Method for preparing 2-methylfuran through furfural hydrogenation

A technology of methyl furan and furfural, applied in the field of preparation of 2-methyl furan, can solve the problem of low selectivity, achieve good effect, simple preparation process, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

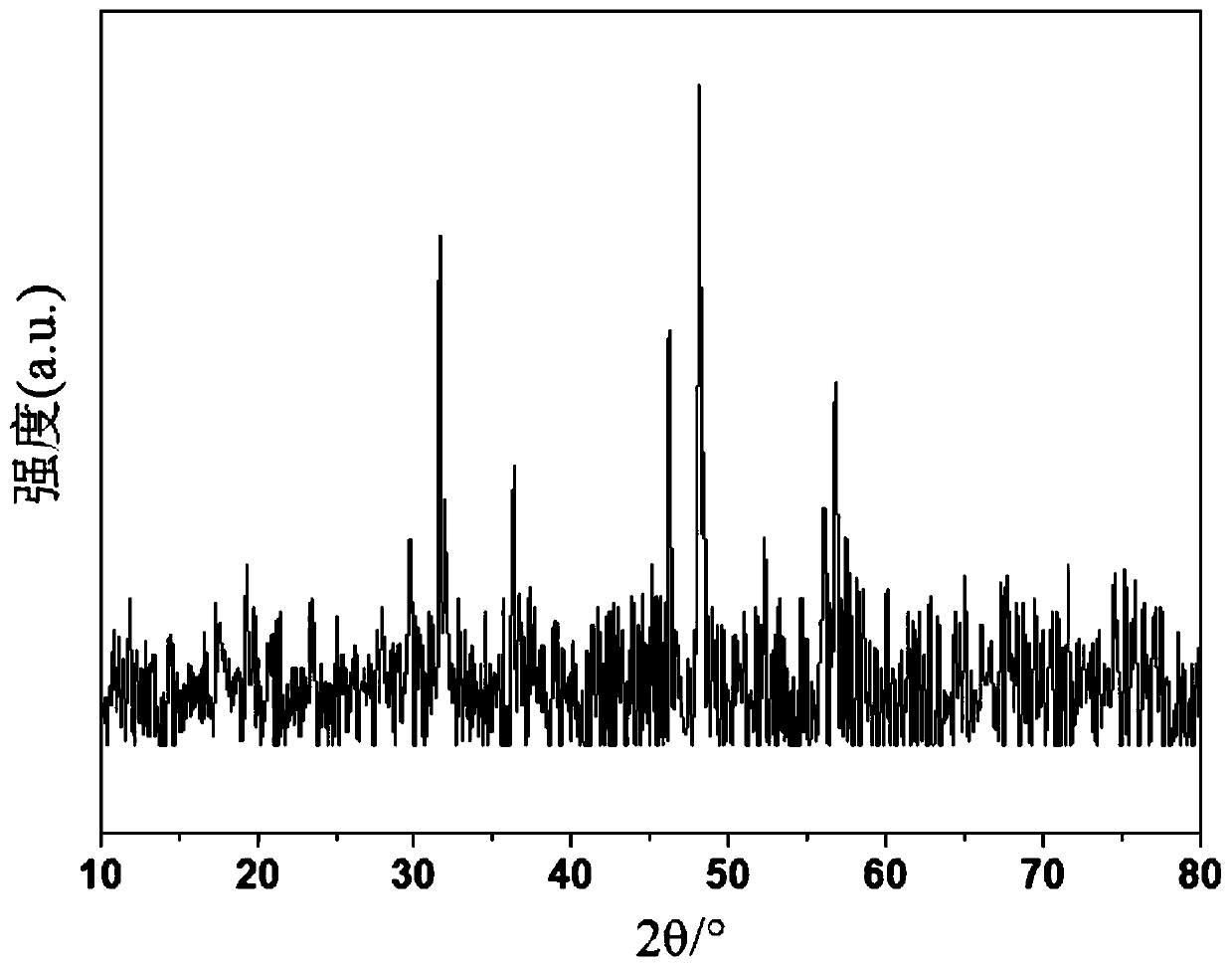

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment 1: This embodiment is a method for hydrogenating furfural to prepare 2-methylfuran, which is specifically completed according to the following steps:

[0015] Put the cobalt phosphide catalyst, furfural and solvent in the autoclave to obtain the mixture, replace the air in the autoclave with hydrogen, and continue to pass in hydrogen until the pressure in the autoclave reaches 0.5MPa~2.5MPa. The temperature is 0.5MPa~2.5MPa, the temperature is 180~230℃, and the reaction is magnetically stirred for 1h~5h under a hydrogen atmosphere, then cooled to room temperature, and the cobalt phosphide catalyst is separated to obtain 2-methylfuran.

[0016] The cobalt phosphide catalyst uses a chromium-free system to avoid environmental pollution and is an environmentally friendly catalyst.

[0017] The cobalt phosphide catalyst has high activity and selectivity, the conversion rate of furfural can reach 100%, and the selectivity of 2-methylfuran can reach over 89%. Com...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the air in the autoclave is replaced with hydrogen for 3 to 4 times. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: this embodiment is different from specific embodiment one or two in that the volume ratio of the furfural to the solvent in the mixture is 1:3-7. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com