A leaf-shaped nanofe 3 o 4 Preparation method of filled honeycomb sandwich structure wave-absorbing composite material

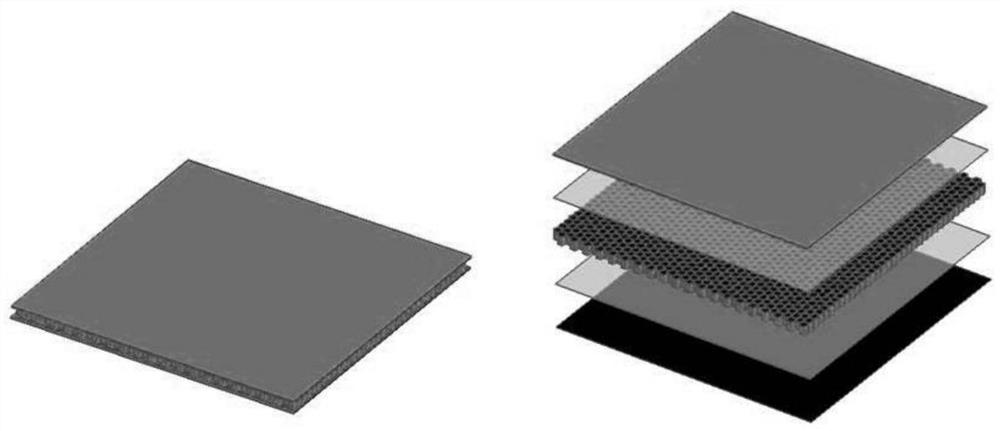

A technology of honeycomb sandwich structure and composite materials, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., which can solve the requirements of easy wear and damage, and the difficulty in realizing the integration of the structure of the absorbing material and the absorbing function of the aircraft To achieve the effect of improving the mechanical strength, improving the structural load-bearing and wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 2.63g of potassium ferricyanide in 80mL of deionized water and stir magnetically for 1 hour; to obtain a potassium ferricyanide solution, pour the obtained red solution into a 100mL polytetrafluoroethylene reactor liner, seal it into a stainless steel In the shell, hydrothermal reaction at 140°C for 48 hours to obtain leaf-shaped nano-α-Fe 2 o 3 , centrifuged at 8000rpm for 10min to collect the precipitate, washed several times with deionized water and alcohol. Dry in a blast oven at 60°C for 24 hours before use.

