Special water-based ink for polyethylene-polyvinyl acetate thin films and preparation method of ink

A technology of water-based ink and polyvinyl ester, which is applied in ink, applications, household appliances, etc., and can solve problems such as false drying of printed matter, affecting printing production efficiency, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

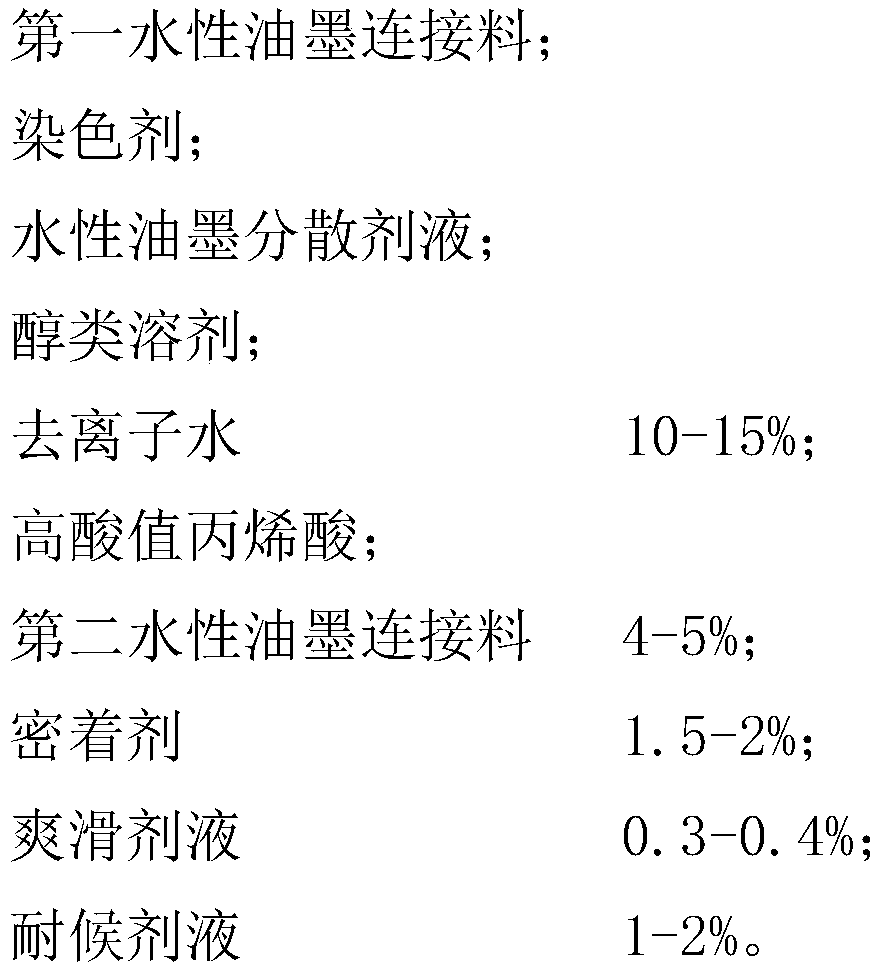

Examples

Embodiment 1

[0093] A. Water-based ink binder (high molecular weight resin, hydrophilic value: 10-12) content: 20%

[0094] B. Rutile titanium dioxide content: 28%

[0095] C. Water-based ink dispersant liquid content: 1%

[0096] D. Alcohol solvent content: 25%

[0097] E. Deionized water content: 11.7%

[0098] F. High acid value acrylic acid content: 6%

[0099] G. Water-based ink binder (low molecular weight resin, hydrophilic value: 11-13) content: 5%

[0100] H. Adhesive content: 1.5%

[0101] J. Smoothing agent liquid content: 0.3%

[0102] K, weathering agent liquid content: 1.5%

[0103] White ink preparation includes the following steps:

[0104](1) Pre-dispersion of ingredients: According to the production process sheet, clean the special production material tank, and after checking the item number is correct, put part D alcohol solvent, part E deionized water in turn, after stirring and mixing evenly, put A water-based Ink binder (high molecular weight resin, hydrophili...

