Molten iron KR desulfurization mixer bonded slag quick removal method

A cleaning method and agitator technology, which are applied in the field of molten iron pretreatment, can solve the problems of high difficulty in processing process control, difficulty in popularization and application in iron and steel enterprises, and rising material consumption costs, so as to reduce the secondary desulfurization rate of molten iron and the consumption of desulfurizers, The effect of improving production efficiency and technical and economic indicators, and reducing the compactness and bonding strength of sticky slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

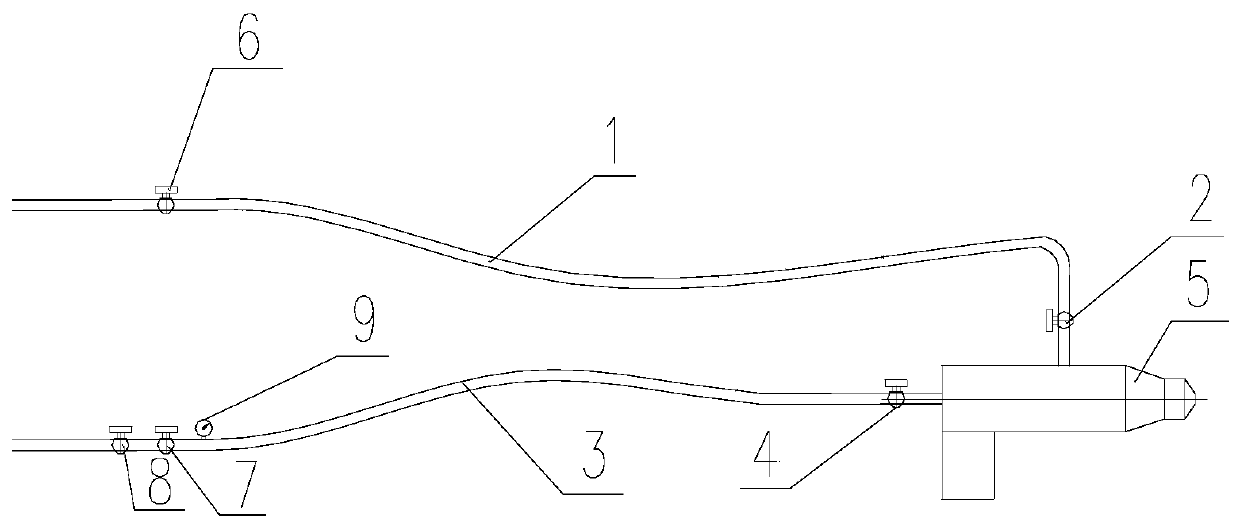

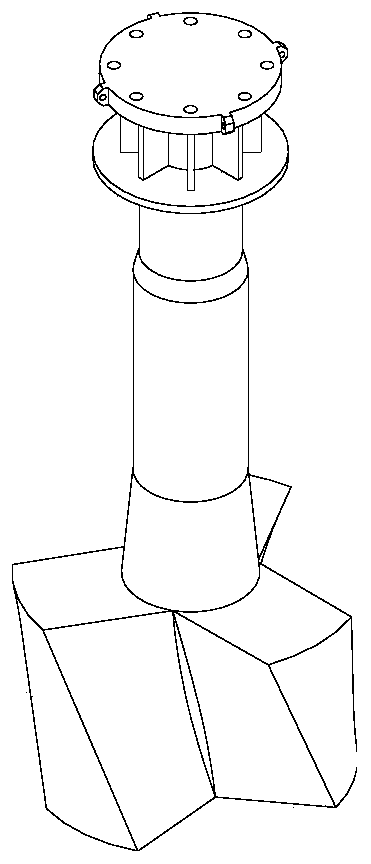

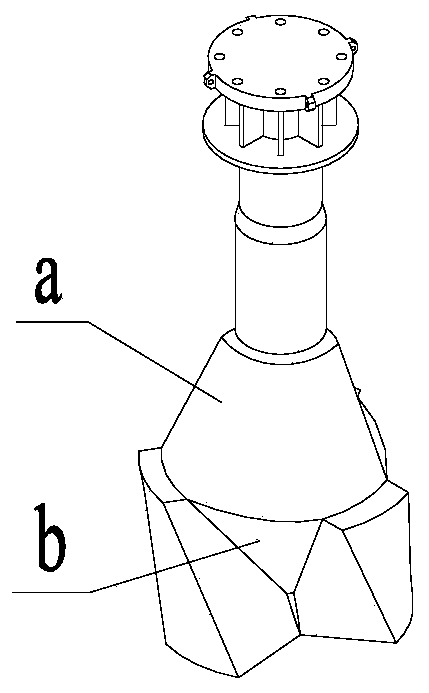

[0042] Quick cleaning method of sticky slag in molten iron KR desulfurization agitator, such as Figure 2-4 As shown, the water mist injection system is first installed on the operating platform of the 200t hot metal tank KR stirring desulfurization station in a steel factory. The water mist injection system includes tap water connection hose 1, tap water control valve 2, high-pressure air connection hose 3, high-pressure Air control valve 4, high-pressure water mist spray gun 5, tap water shut-off valve 6, high-pressure air pressure reducing valve 7, high-pressure air shut-off valve 8 and high-pressure air pressure gauge 9, wherein tap water connection hose 1, tap water control valve 2 and high-pressure water The fog spray gun 5 is connected to the tap water interface 5.1 to form a water supply channel, and is connected to the tap water pipeline in the factory building through the tap water cut-off valve 6; the high-pressure air connection hose 3, the high-pressure control air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com