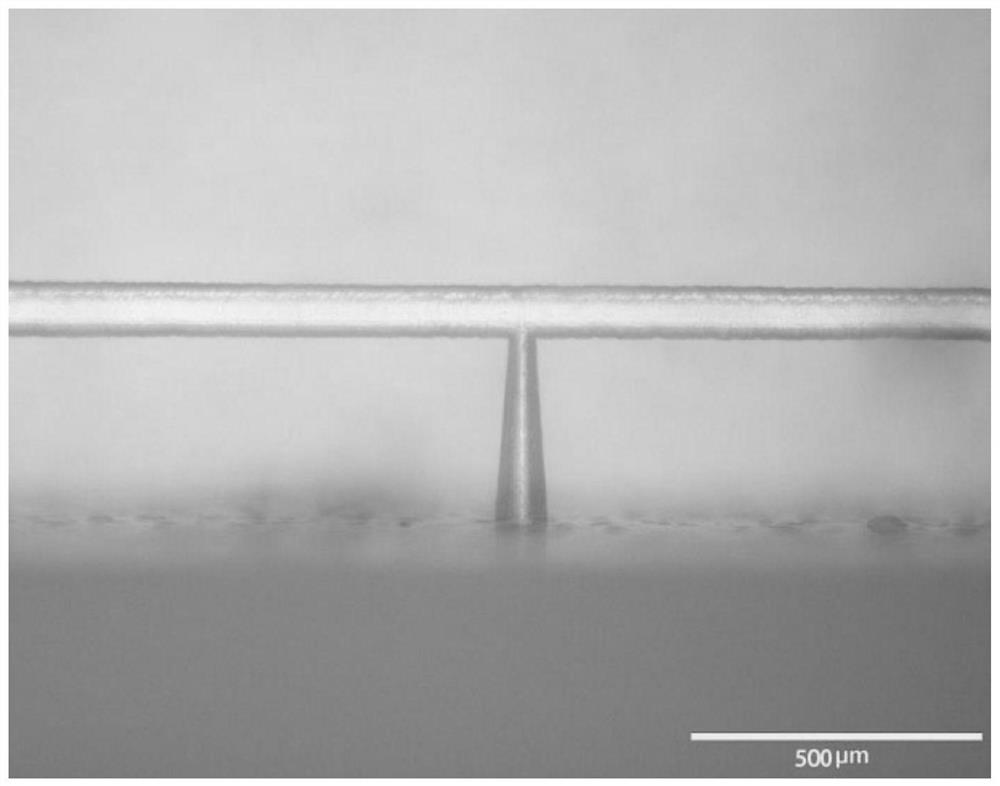

[0030] Such as figure 1 As shown, a clean quartz glass sample with dimensions of 100 mm × 5 mm × 2 mm and polished six sides was taken and fixed on a three-dimensional translation stage; the center wavelength of the laser was 1026 nm, the repetition frequency was 250 kHz, and the pulse width was 270 fs ; Use a microscope objective lens with a numerical aperture of 0.25 to focus the laser to directly write the modified pattern. Using linearly polarized light processing, the polarization direction is perpendicular to the direct writing direction. The length of the direct-written three-dimensional U-shaped microchannel pattern is ~80 mm, and it is located 300 μm below the surface of the quartz glass. The lengths of multiple auxiliary channel patterns connecting the sample surface and the microchannel are all 300 μm, and the spacing between the auxiliary channels is 1 mm. The average power of laser irradiation was 800 mW, and t...

Embodiment 2

[0036] Step 1: Ultrashort Pulse Laser Irradiation

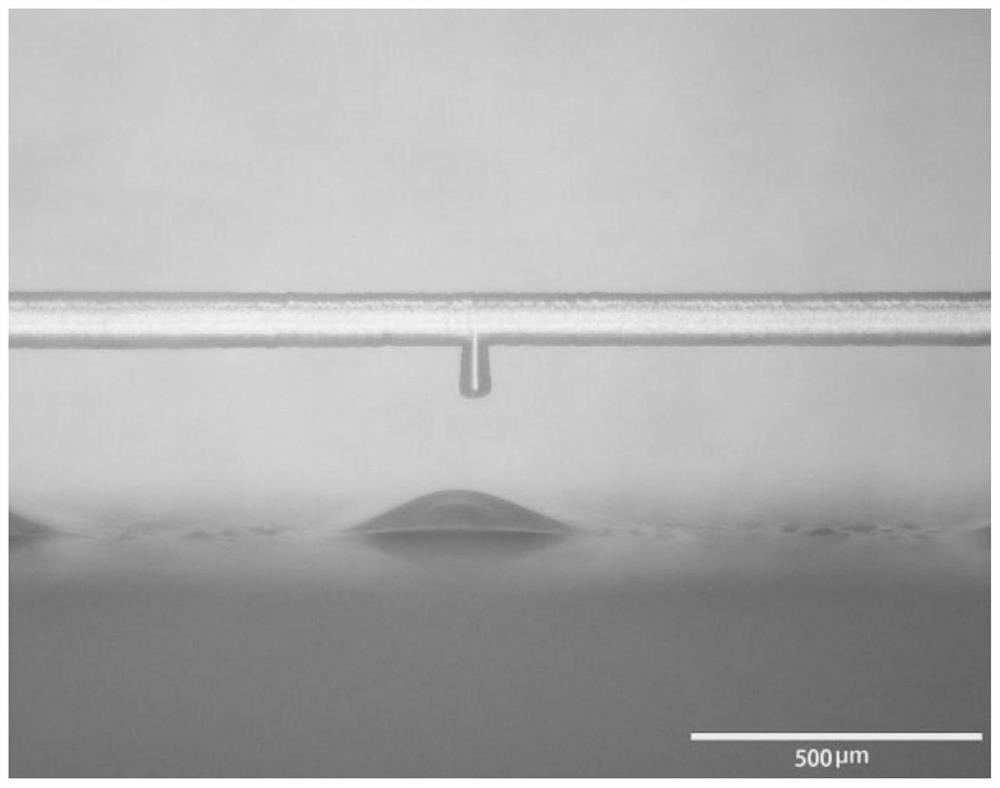

[0037] A clean quartz glass sample with a size of 20 mm×10 mm×2 mm and polished six sides was taken and fixed on a three-dimensional translation stage; the center wavelength of the laser was 1026 nm, the repetition frequency was 250 kHz, and the pulse width was 270 fs; A microscopic objective lens with an aperture of 0.25 focuses the laser light, and a quarter-wave plate is placed in front of the focusing objective lens to generate circularly polarized light, and then write three-dimensional modified patterns directly. The lateral length of the direct-written spiral channel pattern is ~10 mm, the pattern edge is located 200 μm below the surface of the quartz glass, the spiral diameter is 300 μm, and the pitch is 500 μm. The single length of the direct-written auxiliary channel connecting the sample surface and the helical microchannel is 200 μm, and the distance between two adjacent channels is 500 μm. The average power of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com