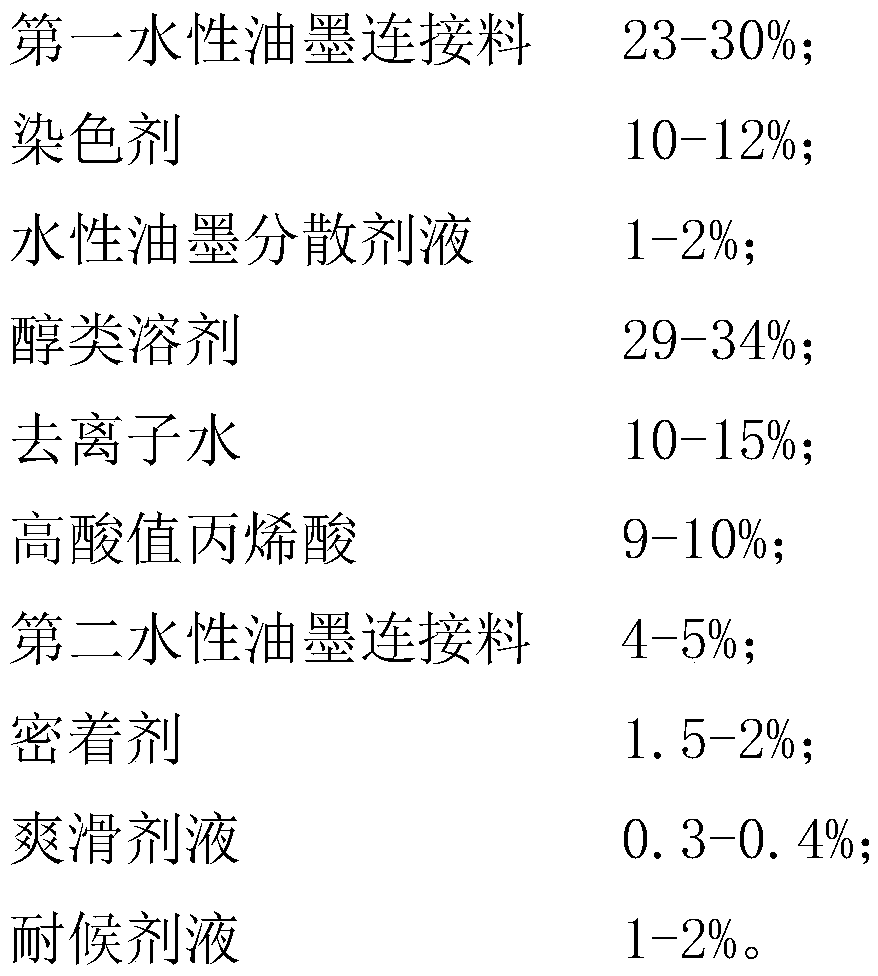

Embodiment 2

[0108] A. Water-based ink binder (high molecular weight resin, hydrophilic value: 10-12) content: 20%

[0109] B. Rutile titanium dioxide content: 29%

[0110] C. Water-based ink dispersant liquid content: 1%

[0111] D. Alcohol solvent content: 24%

[0112] E. Deionized water content: 11.7%

[0113] F. High acid value acrylic acid content: 6%

[0114] G. Water-based ink binder (low molecular weight resin, hydrophilic value: 11-13) content: 5%

[0115] H. Adhesive content: 1.5%

[0116] J. Smoothing agent liquid content: 0.3%

[0117] K, weathering agent liquid content: 1.5%

[0118] (1) Pre-dispersion of ingredients: According to the production process sheet, clean the special production material tank, and after checking the item number is correct, put part D alcohol solvent, part E deionized water in turn, after stirring and mixing evenly, put A water-based Ink binder (high molecular weight resin, hydrophilic value: 10-12). Adjust the speed of the disperser to 300-40...

