An air-injection quartz sand hydraulic separation method

A technology of hydraulic separation and quartz sand, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc. To meet the standards and other issues, to achieve the effect of shortening the production process and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

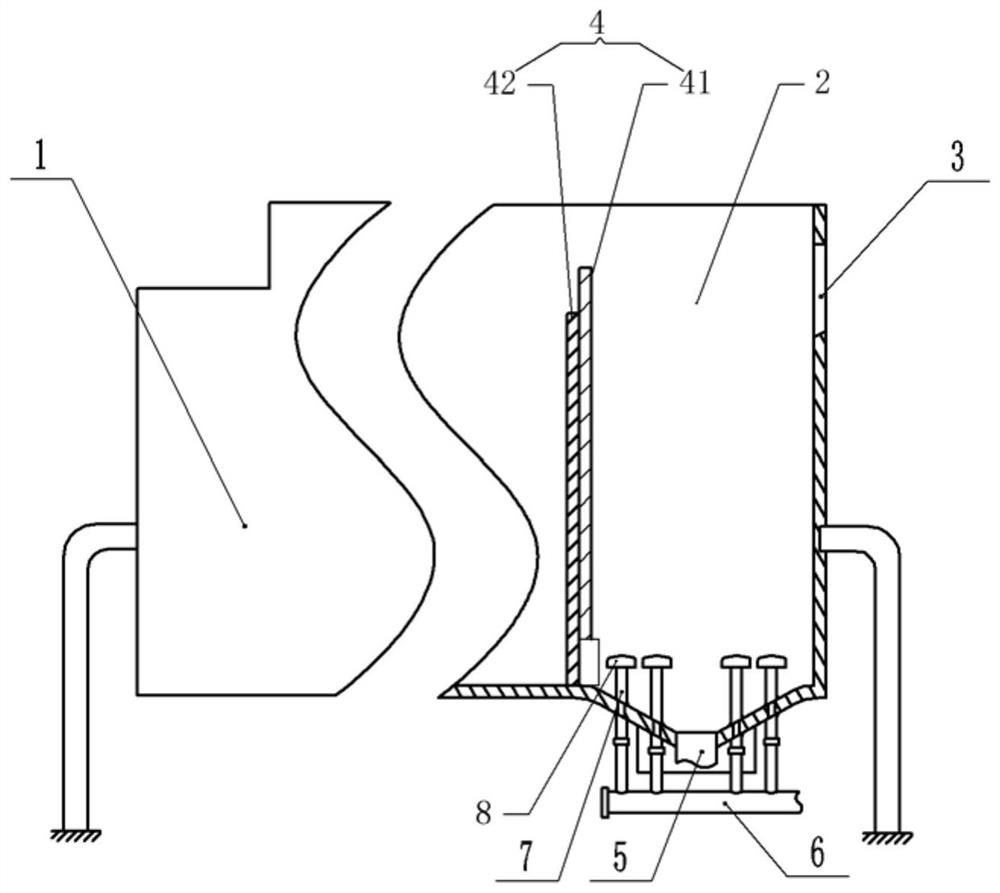

Image

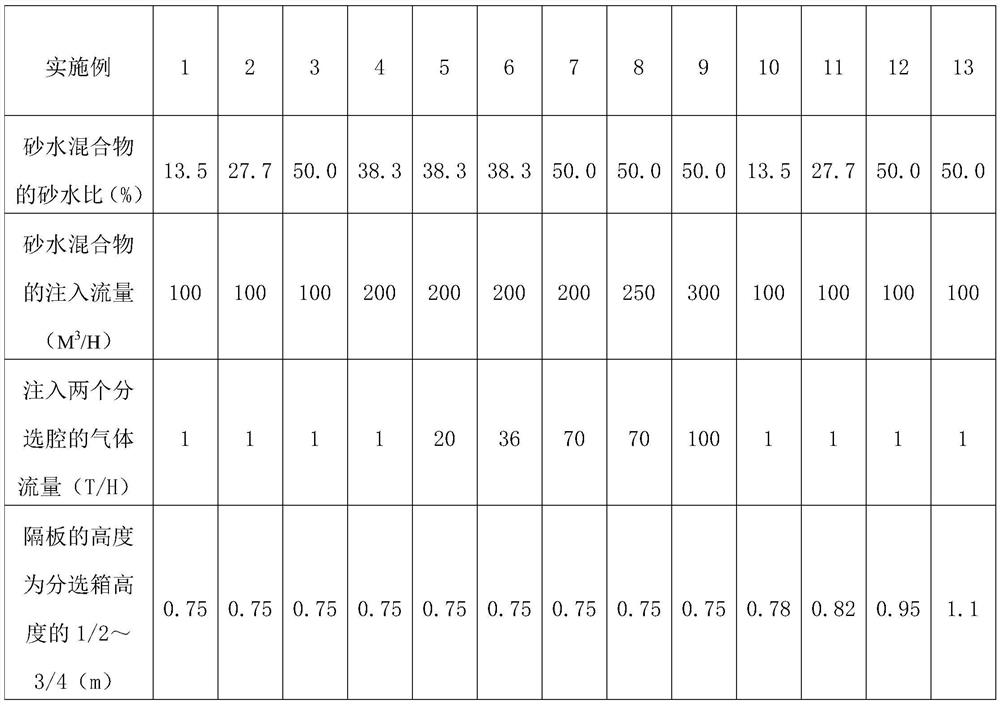

Examples

Embodiment 7

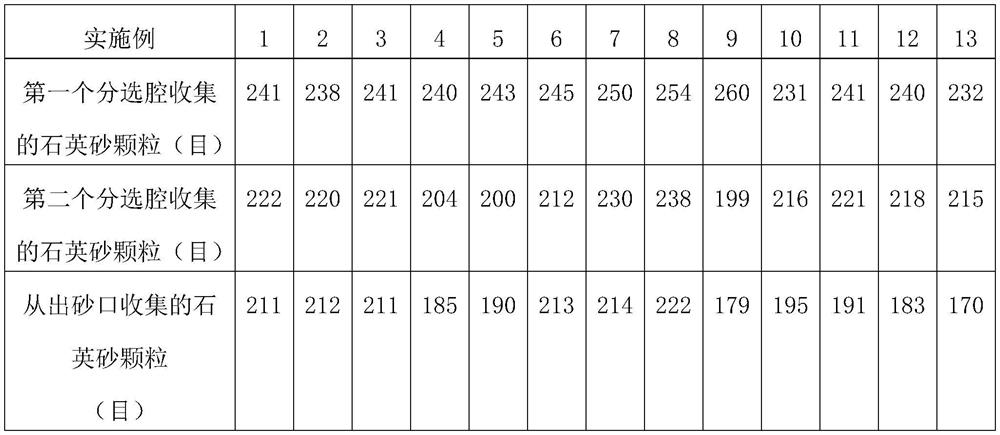

[0045] In Embodiment 7 and Embodiment 8, the injection flow rate of the sand-water mixture is changed, that is, the component force in the horizontal direction is increased, the horizontal component force increases, and the quartz sand particles at the sand outlet gradually increase, and the horizontal component force affects the outlet. The particle size of the quartz sand in the sand port has a greater influence.

Embodiment 8

[0046] In Examples 8 and 9, the injection rate of the sand-water mixture increases, the flow rate of the gas increases, and the particle size of the quartz sand particles in the sorting box 1 and the sand outlet increases. In summary, the sorting of quartz sand particles is affected by the horizontal component force (injection flow rate of the sand-water mixture) and the vertical component force (gas flow rate injected into the sorting box 1).

[0047] In Example 10 to Example 13, the height of the dividing plate was gradually increased, that is, the resistance of the horizontal component force (injection flow rate of the sand-water mixture) was gradually increased, and the horizontal component force was reduced. The particle size of the quartz sand particles decreases gradually, and the particle size of the quartz sand in the two sorting chambers 2 increases gradually.

[0048] To sum up, when screening quartz sand particles of different sizes, the injection amount of sand-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com