A method for removing an end piece and an apparatus for processing a substrate

A technology of edge material and substrate, applied in glass cutting devices, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as poor yield, and achieve the effect of suppressing scars such as sheath tails or gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0041] Hereinafter, a first embodiment of the method of removing the method of the boundary portion of the present invention will be described in detail with reference to the drawings.

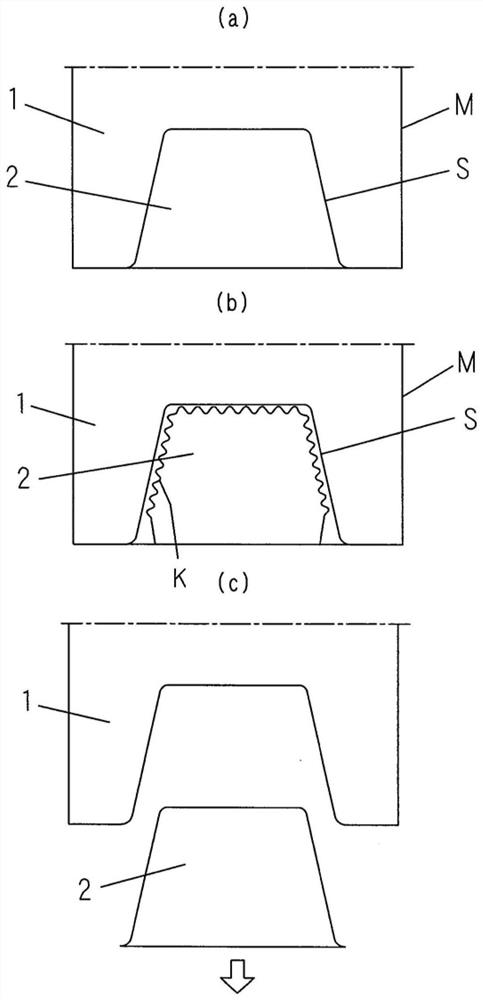

[0042] image 3 (A) shows the substrate M in which the front portion removes the front portion. The substrate M is a brittle material substrate such as glass, and has a product portion 1 and a binder portion 2 that distinguishes between the boundary scribing line S. The binder portion 2 is a trapezoidal shape of the rear portion to a narrower, and is formed on the edge 1a of the substrate M. figure 1 The product portion 1 removed after the binding portion 2 is shown, and the trapezoidal shape of the trapezoidal shape having a narrow width of the rear portion is formed by removing the edge portion 2. In the present embodiment, the length H of the trapezoidal shape is set to 50 mm, and the top length L is set to 50 mm, and the tilt angle α of the side is 102 °, so that the corner portion R1 and the ...

no. 2 approach

[0055] Hereinafter, a method of removing the boundary portion of the second embodiment of the present invention will be described in detail with reference to the accompanying drawings. In addition, the same components as those in the first embodiment are marked and the description thereof will be omitted.

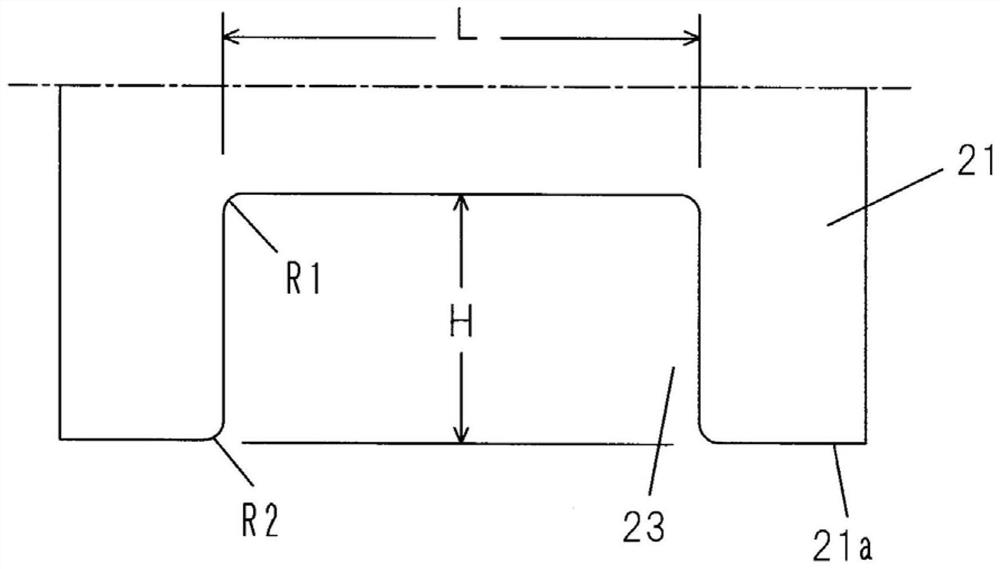

[0056] Figure 7 (A) shows the substrate M1 before the side material is removed. The substrate M1 is constituted by a brittle material substrate such as glass, and has a product portion 21 and a binder portion 22 divided by the boundary scribing line S1. The bound portion 22 is a "コ" shape of one end opening, and is formed on the edge 21a of the substrate M1. The left and right edges of the "コ" glyph are parallel. figure 2 The product portion 21 removing the binder portion 22 is shown to form a "コ" shaped recess 23 by removing the binder portion 22. In the present embodiment, the length H of the depressed portion 23 is set to 60 mm, and the bottom edge length L is set to 120 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com