Direct injection type hot metal desulfurization spray gun

A direct technology for hot metal desulfurization, applied in the field of hot metal pretreatment, can solve the problems that the desulfurization effect of lime powder is not fully exerted, it is difficult to further improve the utilization efficiency of desulfurizer, and the consumption of desulfurizer is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

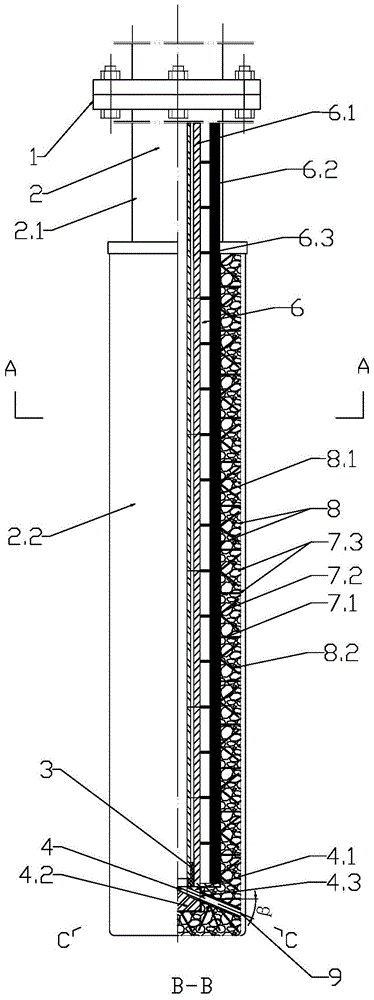

[0056] like figure 1 , 4 , 5, 6, 7, 8, 9, and 10, a molten iron desulfurization spray gun for direct injection of metal particle magnesium, including a connecting flange 1 and a gun barrel connected in sequence, and the gun barrel 2 is connected by a connecting section The gun barrel 2.1 and the gun body section gun barrel 2.2 are composed, the connecting section gun barrel 2.1 includes the gun core 6, the gun body section gun barrel 2.2 includes the gun core 6, the anchor piece group 7 and the refractory castable lining 8, and the gun core 6 is sequentially arranged from inside to outside Both are the main pipe 6.1 and the reinforcing pipe 6.2. The outside of the main pipe 6.1 takes the axis as the center line and evenly arranges a plurality of bridging weldments 6.3 for connecting the reinforcing pipe 6.2, and the lower end of the gun core 6 of the gun barrel 2.2. It is connected with a distributor 4 for distributing metal particle magnesium, magnesium-based or calcium-base...

Embodiment 2

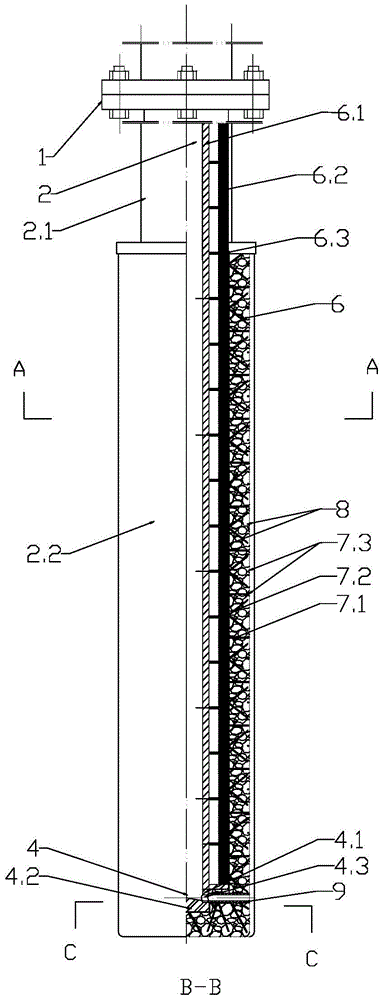

[0072] as attached figure 2 , 5 , 6, 7, 8, 9 and 10 show: a kind of molten iron desulfurization spray gun for direct injection of metal particle magnesium, magnesium-based or calcium-based desulfurizer, this embodiment is basically the same as embodiment 1, the difference is that :

[0073] In the composition of the spray gun, there is no injection pipe 5 and the interface 3 of the injection pipe. The connecting short pipe 4.1 is welded and communicated with the main pipe 6.1, and the inner and outer diameters of the short connecting pipe 4.1 are the same as those of the main pipe 6.1.

[0074] How to use the spray gun:

[0075] The spray gun is directly used for desulfurization, and the insertion depth of the spray gun is controlled so that the outlet of the spray pipe 9 is 250-350 mm away from the bottom of the tank. According to the number of spray gun injection pipes 9 and the total area of the injection port, the pressure and flow of the injection carrier gas are co...

Embodiment 3

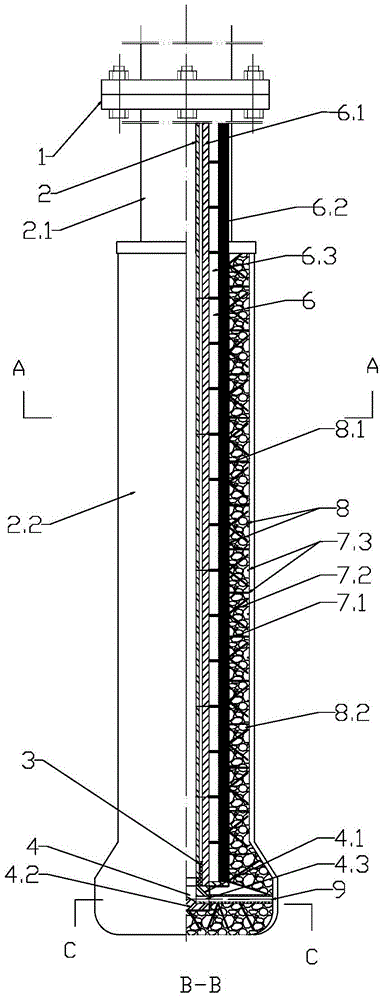

[0077] as attached image 3 , 4 , 5, 6, 7, 8, 9 and 10, the difference between this embodiment and embodiment 1 and embodiment 2 is that the gun body at the gun head where the distributor 4 and the spray pipe 9 are located is a thickened gun body , the junction of the bottom surface and the side of the gun head is a circular arc transition surface, and the bevel transition between the thickened gun body and the non-thickened gun body. Other structures and using method are identical with embodiment 1, embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com