3D Te nanowire aerogel, and preparation method and application of aerogel

A nanowire and airgel technology, applied in the field of Te nanowire three-dimensional airgel, can solve the problems of cumbersome steps and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a Te nanowire three-dimensional airgel, comprising the following steps:

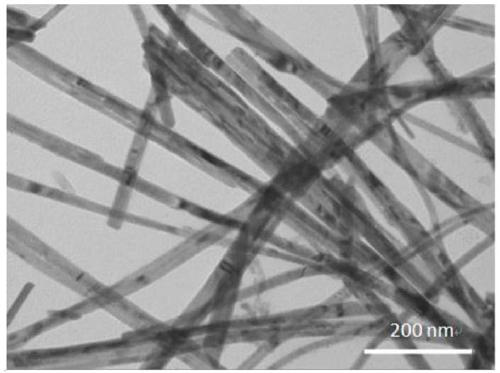

[0027] Disperse one-dimensional Te nanowires in an alcoholic solvent, preassemble with lead nitrate and perform hydrothermal reaction in an autoclave to obtain Te nanowire three-dimensional hydrogel;

[0028] The Te nanowire three-dimensional hydrogel is supercritically dried to obtain the Te nanowire three-dimensional airgel.

[0029] The invention firstly provides one-dimensional Te nanowires, then redisperses the one-dimensional Te nanowires into ethylene glycol, adds lead nitrate to pre-assemble the nanowires, then pours the solution into the substrate of the reaction kettle, and reacts under high temperature and high pressure After a period of time, a macroscale three-dimensional Te wire hydrogel is formed, and the hydrogel is supercritically dried with carbon dioxide to obtain a macroscale three-dimensional Te wire aerogel. The method is simple ...

Embodiment 1

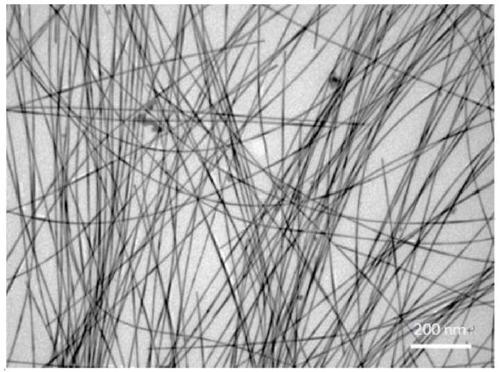

[0043] Synthesis of Tellurium Nanowires with a Diameter of 7nm

[0044] Add 0.922g of sodium tellurite, 10g of polyvinylpyrrolidone, and 330mL of deionized water into a 500mL reactor and stir to dissolve, then add 33.5mL of ammonia water and 16.5mL of hydrazine hydrate, stir for 10 minutes, and then put it in an oven at 180°C for 3 hours. Take out the reaction kettle and let it cool down to room temperature naturally.

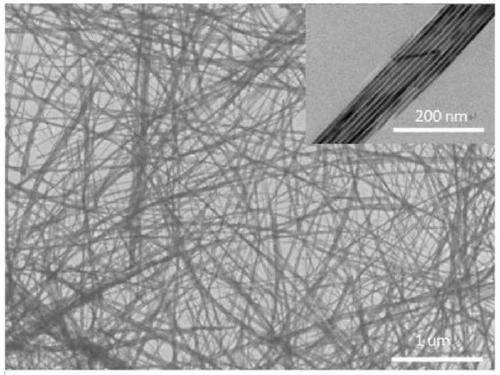

[0045] Synthesis of 3D Te Nanowire Hydrogels

[0046] Add 0.52g of 500mL of Te nanowires obtained by the above preparation method to centrifuge and precipitate with acetone, wash with ethanol and centrifuge again, disperse in 40mL of ethylene glycol, add 1g of lead nitrate, stir until the lead nitrate is completely dissolved, put in 50mL of reaction Heat in water at 120° C. for 36 hours in a kettle, and take out after cooling to obtain a three-dimensional Te nanowire hydrogel. After supercritical carbon dioxide drying, three-dimensional Te nanowire aerogels w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com