Composite explosion suppression body based on foam metal filled with ultrafine powder explosion suppressant

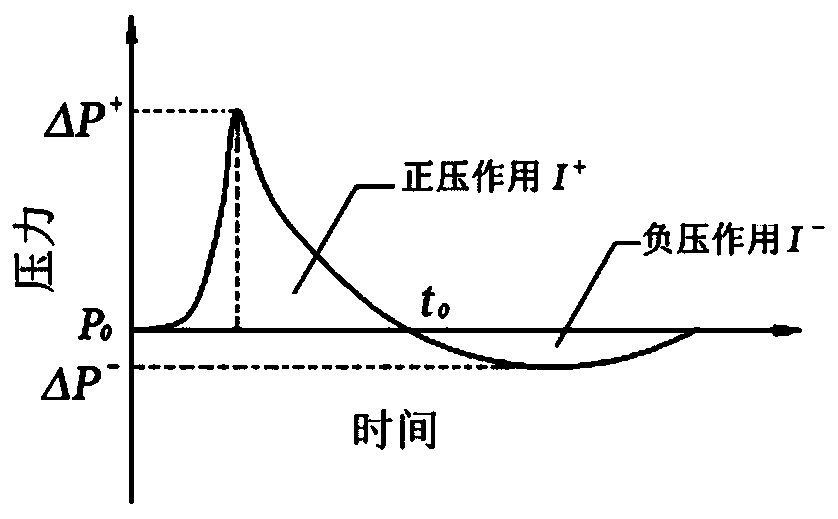

An ultra-fine powder and metal foam technology, which is applied in blasting and other directions, can solve the problems of not comprehensively considering the overall trend of explosion pressure, general explosion-proof flame retardant effect, and large shape and density. It achieves good explosion suppression effect and is beneficial to Stable, effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A composite explosion suppressor based on foam metal filled with an ultrafine powder explosion suppressant is divided into two layers: an overpressure buffer layer 1 and an explosion barrier layer 2 . The overpressure buffer layer 1 and the explosion barrier layer 2 are connected by peripheral welding. The explosion barrier layer 2 is iron-nickel metal foam evenly filled with NaHCO 3 It is composed of ultra-fine powder evenly mixed with rock powder, in which the ratio of iron and nickel content in the iron-nickel foam metal is 9:1, the porosity is 95%, and the density is 1.4g / cm 3 ;NaHCO 3 The particle size of the ultrafine powder and rock powder is 10 μm. Simulate a gas explosion with a 10% methane-air mixture. The volume of iron-nickel metal foam is 500cm 3 , control NaHCO 3 and NaHCO in rock powder ultrafine powder mixture 3 The mass content ratio of rock powder is 1:1, and the filling ratio in iron-nickel foam metal is 30%. The pressure signal is collected by...

Embodiment 2

[0032]A composite explosion suppressor based on foam metal filled with an ultrafine powder explosion suppressant is divided into two layers: an overpressure buffer layer 1 and an explosion barrier layer 2 . The overpressure buffer layer 1 and the explosion barrier layer 2 are connected by peripheral welding. The explosion barrier layer 2 is iron-nickel foam metal filled with NaHCO evenly 3 It is composed of ultra-fine powder evenly mixed with rock powder, in which the ratio of iron and nickel content in the iron-nickel foam metal is 9:1, the porosity is 95%, and the density is 1.4g / cm 3 ;NaHCO 3 The particle size of the ultrafine powder and rock powder is 10 μm. Simulate a gas explosion with a 10% methane-air mixture. The volume of iron-nickel metal foam is 500cm 3 , control NaHCO 3 and NaHCO in rock powder ultrafine powder mixture 3 The mass content ratio of rock powder is 2:1, and the filling ratio in iron-nickel foam metal is 30%. The pressure signal is collected by ...

Embodiment 3

[0034] A composite explosion suppressor based on foam metal filled with an ultrafine powder explosion suppressant is divided into two layers: an overpressure buffer layer 1 and an explosion barrier layer 2 . The overpressure buffer layer 1 and the explosion barrier layer 2 are connected by peripheral welding. The explosion barrier layer 2 is iron-nickel foam metal filled with NaHCO evenly 3 It is composed of ultra-fine powder evenly mixed with rock powder, in which the ratio of iron and nickel content in the iron-nickel foam metal is 9:1, the porosity is 95%, and the density is 1.4g / cm 3 ;NaHCO 3 The particle size of the ultrafine powder and rock powder is 10 μm. Simulate a gas explosion with a 10% methane-air mixture. The volume of iron-nickel metal foam is 500cm 3 , control NaHCO 3 and NaHCO in rock powder ultrafine powder mixture 3 The mass content ratio of rock powder is 1:2, and the filling ratio in iron-nickel foam metal is 30%. The pressure signal is collected by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com