Preparation method of biological calcium composite super absorbent resin

A technology of super absorbent resin and biological calcium, applied in the field of organic-inorganic composite hydrogel, can solve the problems of pollution, waste of resources and environment, low utilization rate of development, etc., and achieve the effect of saving fossil energy and enriching porous structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

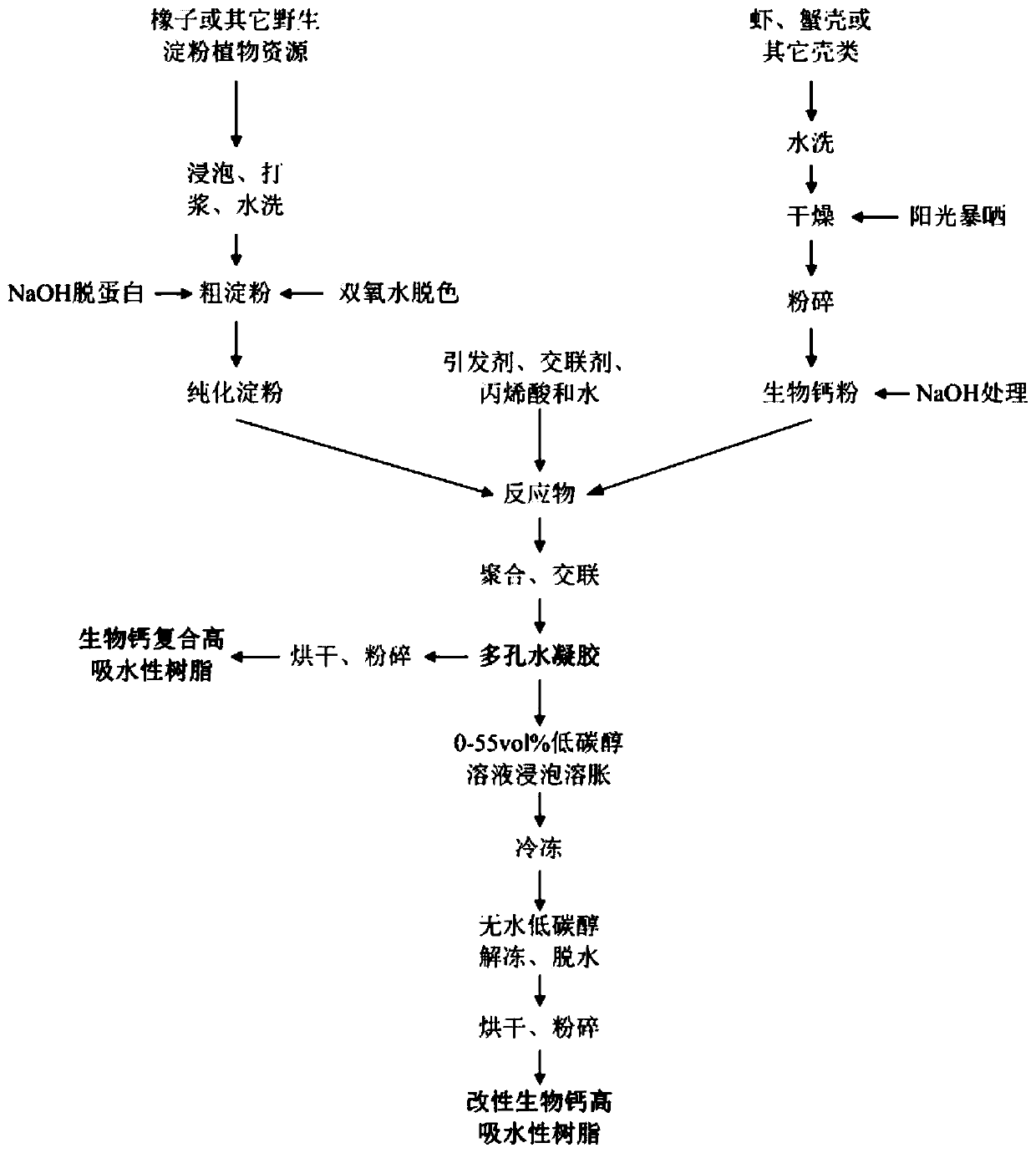

[0033] A preparation method of biological calcium composite superabsorbent resin, comprising the steps of:

[0034] a. Disperse 0.5-3 parts by mass of biopolymer in an appropriate amount of pure water and stir, then mix 0.4-6 parts by mass of bio-calcium powder with 2-12 parts by mass of NaOH, add appropriate amount of pure water to make a paste, and After heat preservation treatment, add the above-mentioned biopolymer solution or directly add the above-mentioned biopolymer solution, and stir to make the bio-calcium powder and the biopolymer disperse completely evenly;

