Oxidation-reduction potential precise control method and system for reverse osmosis device

A reverse osmosis device and precise control technology, applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, water/sewage treatment, etc., can solve problems such as change and ORP control, and achieve increased stability and excellent working conditions , the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

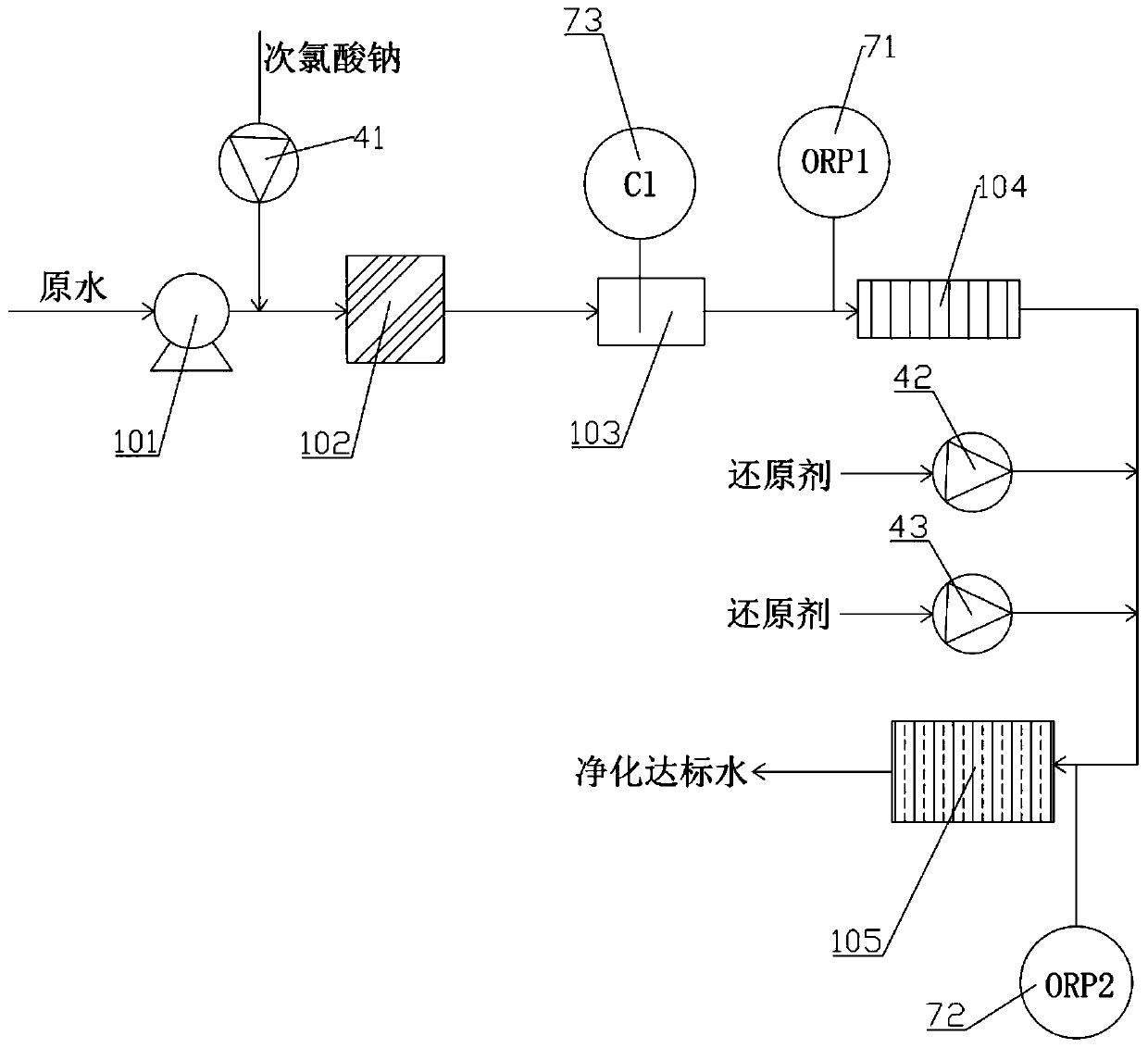

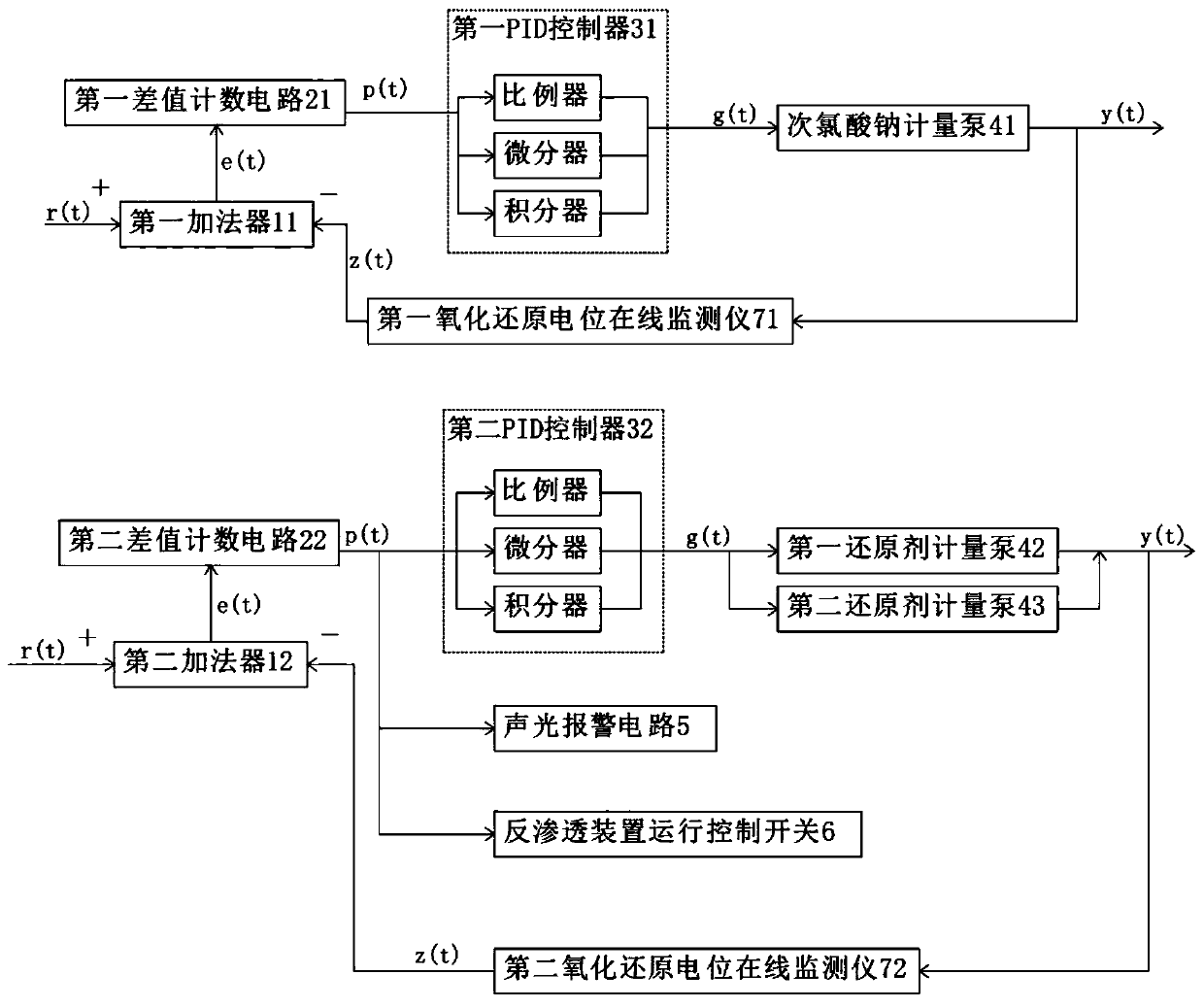

[0050] A method for precisely controlling the oxidation-reduction potential of a reverse osmosis device, comprising the steps of:

[0051] S1. Set the first online oxidation-reduction potential measuring instrument at the inlet of the multimedia filter of the reverse osmosis system, and set the sodium hypochlorite metering pump at the outlet of the booster pump. By controlling the frequency or opening of the sodium hypochlorite metering pump, the multimedia filter The ORP at the inlet is controlled at 500-600mV;

[0052] S2. Install a second online redox potential measuring instrument at the inlet of the reverse osmosis device of the reverse osmosis system, and use the values measured by the second online redox potential measuring instrument as the first reducing agent metering pump and the second reducing agent metering pump The control parameters of the frequency or opening degree are as follows:

[0053] S21. When the ORP at the inlet of the reverse osmosis device is les...

Embodiment 2

[0059] A method for precisely controlling the oxidation-reduction potential of a reverse osmosis device, comprising the steps of:

[0060] S1. Set the first online oxidation-reduction potential measuring instrument at the inlet of the multimedia filter of the reverse osmosis system, and set the sodium hypochlorite metering pump at the outlet of the booster pump. By controlling the frequency or opening of the sodium hypochlorite metering pump, the multimedia filter The ORP at the inlet is controlled at 500-600mV;

[0061] Control the ORP at the inlet of the multi-media filter at 500-600mV, which can not only avoid the growth of organic matter and microorganisms at the inlet and inside of the multi-media filter, but also prevent the oxidation damage of the multi-media filter and ensure a good pre-treatment desalination effect.

[0062] . Install a second online redox potential detector at the inlet of the reverse osmosis device of the reverse osmosis system, and use the values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com