Extruded baked potato chips and preparation method thereof

A production method and technology of potato chips, which are applied in the field of baked snack food and its production, can solve the problems of high blood pressure, easy destruction of nutritional elements, low nutritional value, etc., achieve balanced nutrition, simple and controllable production process, and improve the effect of taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

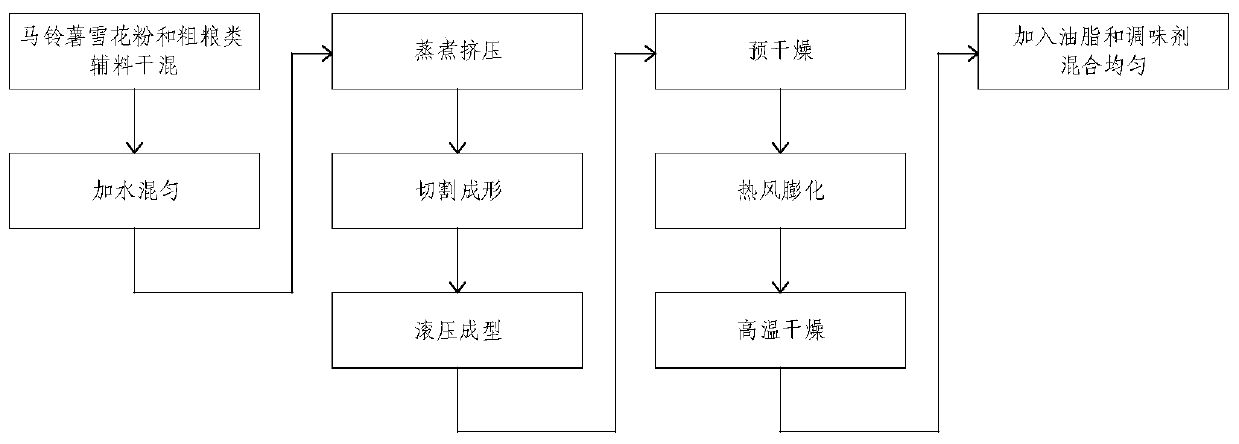

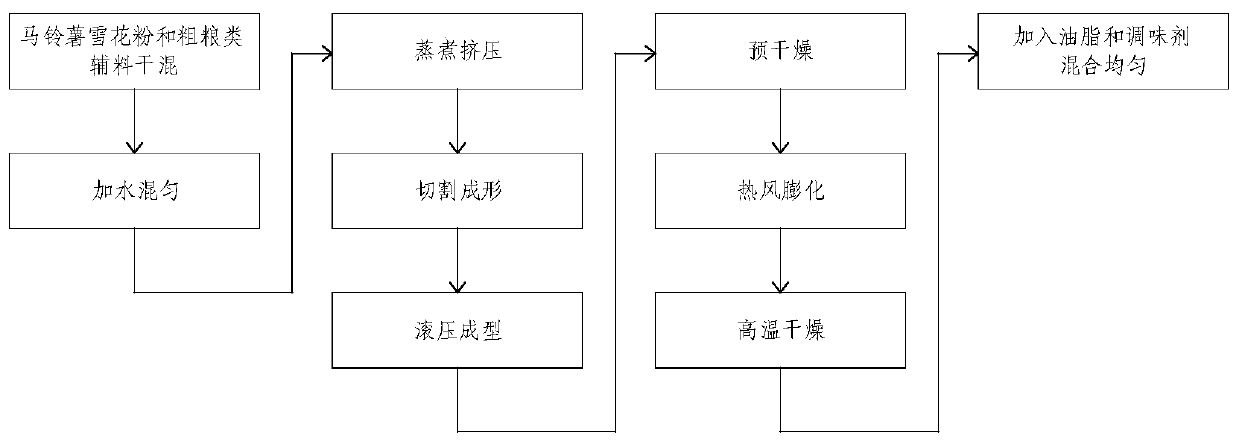

[0041] The embodiment of the present invention provides a kind of preparation method of extruding baked potato chips with spicy taste, such as figure 1 As shown, the specific process is as follows:

