Multi-layer composite artificial diamond hard alloy wear-resistant part and manufacturing method thereof

A technology of artificial diamond and cemented carbide, which is applied in the direction of earthwork drilling, drilling equipment, drill bits, etc. It can solve the problems of drill bit running vibration, affecting drilling work, and wear of alloy parts, so as to improve the use efficiency and service life, and solve wear and tear Unstable problems, the effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The wear parts of the present invention are mainly used as rolling elements of bearings used in drill bits in oil drilling.

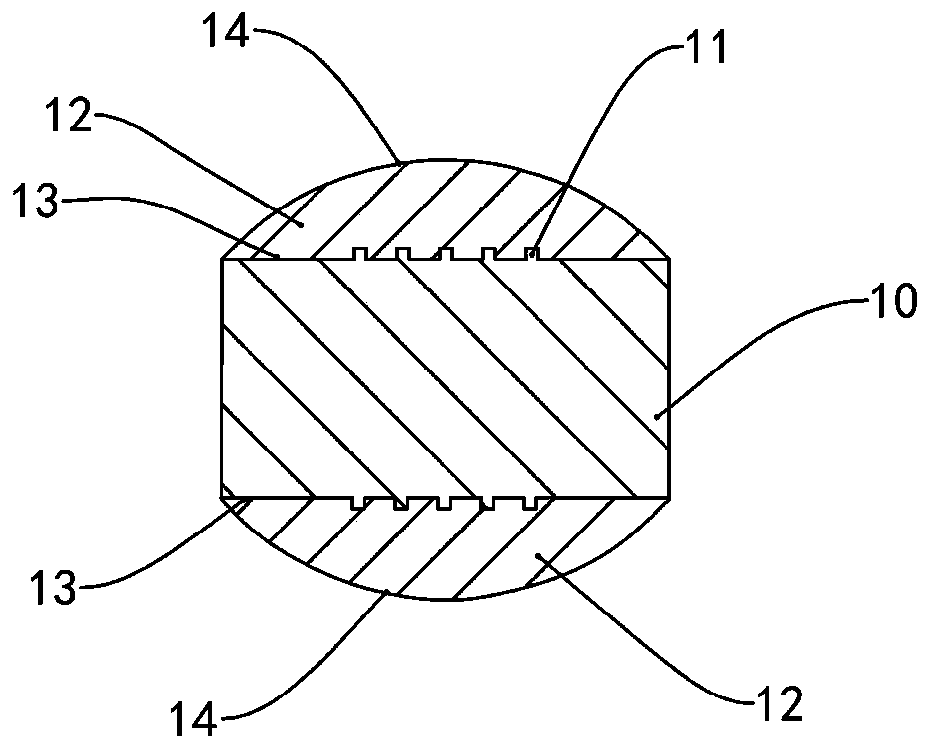

[0026] Such as figure 1 As shown, in the first embodiment of the wear-resistant part, the wear-resistant part includes a cylindrical main body, which is composed of a cemented carbide substrate 10. The cemented carbide substrate 10 has two end faces along its axial direction, and the end faces are provided with There are a plurality of cylindrical teeth 11 protruding from the outside of the cemented carbide base body 10 with respect to the end face. Both ends of the cemented carbide substrate 10 are connected with artificial diamond layers 12 , and the artificial diamond layer 12 and the cemented carbide substrate 10 form an ABA structure. The synthetic diamond layer 12 includes a first face 13 and a second face 14 disposed opposite to each other. The first surface 13 is fixedly connected with the end surface and cooperates with the cylindrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com