Automatic calibrating device of optometry lens box and calibrating method

An automatic calibration and lens technology, which is applied in the direction of determining the position of the lens, determining the optical axis, testing optical performance, etc., can solve problems such as measurement, error, and inability to rotate the lens, so as to achieve accurate and reliable calibration results, facilitate upgrades, and eliminate artificial effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] An automatic calibration device and calibration method for a trial lens case of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

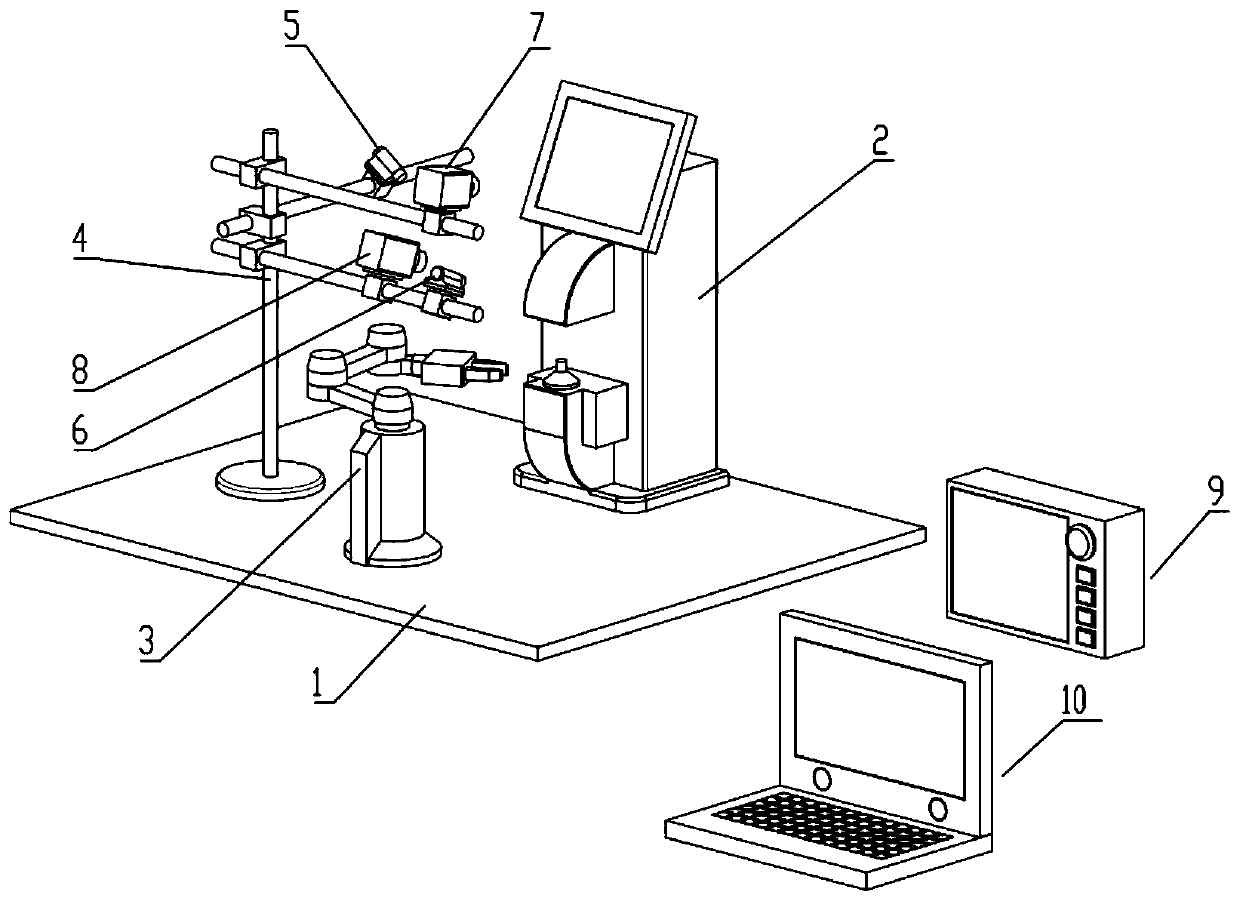

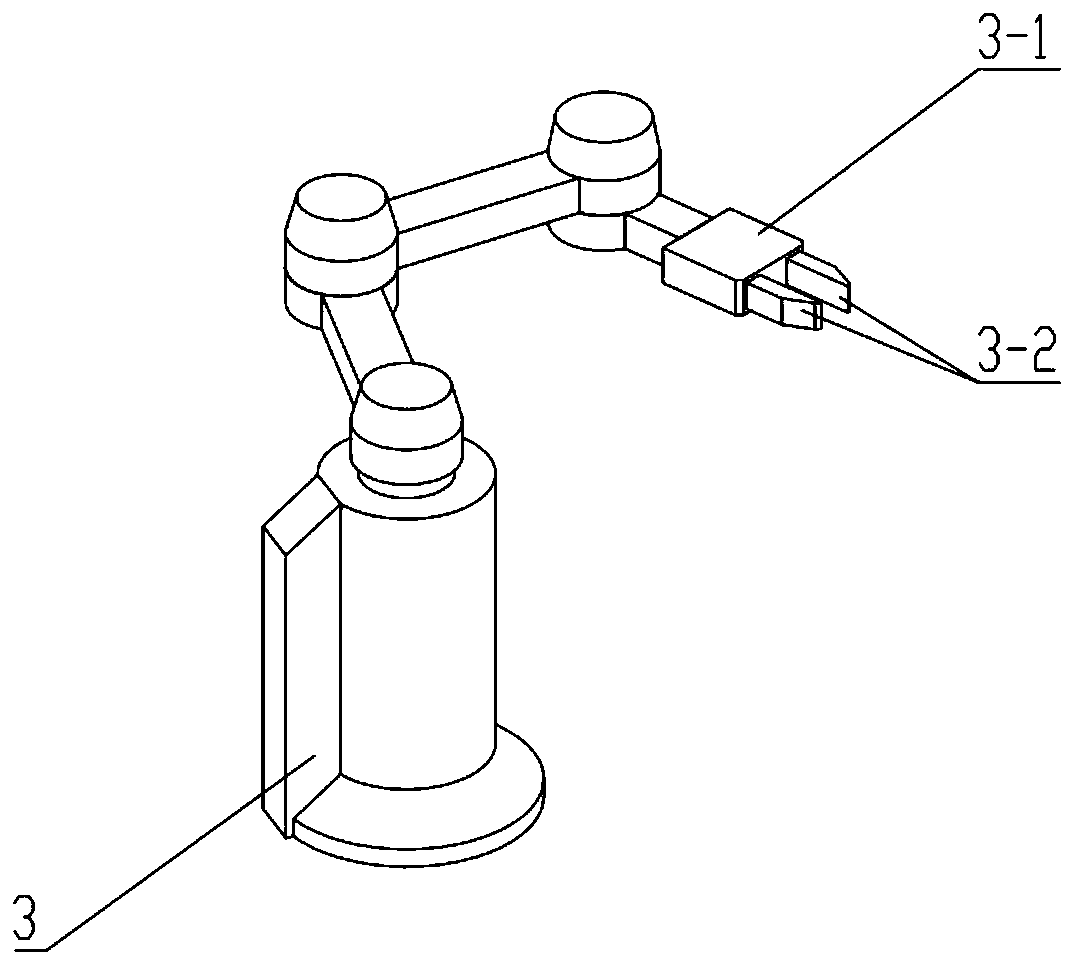

[0064] Such as Figure 1 to Figure 3 As shown, an automatic calibration device for an optometry lens box includes a table top 1, a lens meter 2, a manipulator 3, a bracket 4, a first laser marker 5, a second laser marker 6, a first camera 7, and a second camera 8. Buzzer (not shown in the figure), lower computer 9 and upper computer 10 with automatic calibration software (hereinafter referred to as software);

[0065] The table 1 is used to fix the focal meter 2, the manipulator 3 and the bracket 4;

[0066] The focal meter 2 is a focal meter based on the principle of autofocus, which is the same as the structural principle described in the technical background, except for the printing mechanism, which is used to collect measurement information and displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com