Chemical mechanical planarization device

A chemical-mechanical and flattening technology, applied in metal processing equipment, grinding machine tools, grinding devices, etc., can solve the problems such as the inability of the wafer to be cleaned in the first time, which is not conducive to industrialized mass production, and increases the waiting time of wafer queuing. , to achieve the effect of mechanization and automation of production, realization of refined production, and elimination of wafer transfer and queuing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

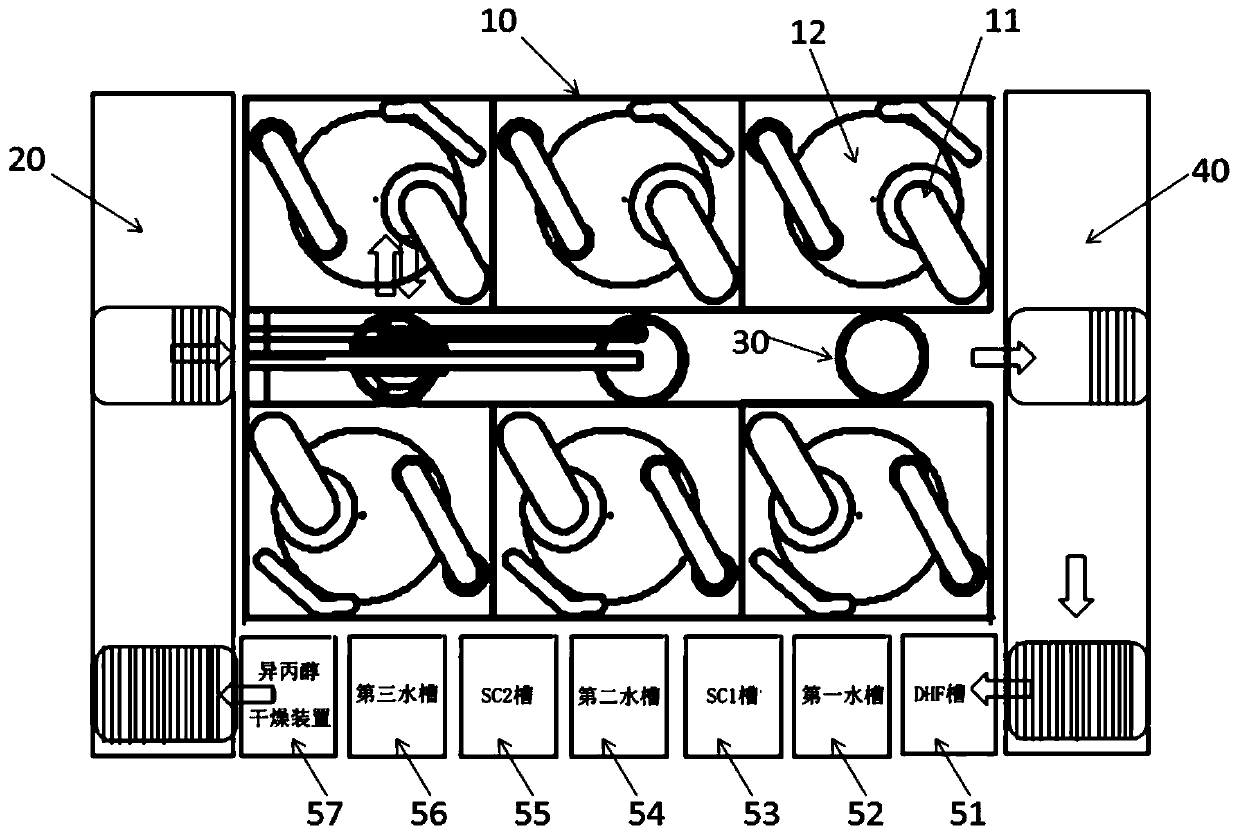

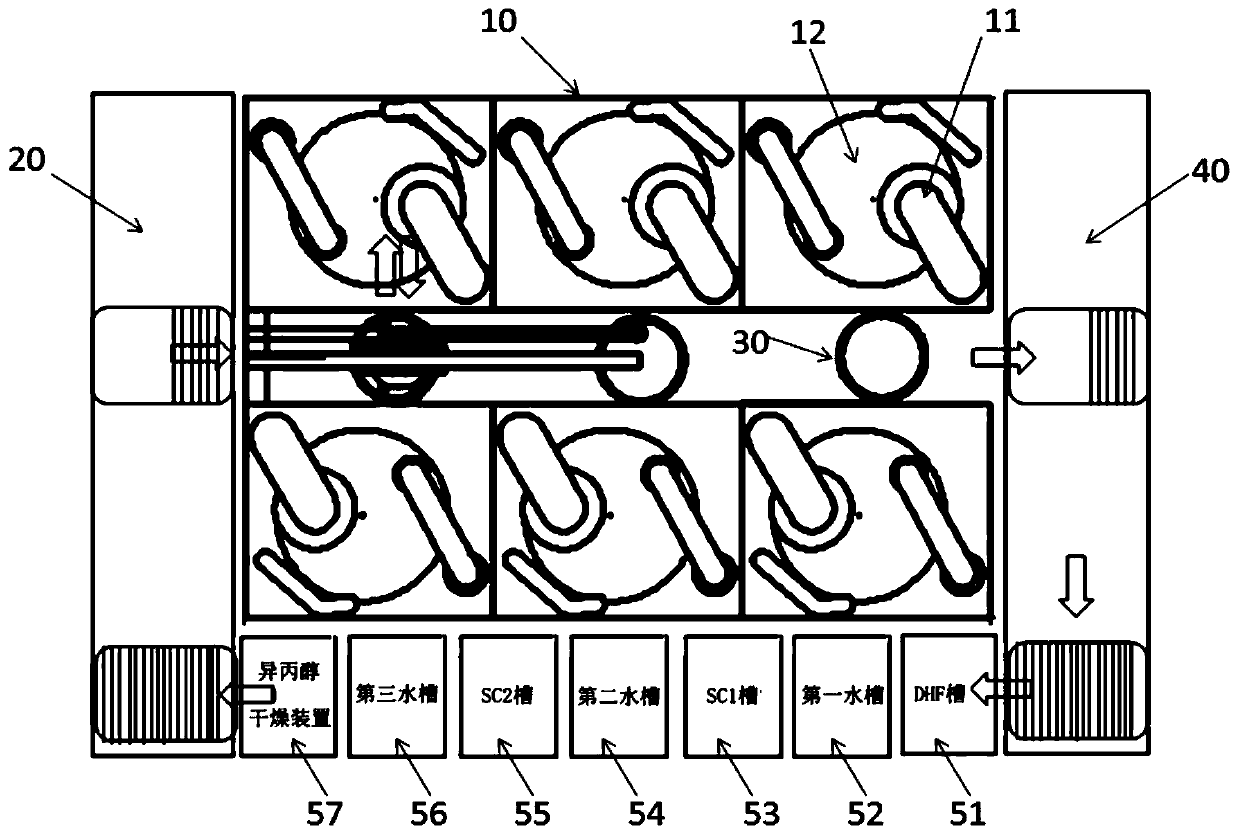

[0023] Such as figure 1 As shown, is a schematic structural diagram of an embodiment of the chemical mechanical planarization equipment of the present invention, and the arrows in the figure indicate the moving direction of the wafer. The chemical mechanical planarization equipment shown in this embodiment comprises: two parallel rows of a total of six polishing units 10, each row is provided with three polishing units 10; For placing wafers to be polished and wafers after cleaning and drying; a row of three loading and unloading tables 30 arranged between two rows of polishing units 10 is used for temporarily placing wafers to be polished and polished wafers, each A loading and unloading platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com