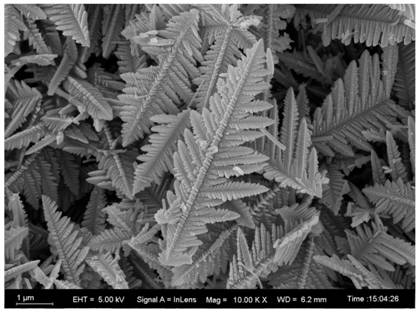

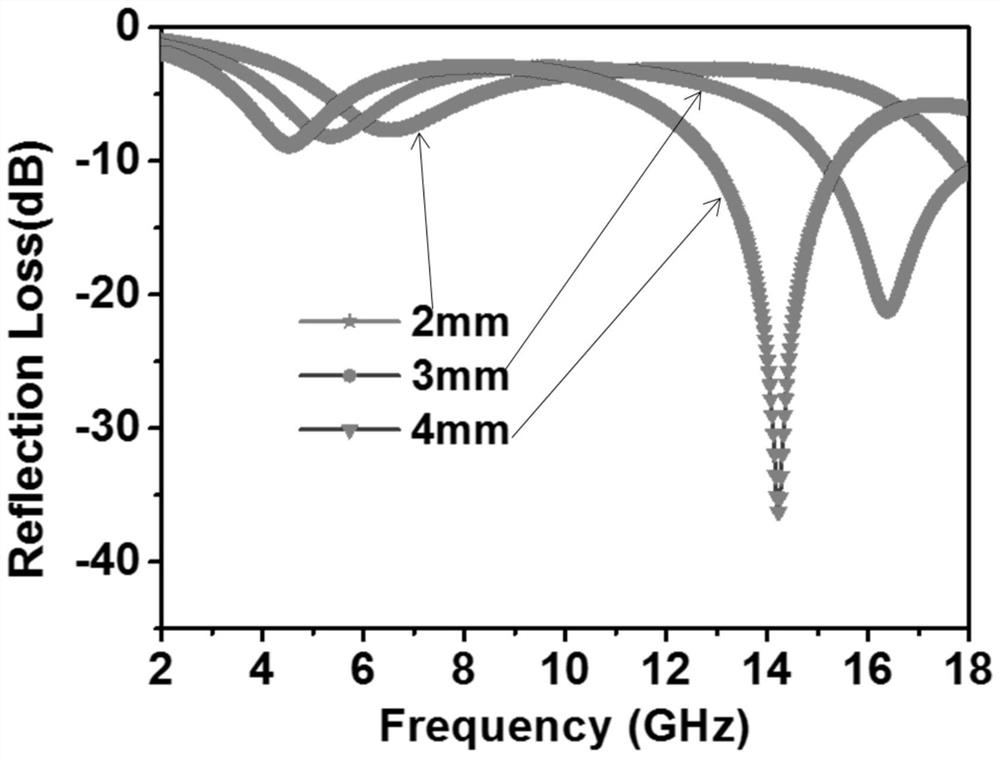

[0024] (2) the leaf-shaped nano-α-Fe obtained in (1) 2 o 3 The sample was placed in a tube furnace and heat-treated at 350°C for 1 hour in a reducing hydrogen and argon mixed gas environment to obtain leaf-like nano-Fe 3 o 4 Absorbing material. Scanning electron microscope photos show that the product is in the shape of a special nano-leaf, as shown in the attached figure 1 shown. Heat treatment process to reduce α-Fe 2 o 3 The flow rat...

Embodiment 2

[0028] (1) Dissolve 2.63g of potassium ferricyanide in 80mL of deionized water and stir magnetically for 1 hour; to obtain a potassium ferricyanide solution, pour the obtained red solution into a 100mL polytetrafluoroethylene reactor liner, seal it into a stainless steel In the shell, hydrothermal reaction at 100°C for 12 hours to obtain leaf-shaped nano-α-Fe 2 o 3 , centrifuged at 7000rpm for 5min to collect the precipitate, washed several times with deionized water and alcohol. Dry in a blast oven at 50°C for 24 hours before use.

[0029](2) the leaf-shaped nano-α-Fe obtained in (1) 2 o 3 The sample was placed in a tube furnace and heat-treated at 300°C for 1 hour in a reducing hydrogen and argon mixed gas environment to obtain leaf-shaped nano-Fe 3 o 4 Absorbing material. Heat treatment process to reduce α-Fe 2 o 3 The flow rates of hydrogen and argon in the mixed gas of hydrogen and argon are 10ml / min and 120ml / min respectively.

[0030] (3) the leaf-shaped nano-F...

Embodiment 3

[0033] (1) Dissolve 2.63g of potassium ferricyanide in 80mL of deionized water and stir magnetically for 1 hour; to obtain a potassium ferricyanide solution, pour the obtained red solution into a 100mL polytetrafluoroethylene reactor liner, seal it into a stainless steel In the shell, hydrothermal reaction at 150°C for 48 hours to obtain leaf-shaped nano-α-Fe 2 o 3 , centrifuged at 9000rpm for 15min to collect the precipitate, washed several times with deionized water and alcohol. Dry in a blast oven at 80°C for 24 hours before use.

[0034] (2) the leaf-shaped nano-α-Fe obtained in (1) 2 o 3 The sample was placed in a tube furnace and heat-treated at 500°C for 2 hours in a reducing hydrogen and argon mixed gas environment to obtain leaf-shaped nano-Fe 3 o 4 Absorbing material. Heat treatment process to reduce α-Fe 2 o 3 The flow rates of hydrogen and argon in the mixed gas of hydrogen and argon are 10ml / min and 120ml / min respectively.

[0035] (3) the leaf-shaped nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com