Nitrogen-doped silicon oxide negative electrode material as well as preparation method and application thereof

A technology of silicon oxide and negative electrode materials, which is applied in the direction of battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of low initial charge and discharge efficiency, poor cycle life, etc., and achieve structural stability and high capacity retention. Effects of small negative electrode resistance, improved structural stability and capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

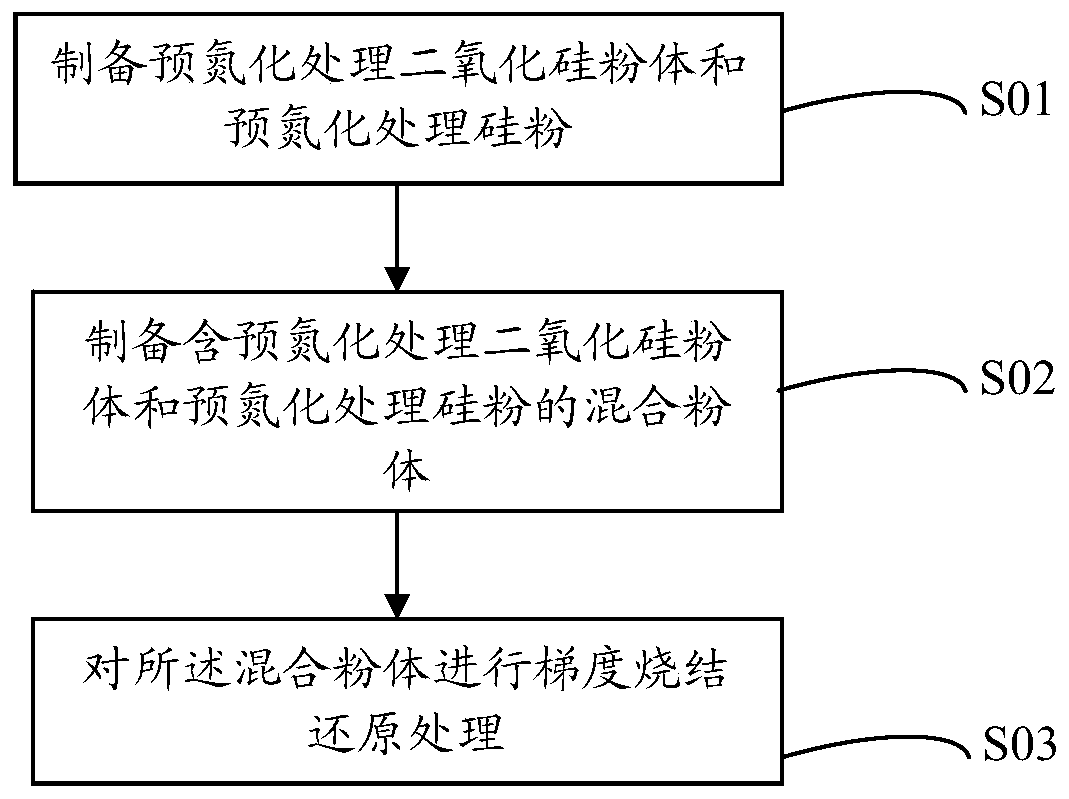

[0021] On the one hand, an embodiment of the present invention provides a method for preparing a nitrogen-doped silicon oxide negative electrode material. The preparation method of the nitrogen-doped silicon oxide negative electrode material comprises the following steps:

[0022] Step S01. Preparing pre-nitrided silicon dioxide powder and pre-nitrided silicon powder: performing a first gradient sintering reduction treatment on the silicon powder and silicon dioxide powder in a first reducing atmosphere containing a nitrogen source, Obtain pre-nitrided silicon dioxide powder and pre-nitrided silicon powder;

[0023] Step S02. Prepare a mixed powder containing pre-nitrided silicon dioxide powder and pre-nitrided silicon powder: combine the pre-nitrided silicon dioxide powder, pre-nitrided silicon powder and organic nitrogen The source is mixed and ball milled to obtain a mixed powder;

[0024] Step S03. Perform gradient sintering reduction treatment on the mixed powder: perfo...

Embodiment 1

[0045] Embodiment 1 provides a nitrogen-doped silicon oxide negative electrode material and a preparation method thereof. The nitrogen-doped silicon oxide negative electrode material is prepared according to a method comprising the following steps:

[0046] S11: Put the nano-scale silicon powder and silicon dioxide powder into the tube furnace respectively, and then pass it into the argon atmosphere with a gas flow rate of 120 sccm; raise the temperature to 400°C at a rate of 8°C per minute, and then put the argon gas into the furnace. The atmosphere was switched to ammonia atmosphere, the gas flow rate was 100 sccm; the temperature was raised to 600°C at a rate of 5°C per minute, and then to 750°C at a rate of 3°C per minute, kept for 1 hour, then switched to an argon atmosphere, and then cool down;

[0047] S12: Mix and grind the pre-nitrided silica powder and silicon powder obtained in step S11 at a molar ratio of 1:1, and add the mass of the pre-nitrided silica powder aft...

Embodiment 2

[0050] Embodiment 1 provides a nitrogen-doped silicon oxide negative electrode material and a preparation method thereof. The nitrogen-doped silicon oxide negative electrode material is prepared according to a method comprising the following steps:

[0051] S11: Put the nano-scale silicon powder and silicon dioxide powder into the tube furnace respectively, and then pass it into the argon atmosphere with a gas flow rate of 120 sccm; raise the temperature to 400°C at a rate of 8°C per minute, and then put the argon gas into the furnace. The atmosphere is switched to ammonia atmosphere, the gas flow rate is 100sccm; the temperature is raised to 600°C at a rate of 5°C per minute, and then to 750°C at a rate of 3°C per minute, kept for 1 hour, then switched to an argon atmosphere, and then cool down;

[0052] S12: Mix and grind the pre-nitrided silicon dioxide powder and silicon powder obtained in step S11 according to a molar ratio of 0.9:1, and add the mass of the pre-nitrided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com