Pigment dispersion liquid preparation method

A pigment dispersion and pigment technology, applied in the field of pigment dispersion preparation, can solve the problems of uneven particle size dispersion and difficulty in obtaining small sizes, and achieve the effects of high penetration contrast, high contrast, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

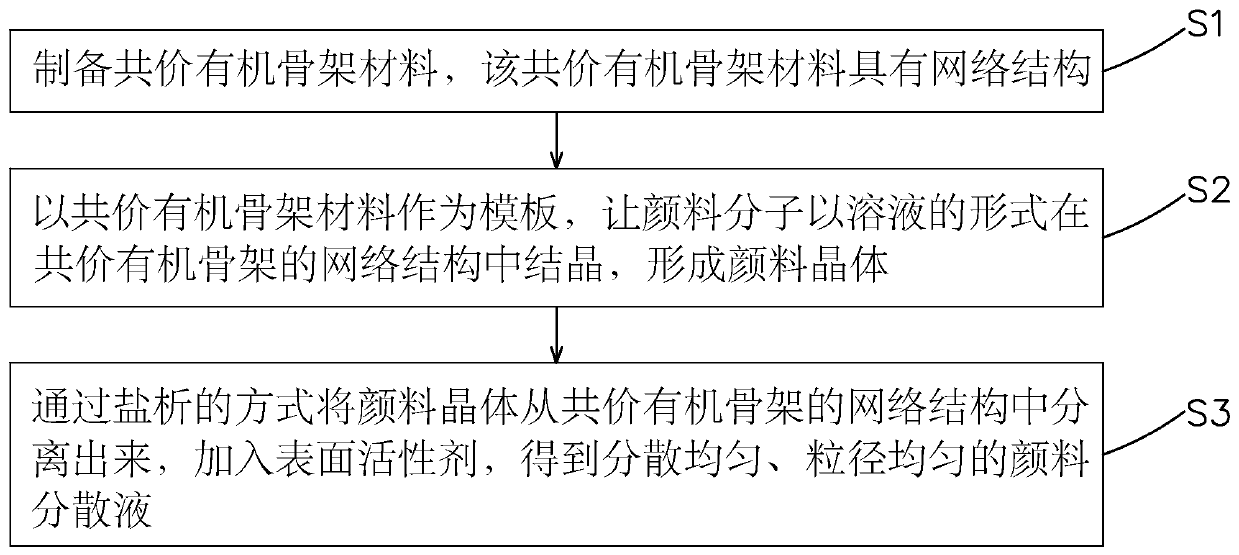

[0032] Example 1. Using the network structure of covalent organic frameworks (Covalent Organic Frameworks, COF) to prepare a pigment dispersion of red pigments

[0033] This embodiment one includes the following steps:

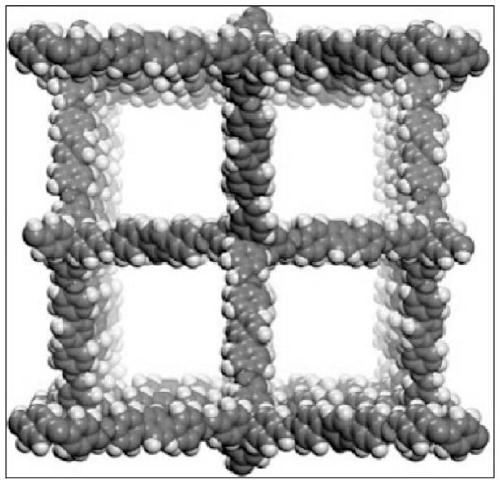

[0034] Step S1, preparing a covalent organic framework material, the covalent organic framework material has a network structure, and during the preparation process, organic building units are connected together through covalent bonds to form a porous framework with a periodic structure.

