Nige single crystal film with unlimited thickness and its preparation method and application

A single crystal thin film, limited technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems such as the difficulty of preparing single crystal thin films, and achieve good thermal stability, small contact resistance and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

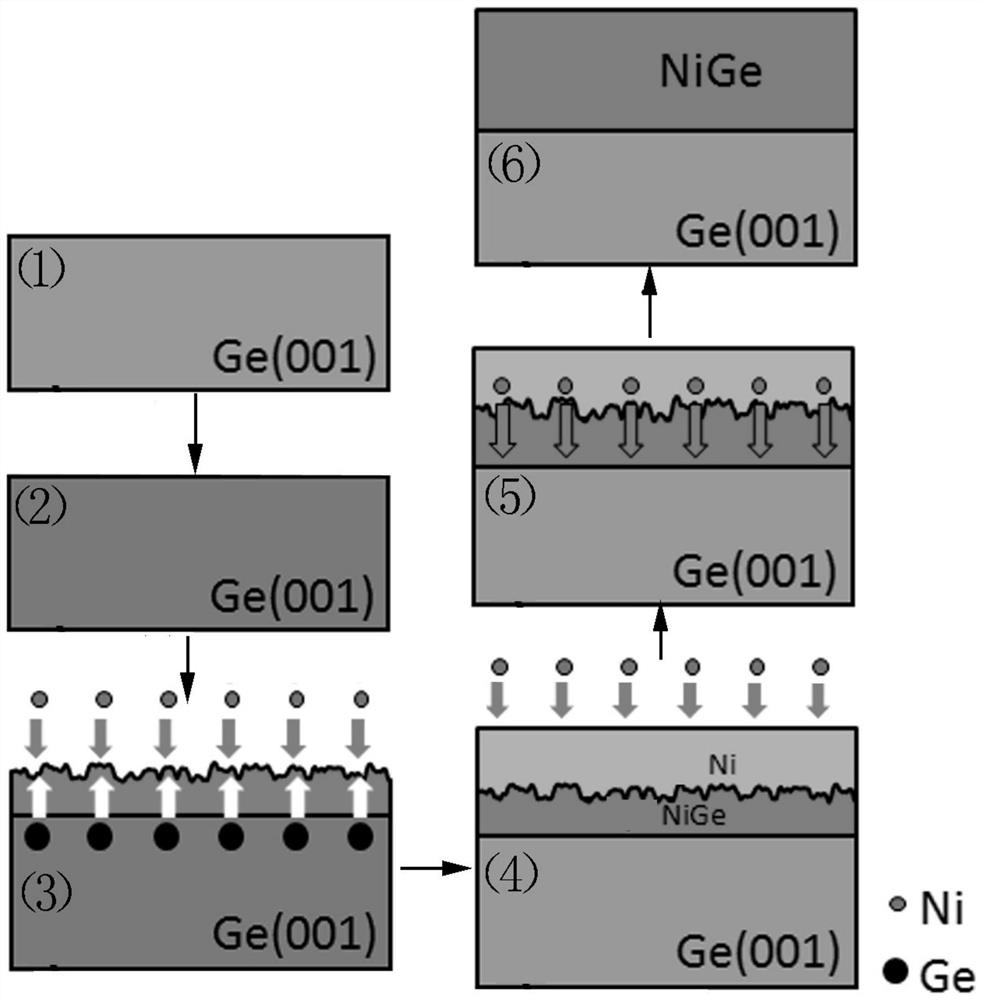

[0025] see figure 1 As shown in the preparation process flow chart, the embodiment of the present invention provides a method for preparing a NiGe single crystal thin film.

[0026] The preparation method comprises the following steps:

[0027] Step S01. Provide a clean Ge(001) substrate, such as figure 1 as shown in (1);

[0028] Step S02. Place the Ge(001) substrate in a vacuum environment for heat treatment, and then cool it down to room temperature to obtain a pre-used substrate, specifically as follows figure 1 as shown in (2);

[0029] Step S03. In a vacuum environment, carry out reactive evaporation treatment of Ni on the surface of the pre-used substrate, so that a layer of NiGe single crystal film is formed on the surface of Ge(001), specifically as follows figure 1 (3)~(4);

[0030] Step S04. At room temperature, vapor-deposit a layer of Ni film on the surface of the NiGe single crystal film, specifically as figure 1 (4)~(5);

[0031] Step S05. Under an inert ...

