Starting method of supercritical fluid closed cycle engine with mw power level

A supercritical fluid, closed-cycle technology, which is used in machines/engines, mechanical equipment, gas turbines, etc., can solve the problem that the starting methods of ordinary motors and gear drives are complicated in structure and cannot meet the MW power level of closed-cycle engine power and Speed requirements and other issues to achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

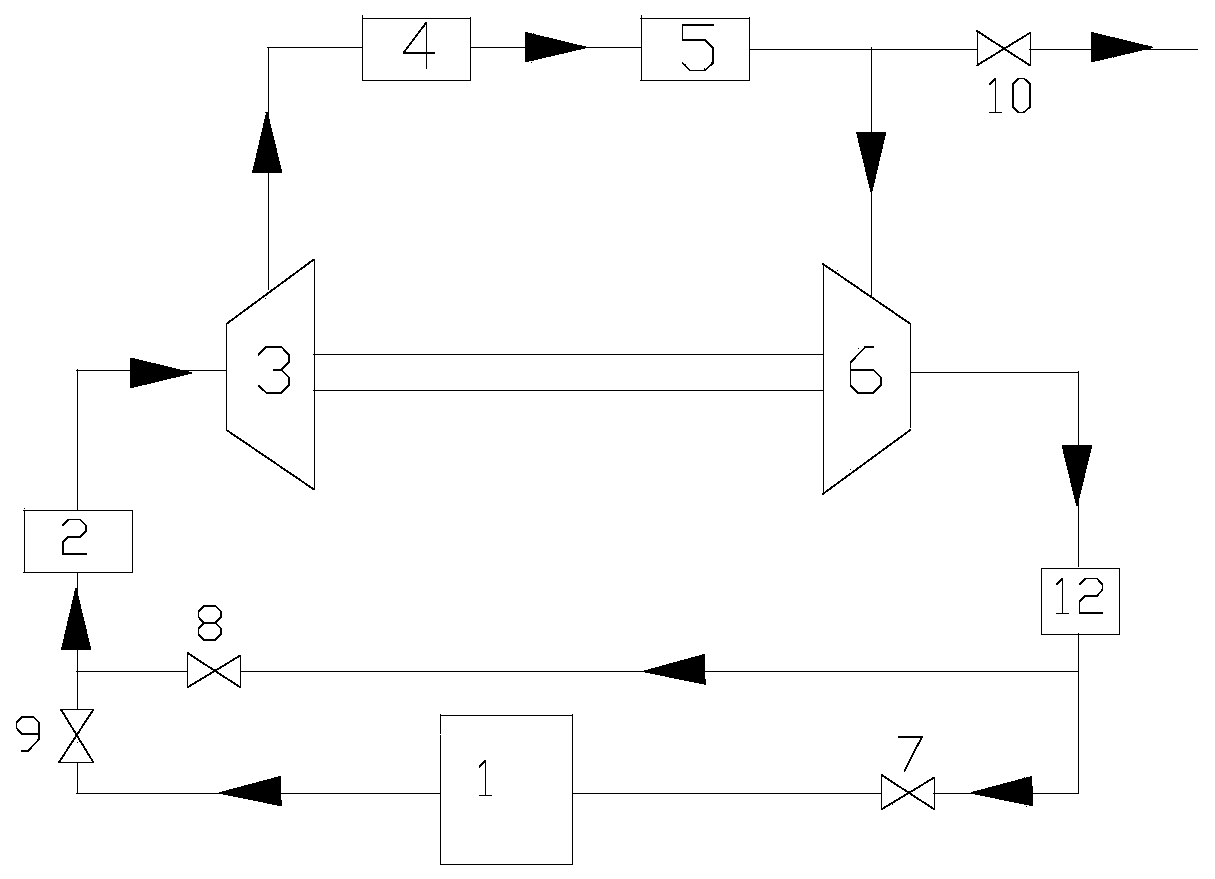

[0033] figure 1 It is a structural schematic diagram of a MW power level supercritical fluid closed cycle engine in a preferred embodiment of the present invention.