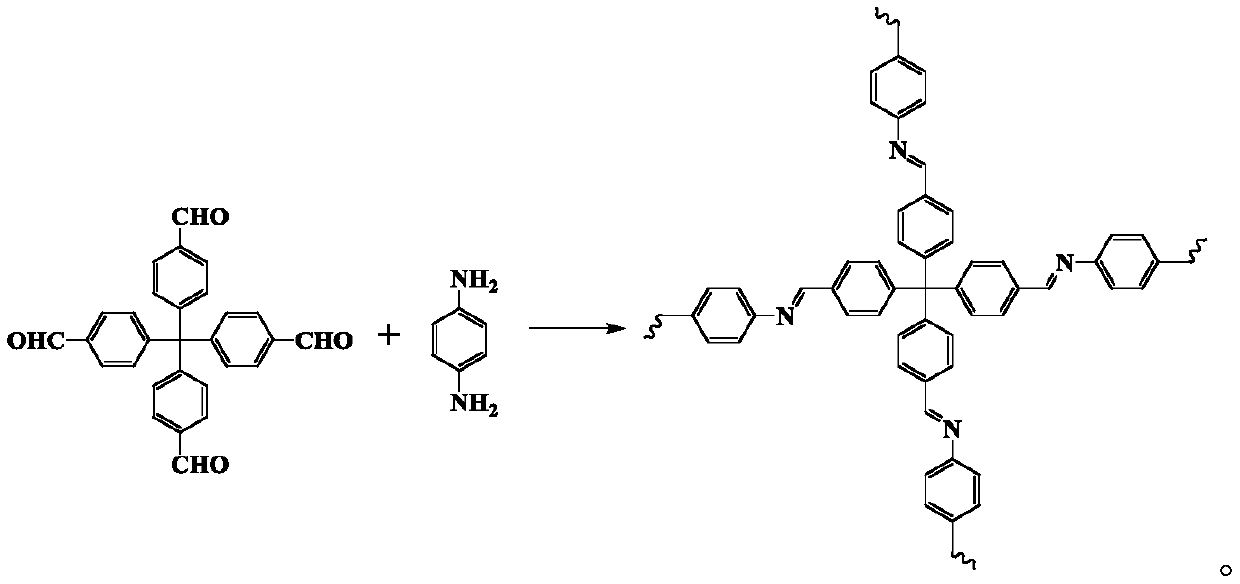

[0035] Specifically, the covalent organic framework material can be produced in the following manner: a Schiff base reaction occurs between a tetrakis(4-formylphenyl)methane compound and a phenylenediamine compound under the action of a catalyst to obtain a covalent organic framework material. Wherein, the tetrakis(4-formylphenyl)methane compound is tetrakis(4-formylphenyl)methane or tetrakis(4-formylphenyl)methane derivative, and the phenylenediamine compound is p- Phenyle...

Embodiment 2

[0048] Embodiment 2, Utilize the network structure of COF to prepare the pigment dispersion liquid of green pigment

[0049] Using the network structure of COF in Example 1 as a template, the green pigment is prepared into a pigment solution. Taking three common green pigments in color photoresists, Pigment Green 7, Pigment Green 36, and Pigment Green 58 as examples, the The covalent organic framework material is placed in the pigment solution, and the nanocrystal structure of the green pigment can be formed after standing still for 120 minutes. The crystals are separated from the network structure of the COF, and then a surfactant is added to obtain a pigment dispersion liquid of green pigments with high dispersion and uniform particle size. Among them, the molecular structural formulas of Pigment Green 7, Pigment Green 36 and Pigment Green 58 are respectively

[0050]

Embodiment 3

[0051] Example 3. Using the network structure of COF to prepare the pigment dispersion of yellow pigment

[0052] Using the network structure of COF in Example 1 as a template, the yellow pigment was prepared into a pigment solution. Taking three common yellow pigments in color photoresist, Pigment Yellow 138, Pigment Yellow 150, and Pigment Yellow 185 as examples, the The covalent organic framework material is placed in the pigment solution, and the nanocrystal structure of the yellow pigment can be formed after standing still for 120 minutes. Crystals are separated from the network structure of COF, and a surfactant is added to obtain a pigment dispersion liquid of yellow pigment with high dispersion and uniform particle size. Among them, the molecular structural formulas of Pigment Yellow 138, Pigment Yellow 150 and Pigment Yellow 185 are respectively

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com