Temperature sensor

A temperature sensor and sensor technology, applied in thermometers, thermometer parts, instruments, etc., can solve the problems of decreased responsiveness, increased heat capacity and contact area, and achieve improved responsiveness, small heat capacity, and high responsiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

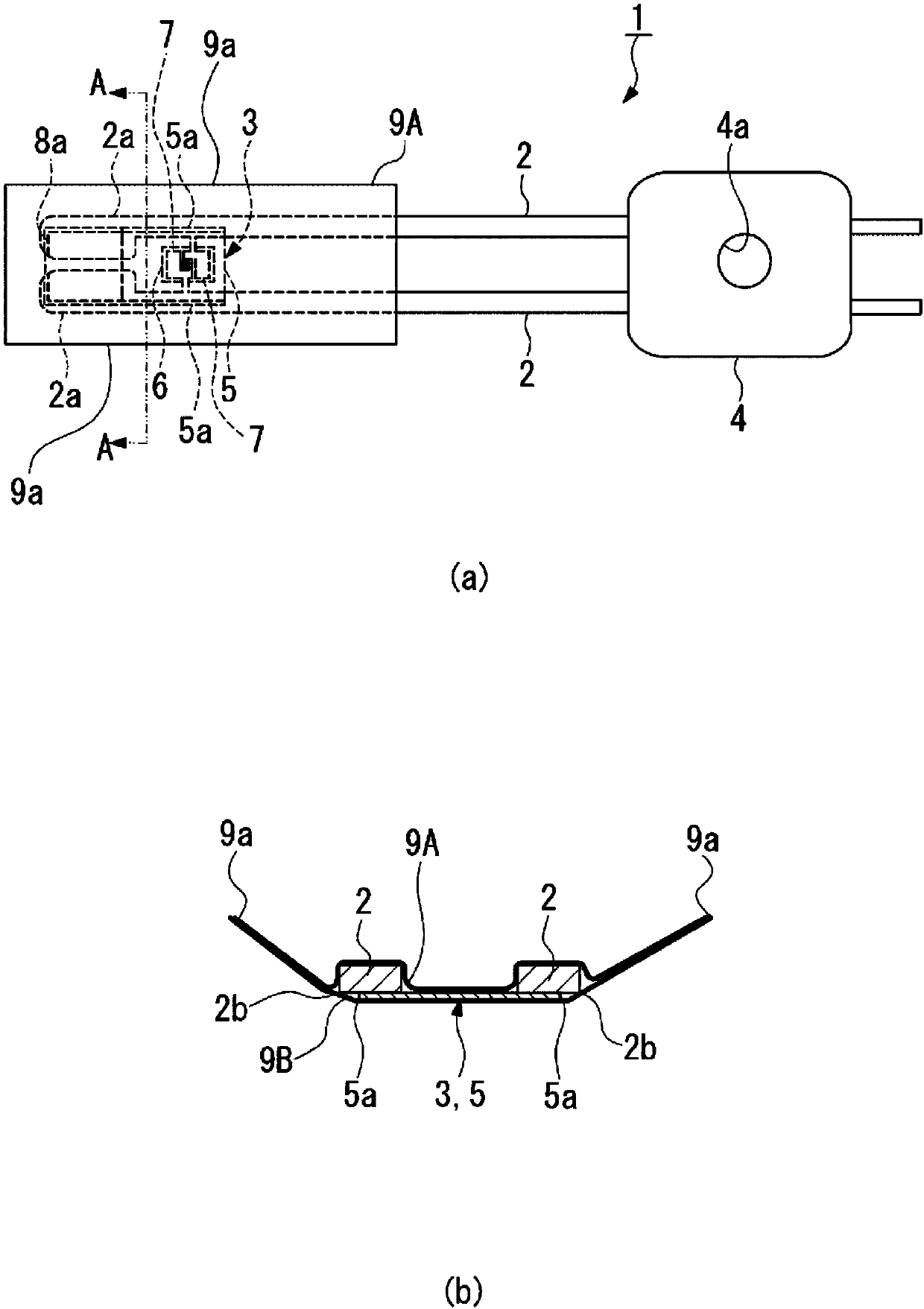

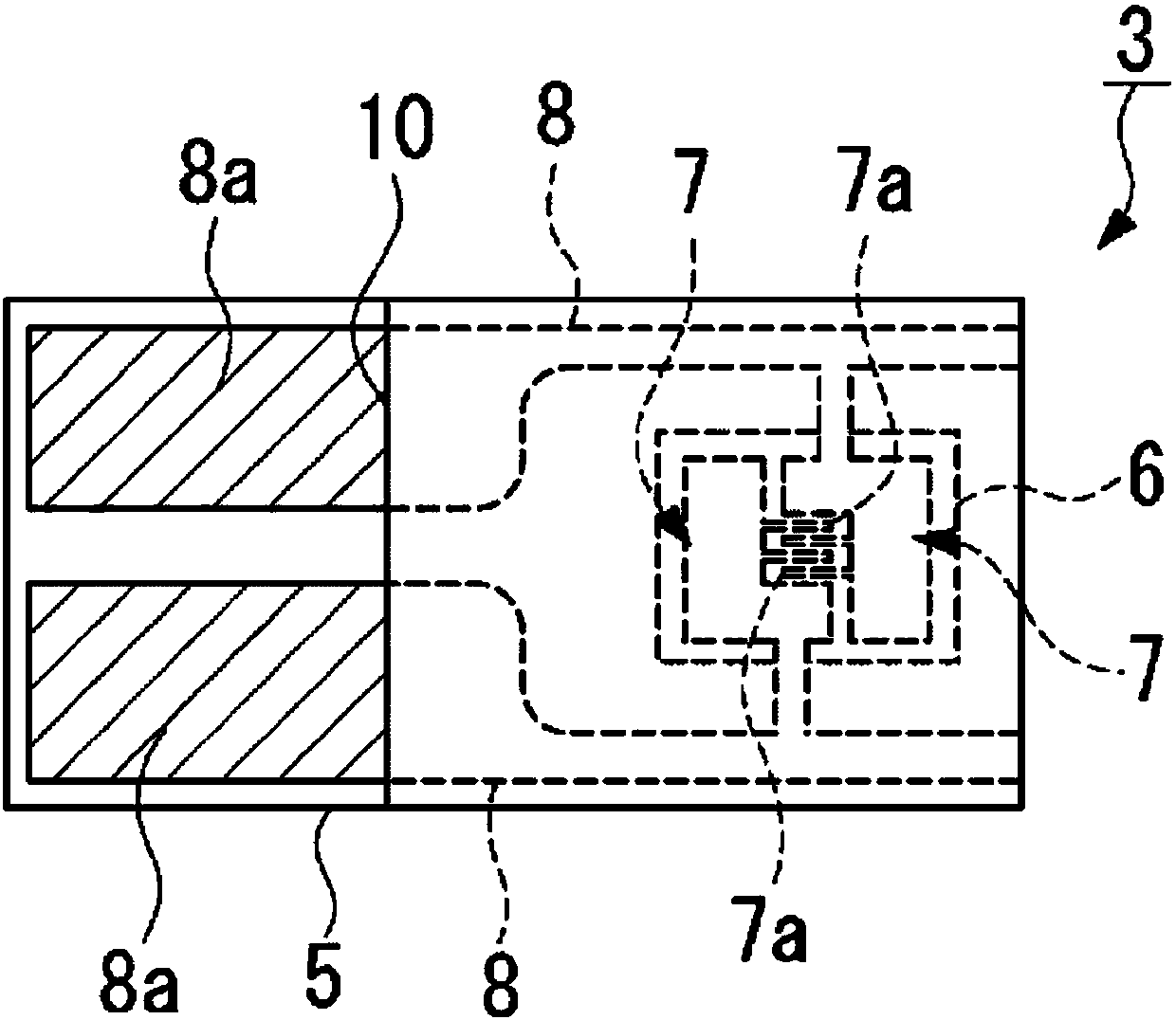

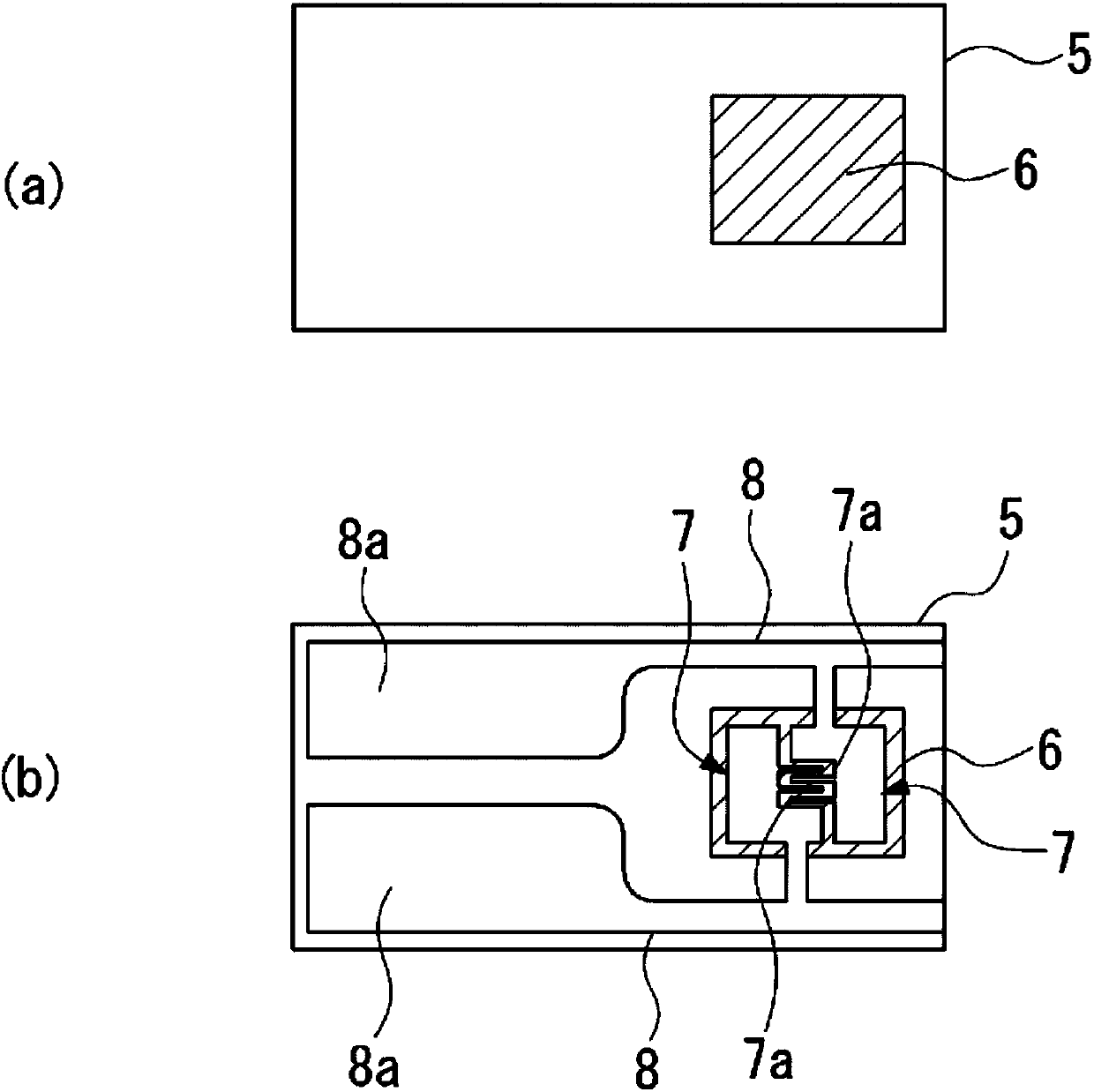

[0027] Below, refer to Figure 1 to Figure 4 One embodiment of the temperature sensor of the present invention will be described. In addition, in a part of the drawings used in the following description, the scale is appropriately changed as necessary in order to make each part recognizable or easily recognizable.

[0028] like figure 1 As shown, the temperature sensor 1 of this embodiment includes a pair of lead frames 2, a sensor part 3 connected to the pair of lead frames 2, and a holding part 4 fixed to the pair of lead frames 2 to hold the pair of lead frames 2 insulated. .

[0029] The sensor unit 3 includes an insulating film 5 on which a pair of lead frames 2 are adhered on the upper surface, a thin film thermistor unit 6 pattern-formed on the upper surface of the insulating film 5 from a thermistor material, A pair of comb electrodes 7 having a plurality of comb portions 7a and patterned to face each other on the resistance portion 6 is connected to the pair of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com