[0034] Such as figure 1 As shown, the starting method of the MW power level supercritical fluid closed cycle engine of this embodiment, preferably, the power of the supercritical fluid closed cycle engine is 0.2~5MW, and the MW power level supercritical fluid closed cycle engine includes a storage Gas tank 1, first buffer tank 2, compressor 3, second buffer tank 4, heater 5 and turbine 6, gas storage tank 1, first buffer tank 2, compressor 3, second buffer tank 4, heater 5. The turbine 6 and the gas storage tank 1 are connected in sequence to form a circuit; the compressor 3 and the turbine 6 constitute the core engine of the engine, and the compressor 3 and the turbine 6 are connected to each other through a shaft.

[0035] The starting method of the MW power level supercritical fluid closed cycle engine compr...

Embodiment 2

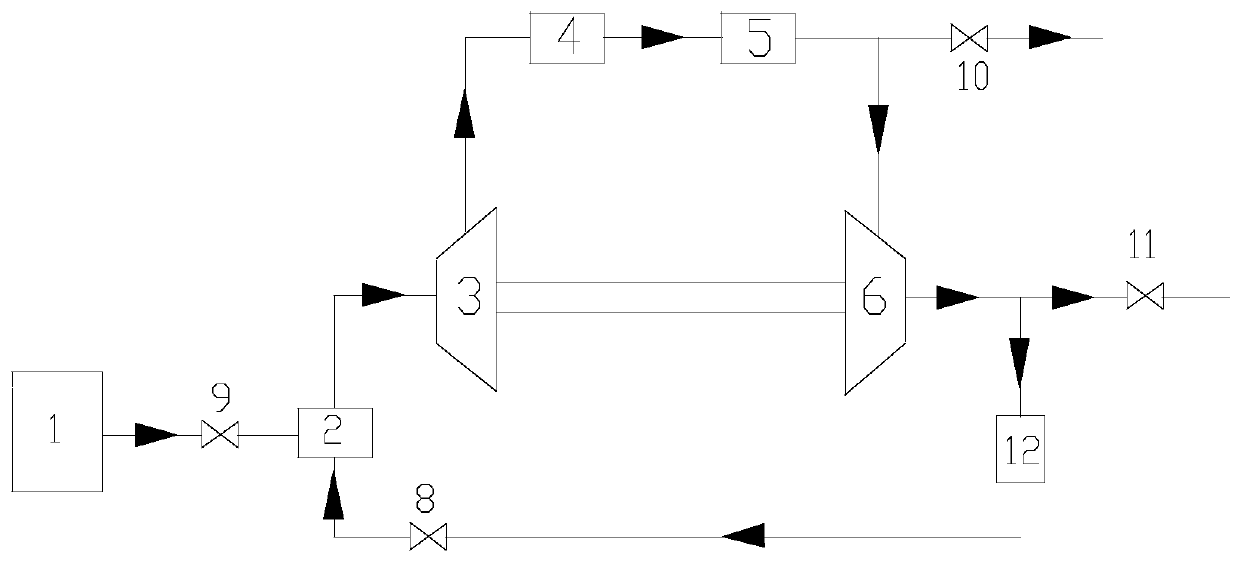

[0051] figure 2 It is another structural schematic diagram of the MW power level supercritical fluid closed cycle engine of the preferred embodiment of the present invention.

[0052] Such as figure 2 As shown, the starting method of the MW power level supercritical fluid closed cycle engine of this embodiment, preferably, the power of the supercritical fluid closed cycle engine is 0.2~5MW, and the MW power level supercritical fluid closed cycle engine includes a storage Gas tank 1, first buffer tank 2, compressor 3, second buffer tank 4, heater 5 and turbine 6, gas storage tank 1 is connected to first buffer tank 2, first buffer tank 2, compressor 3, second The buffer tank 4, the heater 5, the turbine 6, and the first buffer tank 2 are connected in sequence to form a closed circulation loop, and the turbine 6 communicates with the atmospheric environment through the fifth valve 11; the compressor 3 and the turbine 6 constitute the core engine of the engine, and the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com