High-speed grinding temperature prediction method for particle reinforced titanium-based composite material

A titanium-based composite material and particle-reinforced technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of reduced wear resistance, aggravated grinding wheel wear, shortened service life, etc., to achieve accurate prediction results, Ease of obtaining results and reducing the amount of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

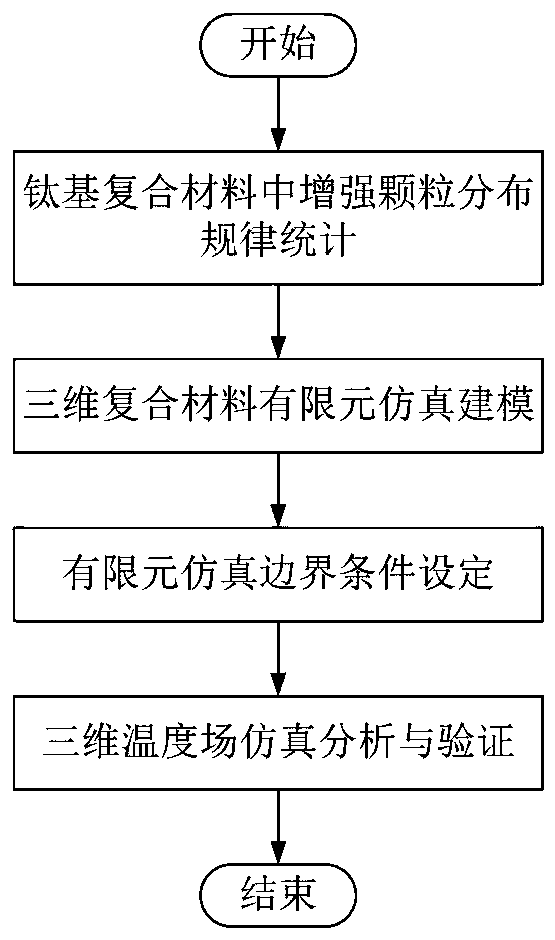

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the specific steps are as follows:

[0046] Step 1: Statistics on the distribution of TiC reinforced particles in titanium matrix composites

[0047] Through the professional image processing software ImageJ, the microstructure of PTMCs captured by the scanning electron microscope was converted into a binary image, such as figure 2 (b), where white represents the Ti-6Al-4V matrix material, and black represents TiC reinforcing particles. Then extract the outer contour curve of TiC particles in the binary image, and solve the centroid map of the reinforced particles, and finally calculate the equimoment equivalent ellipse of the reinforced particle TiC, the result is as follows figure 2 (d) shown. The calculation method is as follows:

[0048] The boundary of TiC particles is expressed as f(x,y) in the rectangular coordinate system xoy, then the geometric moment of the irregular curve can be expressed as formula (1):

[0049]

[0050] The area e...

Embodiment 2

[0077] Embodiment 2 verification test

[0078] In order to further verify the advantages of the three-dimensional composite finite element model in predicting the grinding temperature, the present invention uses a simulation model (three-dimensional homogeneous material simulation model) after the properties of the particle-reinforced titanium-based composite material to be homogenized to simulate the grinding temperature field. Simulation analysis and comparison. Establish a homogeneous model with a length of 6 mm, a height of 1 mm, and a width of 0.1 mm, and assign the following material properties to the workpiece model after dividing the grid. Using the same boundary conditions, the calculated temperature cloud diagram is as follows: Figure 9 Shown, (a) simulation temperature T = 456 ℃ (v w =6m / min, v s =120m / s, a p =20μm); (b) simulation temperature T=730°C (v w =6m / min, v s =120m / s, a p =40μm); (c) simulation temperature T=981°C (v w =6m / min, v s =120m / s, a p =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com