Lift pin and vacuum treatment device

A lifting pin, non-processing technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of poor etching uniformity, plasma unevenness, bad, etc., and achieve the effect of suppressing scars and achieving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

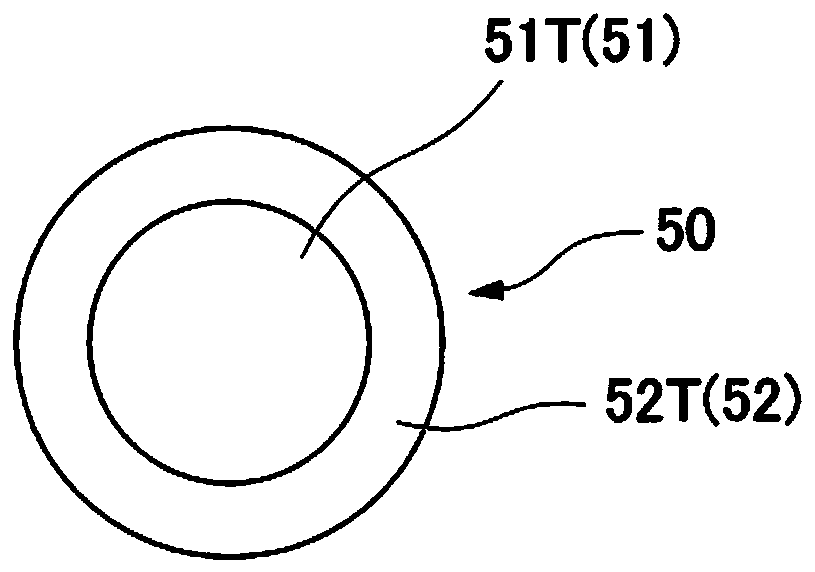

[0091] Image 6 It is a cross-sectional view showing main parts of a lift pin structure according to Modification 1 of the embodiment of the present invention. exist Image 6 In , the same reference numerals are assigned to the same components as those in the above-mentioned embodiment, and description thereof will be omitted or simplified.

[0092] This modification 1 is different from the above-mentioned embodiment in that the central member and the peripheral members are an integral body formed of conductive members.

[0093] Specifically, the lift pin 150 has a central region 151 (central member) and a peripheral region 152 (peripheral member), and is an integral body made of aluminum (conductive member). That is, no boundary is formed between the central area 151 and the peripheral area 152 . Although an aluminum oxide film (electrical insulation portion) formed by anodizing aluminum is formed on the first surface 151T of the central region 151 and the second surface 1...

Deformed example 2

[0100] Figure 7 It is a cross-sectional view showing main parts of a lift pin structure according to Modification 2 of the embodiment of the present invention. exist Figure 7 In , the same reference numerals are assigned to the same components as those in the above-mentioned embodiment and Modification 1, and description thereof will be omitted or simplified.

[0101] The second modification example differs from the above-described embodiment in that the surrounding members are conductive members.

[0102] Specifically, the lift pin 250 includes the above-mentioned central member 51 and a surrounding member 252 made of aluminum (conductive member). That is, in Modification 2, the peripheral member 252 made of aluminum is used instead of the peripheral member 52 made of insulating ceramics.

[0103] On the second surface 252T of the peripheral member 252, an aluminum oxide film (electrical insulation portion) formed by anodizing aluminum is formed, but the surface roughnes...

Deformed example 3

[0110] Figure 8 It is a cross-sectional view showing main parts of a lift pin structure according to Modification 3 of the embodiment of the present invention. exist Figure 8 In , the same reference numerals are assigned to the same components as those in the above-mentioned embodiment and Modifications 1 and 2, and description thereof will be omitted or simplified.

[0111] In the above embodiment, if Figure 3A , Figure 3B , Image 6 and Figure 7 As shown, the central member 51 and the peripheral member 52 are adjacent so that the end of the first surface 51T is in contact with the end of the second surface 52T. The present invention is not limited to Figure 3A , Figure 3B , Image 6 and Figure 7 structure shown. For example, if Figure 8 As shown, the second surface 52T and the first surface 51T may also be connected via a step ST. In this case, a concave portion 55 is formed between the upper end 52U of the surrounding member 52 and the first surface 51T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com