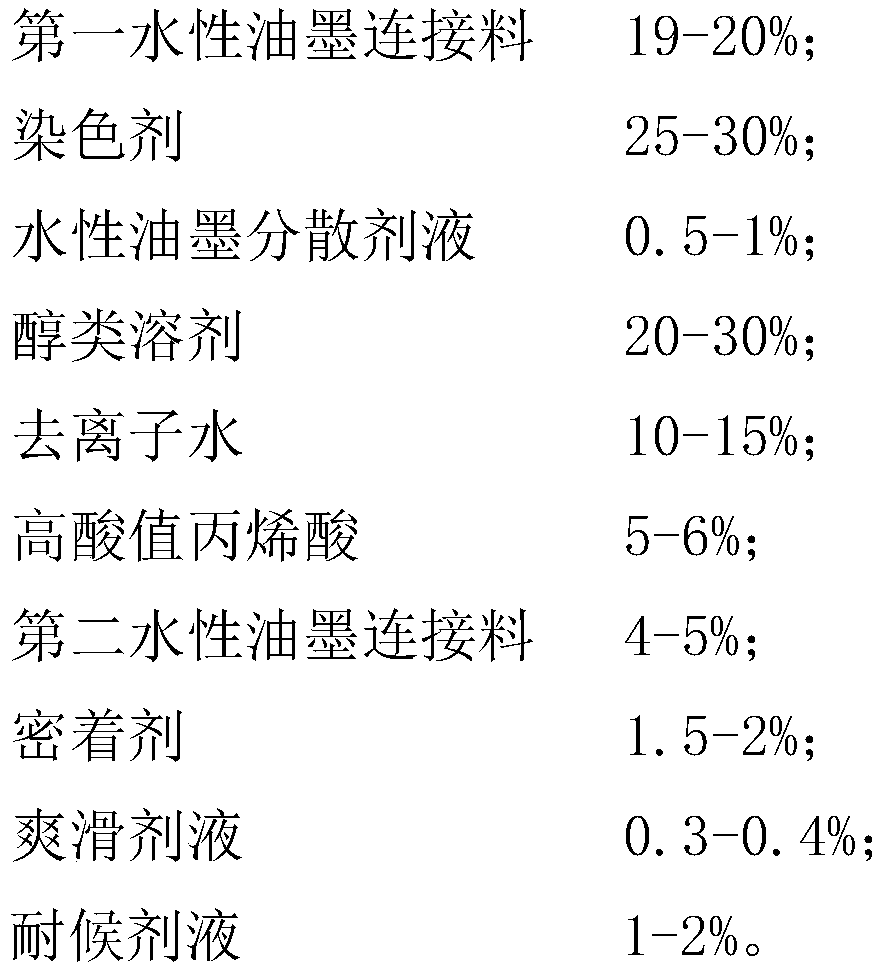

Embodiment 3

[0122] A. Water-based ink binder (high molecular weight resin, hydrophilic value: 10-12) content: 19%

[0123] B. Rutile titanium dioxide content: 30%

[0124] C. Water-based ink dispersant liquid content: 1%

[0125] D. Alcohol solvent content: 24%

[0126] E. Deionized water content: 11.7%

[0127] F. High acid value acrylic acid content: 6%

[0128] G. Water-based ink binder (low molecular weight resin, hydrophilic value: 11-13) content: 5%

[0129] H. Adhesive content: 1.5%

[0130] J. Smoothing agent liquid content: 0.3%

[0131] K, weathering agent liquid content: 1.5%

[0132] (1) Pre-dispersion of ingredients: According to the production process sheet, clean the special production material tank, and after checking the item number is correct, put part D alcohol solvent, part E deionized water in turn, after stirring and mixing evenly, put A water-based Ink binder (high molecular weight resin, hydrophilic value: 10-12). Adjust the speed of the disperser to 300-40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com