Embodiment 1

[0060] This embodiment 1 provides a method for preparing a NiGe single crystal thin film, comprising the following steps:

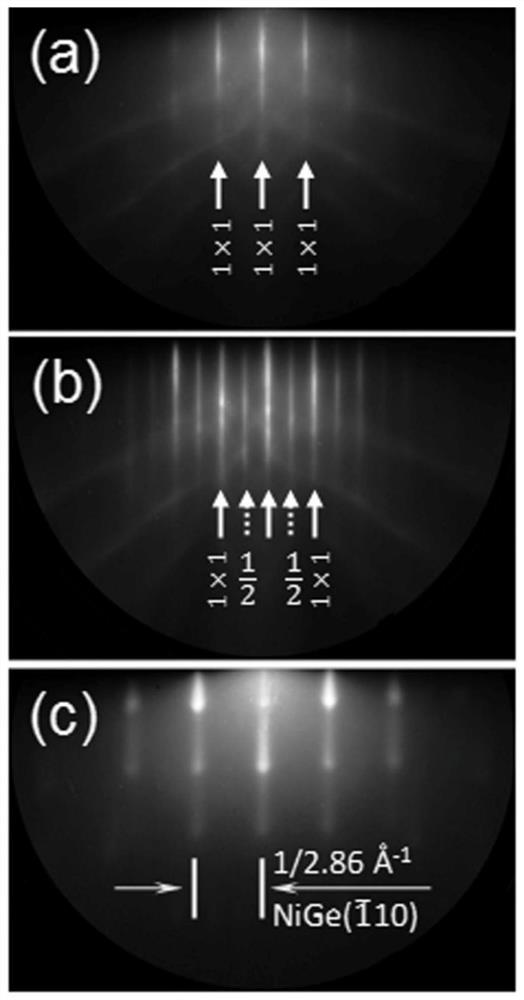

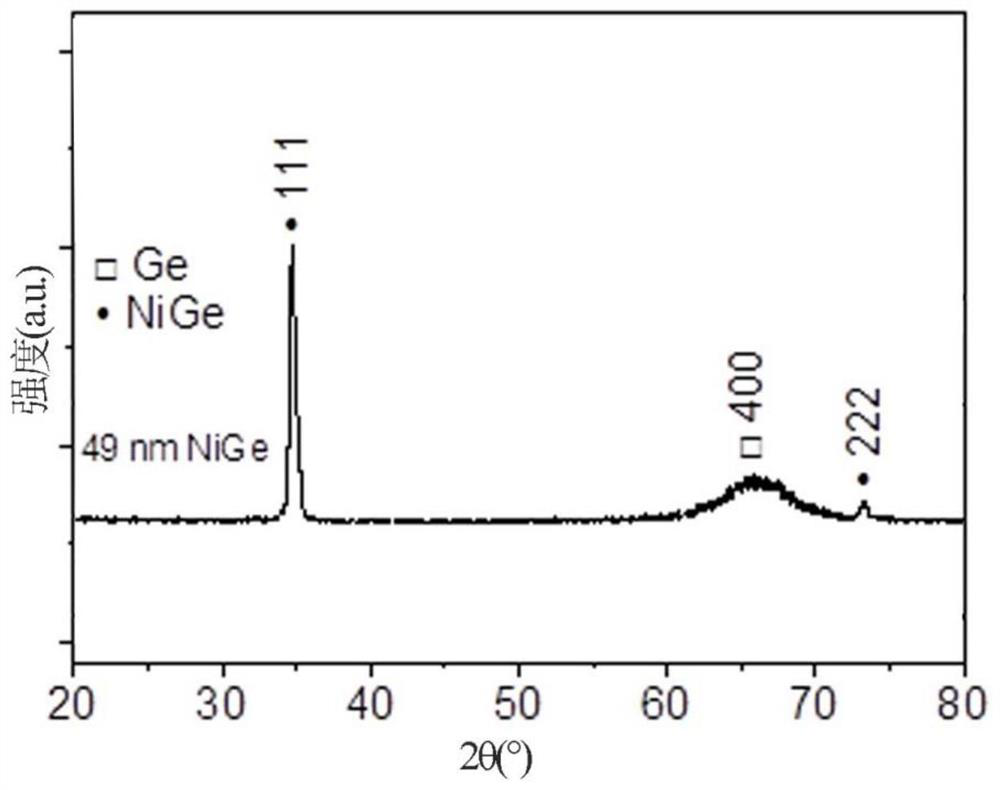

[0061] Step S11. Provide As-doped n-type Ge(001), whose volume resistivity is about 8Ωcm, and use it as a substrate, and perform a reflective high-energy electron diffraction (RHEED) scan on the Ge(001) substrate, and the specific results Such as figure 2 (a) shown.

[0062] Step S12. Cleaning Ge(001). Immerse the Ge(001) substrate in HF solution with a mass concentration of 1% for 1 min; take it out and soak it in flowing deionized water for 1 min, and immerse it in HF solution and deionized water 5 times in a cycle. ; followed by N 2 After drying the deionized water on the Ge(001) substrate with an air gun, immediately send the Ge(001) substrate into a chamber with a vacuum degree higher than 1e-5Pa, heat it to 700°C, keep the temperature constant for 60min, then cool it down to room temperature, and then Scan the RHEED graph, the specific results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com