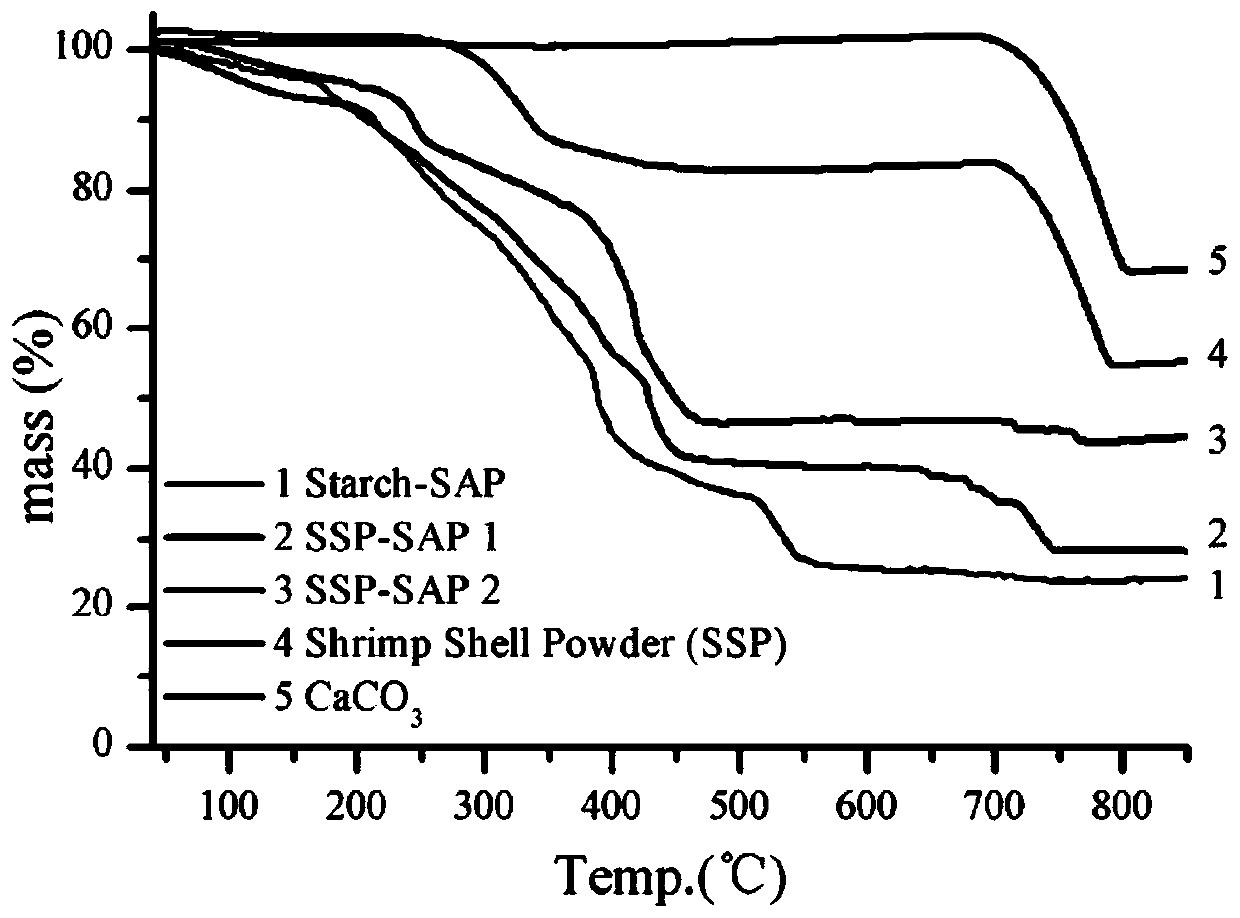

[0035] In the present invention, the biological calcium powder prepared from chitin-containing raw materials such as shrimp and crab shells is preferably mixed with NaOH to carry out a certain heat preservation treatment, so that the chitin contained in the calcium powder can undergo deacetylation reaction. Chitin can be introduced into the gel network, the content of inorganic substances in the product is hig...

Embodiment 1

[0041] Weigh 0.4 parts of shrimp shell powder (SSP), 1.2 parts of acorn starch, add 10 parts of pure water to make a paste, add 3.2 parts of NaOH while stirring, and add 14.4 parts of acrylic acid (AA), 0.1 1 part of ammonium persulfate (APS), 0.02 part of N,N'-methylenebisacrylamide (MBA) and 68.68 parts of pure water, stirred evenly and placed in a water bath at 65°C for 5 hours; the gel formed after the reaction Cut into two pieces of equal quality, place one piece at 65°C for 12 hours, and obtain 9.46 parts of super absorbent resin (yield: 98%); the water absorption rate in pure water is 419±3g / g. The other piece of hydrogel was directly frozen in a refrigerator at -18°C. After it was completely frozen, it was taken out and directly immersed in absolute ethanol for dehydration. After the dehydration was complete, it was dried at 65°C for 12 hours. After crushing, 9.17 parts of physically modified superabsorbent were obtained. Resin (yield 95%); the water absorption rate in...

Embodiment 2

[0043]Weigh 2.0 parts of shrimp shell powder, add 1.2 parts of acorn starch, add 10 parts of pure water to make a paste, add 3.2 parts of NaOH while stirring, add 14 parts of acrylic acid (AA), 0.08 parts of Ammonium sulfate (APS), 0.02 parts of N,N'--methylenebisacrylamide (MBA) and 69.5 parts of pure water, stirred evenly and placed in a water bath at 65°C for 5 hours; the gel formed after the reaction was immersed in 2 times the mass of 10vol% ethanol aqueous solution, after it fully absorbs water and swells, put it in a -18°C refrigerator to freeze, take it out after complete freezing and immerse it in absolute ethanol for dehydration, and place it at 65°C for 12 hours after dehydration is complete. After crushing, 19.30 parts of physically modified superabsorbent resin were obtained (yield 94.2%); the water absorption ratios in pure water, tap water, normal saline and artificial urine were 2097±252, 423±3.5, 96.9±6.9 and 101.8±0.6 respectively g / g, the resin has good wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com