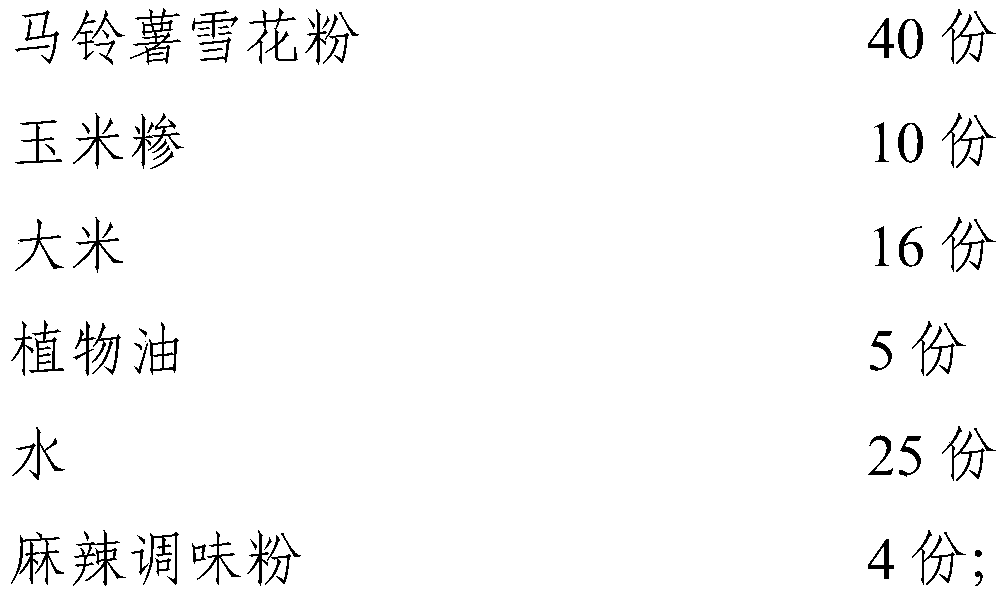

[0042] S1. Weigh each component according to the following formula:

[0043]

[0044] Mix all raw materials except vegetable oil and spicy seasoning powder evenly, cook and mature the raw materials in four stages at 50-120°C, then extrude them through a die to form swollen strips, and then cut them into short strips and press them by calendering Machine pressed into potato chip dough;

[0045] S2. Pre-drying the potato chip dough in step S1 at 80° C. for 4 minutes;

[0046] S3. Hot air puffing the baked and pre-dried potato chip dough at 140-200° C. for 2-20 minutes to obtain puffed potato chips;

[0047] The hot-air puffing adopts a high-temperature short-time instant puffing process, specifically, firstly, it is puffed at a high temperature at 185°C for 3.5 minutes, and th...

Embodiment 2

[0051] The embodiment of the present invention provides a method for making sea salt-flavored squeezed baked potato chips, the specific process is as follows:

[0052] S1. Weigh each component according to the following formula:

[0053]

[0054]Mix all raw materials except vegetable oil and sea salt seasoning powder evenly, cook and mature the raw materials in four stages at 50-120°C, then extrude them through a die to form swollen strips, and then cut them into short strips and then calender them Machine pressed into potato chip dough;

[0055] S2. Pre-drying the potato chip dough in step S1 at 100° C. for 5 minutes;

[0056] S3, hot-air puffing the baked and pre-dried potato chip dough at 175° C. for 7.5 minutes to obtain puffed potato chips;

[0057] S4, drying the puffed potato chips cooled in step S3 at a high temperature of 105° C. for 5 minutes, and cooling;

[0058] S5. Add vegetable oil and sea salt seasoning powder to the puffed potato chips cooled in step S4 ...

Embodiment 3

[0060] The embodiment of the present invention provides a method for making yogurt-flavored squeezed baked potato chips, the specific process is as follows:

[0061] S1. Weigh each component according to the following formula:

[0062]

[0063] Mix all the raw materials except vegetable oil and yogurt seasoning powder evenly, cook and mature the raw materials in four stages at 50-120°C, and then extrude them through a die to form swollen strips, then cut them into short strips and press them by calendering Machine pressed into potato chip dough;

[0064] S2. Pre-drying the potato chip dough in step S1 at 70° C. for 8 minutes;

[0065] S3, hot-air puffing the baked and pre-dried potato chip dough at 165° C. for 10 minutes to obtain puffed potato chips;

[0066] S4. Dry the puffed potato chips cooled in step S3 at 85° C. for 10 minutes at high temperature, and cool down;

[0067] S5. Add vegetable oil and yogurt seasoning powder to the puffed potato chips cooled in step S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com