Novel water-based flexo printing process

A flexographic printing and process technology, applied in the field of new water-based flexographic printing technology, can solve the problems of reducing the printing rate, technical personnel have no reference, non-toxic materials are not described in detail, etc., to achieve auxiliary printing operations, increase Long service life, uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

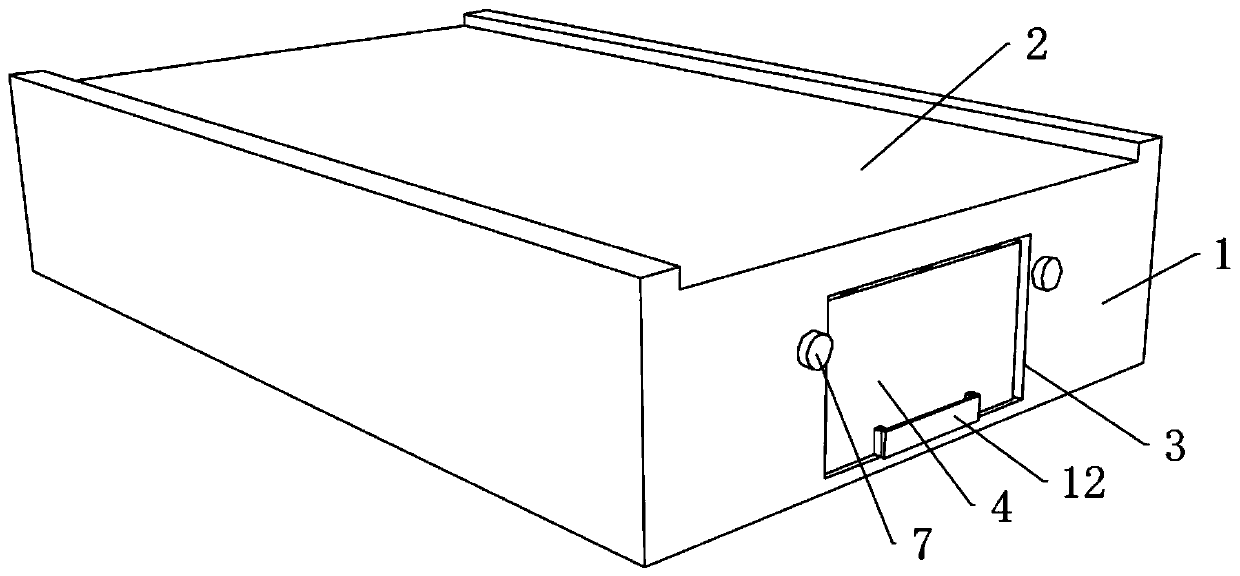

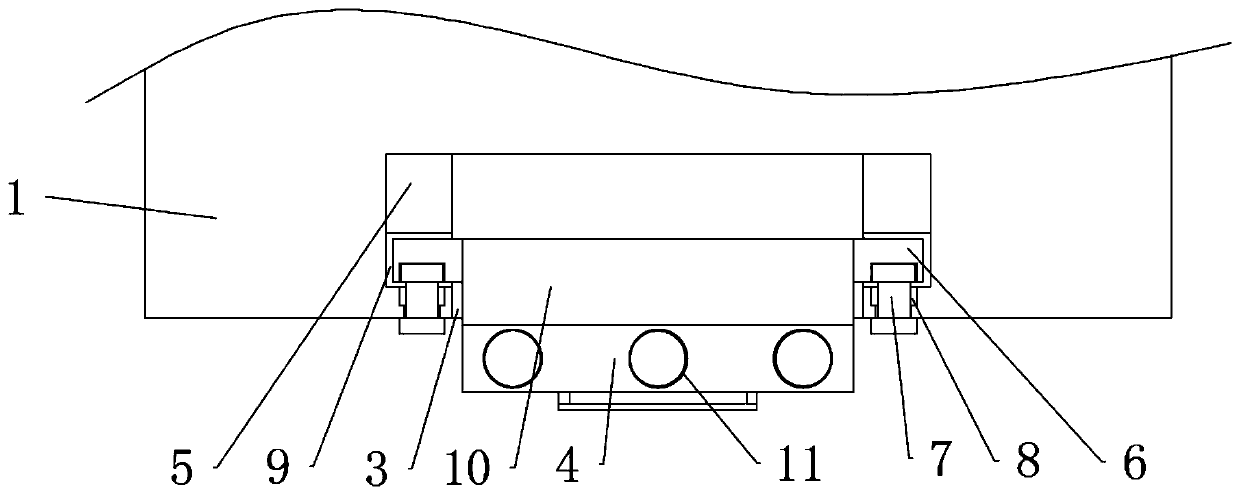

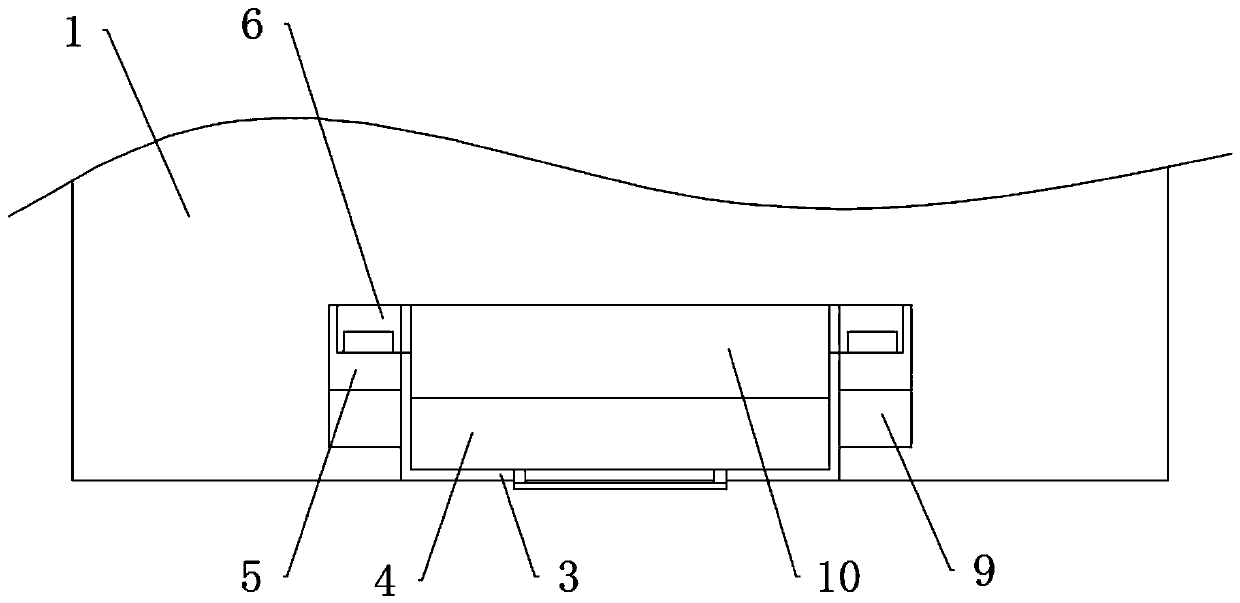

Image

Examples

Embodiment 1

[0049] A new water-based flexographic printing process, the operation steps of the printing process are:

[0050] Step 1. The staff cuts the film, and cuts off the blank part of the film of the printed original. After the cutting is completed, the staff performs the imposition and printing operations.

[0051] Step 2: Rinse and clean the printing plate with a developing solution, and use a fine brush to dip dilute sulfuric acid in the scratch to repair the printing plate. The ratio of dilute sulfuric acid is: the ratio of 95% concentrated sulfuric acid to water is: 1:100.

[0052] Step 3: Use a revision pen to remove the film edge marks on the printing plate, and wipe off the dirt on the printing plate in time during the revision process, and check the quality of the printing plate again after the revision is completed.

[0053] Step 4, printing on the printing plate through the printing material, including reverse printing.

[0054] Step 5. After printing the printing mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com