Preparation method of trilobal polylactic acid pattern fiber

A technology of polylactic acid and trilobal type, which is applied in fiber processing, stretch spinning, filament forming processing, etc., can solve the problems of limited fluffy effect of single curl, unsatisfactory elasticity, monotonous color and other problems, and meet the requirements of industrialization The effect of amplifying production requirements and short process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

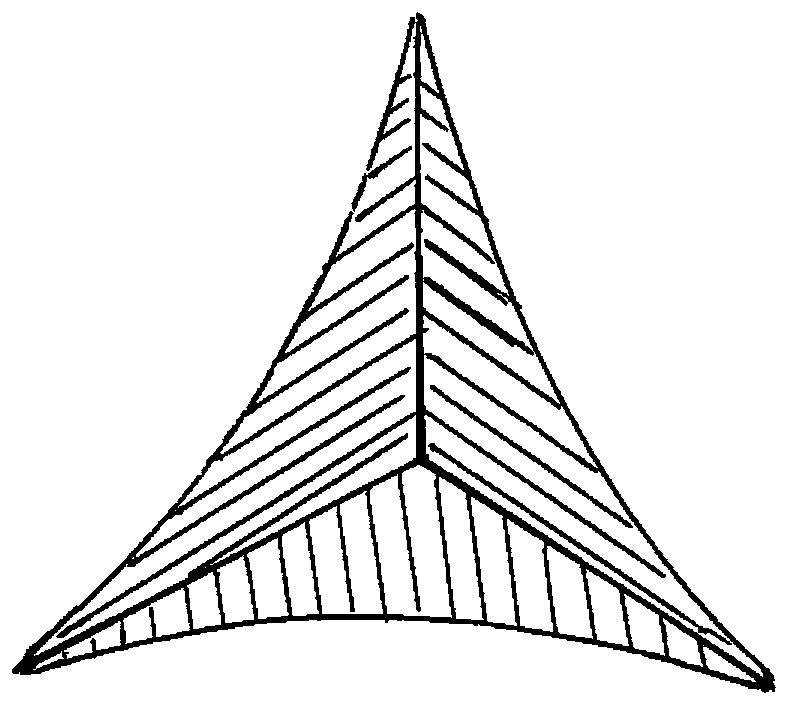

[0022] figure 1 The preparation method of shown trilobal polylactic acid color fiber comprises the following steps:

[0023] A) Raw material preparation, prepare polylactic acid slices I with the first intrinsic viscosity, polylactic acid slices II with the second intrinsic viscosity, and polylactic acid slices III with the third intrinsic viscosity and dry them separately. In this step, the The polylactic acid slice I with the first intrinsic viscosity, the polylactic acid slice II with the second intrinsic viscosity, and the polylactic acid slice III with the third intrinsic viscosity have a volume ratio of 1:1:1, and the first intrinsic viscosity The viscosity value of the polylactic acid slice I is 0.8 dL / g, the viscosity value of the second intrinsic viscosity is 1dL / g, the viscosity value of the third intrinsic viscosity is 1.2 dL / g, and the drying temperature for drying the polylactic acid slice I is The temperature is 70°C, the drying time is 18h, the drying temperatu...

Embodiment 2

[0027] figure 1 The preparation method of shown trilobal polylactic acid color fiber comprises the following steps:

[0028] A) Raw material preparation, prepare polylactic acid slices I with the first intrinsic viscosity, polylactic acid slices II with the second intrinsic viscosity, and polylactic acid slices III with the third intrinsic viscosity and dry them separately. In this step, the The volume ratio of the polylactic acid slice I with the first intrinsic viscosity, the polylactic acid slice II with the second intrinsic viscosity, and the polylactic acid slice III with the third intrinsic viscosity is 1:0.9:0.95, and the first intrinsic viscosity The viscosity value of the second intrinsic viscosity is 0.6 dL / g, the viscosity value of the second intrinsic viscosity is 0.8dL / g, the viscosity value of the third intrinsic viscosity is 1dL / g, and the drying temperature for drying the polylactic acid slice I is The drying temperature for drying the polylactic acid slice II...

Embodiment 3

[0032] figure 1 The preparation method of shown trilobal polylactic acid color fiber comprises the following steps:

[0033] A) Raw material preparation, prepare polylactic acid slices I with the first intrinsic viscosity, polylactic acid slices II with the second intrinsic viscosity, and polylactic acid slices III with the third intrinsic viscosity and dry them separately. In this step, the The volume ratio of the polylactic acid slice I with the first intrinsic viscosity, the polylactic acid slice II with the second intrinsic viscosity, and the polylactic acid slice III with the third intrinsic viscosity is 1:0.95:0.9, and the first intrinsic viscosity The viscosity value of the polylactic acid slice I is 0.7 dL / g, the viscosity value of the second intrinsic viscosity is 0.9 dL / g, and the viscosity value of the third intrinsic viscosity is 1.1 dL / g. Dry the polylactic acid slice I The temperature is 80°C, the drying time is 12h, the drying temperature for drying the polylac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com