Fracture toughness testing device under low temperature high pressure hydrogen charged environment and method thereof

A fracture toughness, low temperature and high pressure technology, applied in the field of fracture toughness testing devices, can solve the problems of not involving low temperature and high pressure test environment, low thermal efficiency, and inability to keep warm, so as to increase authenticity and reliability, reduce refrigeration links, and improve refrigeration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

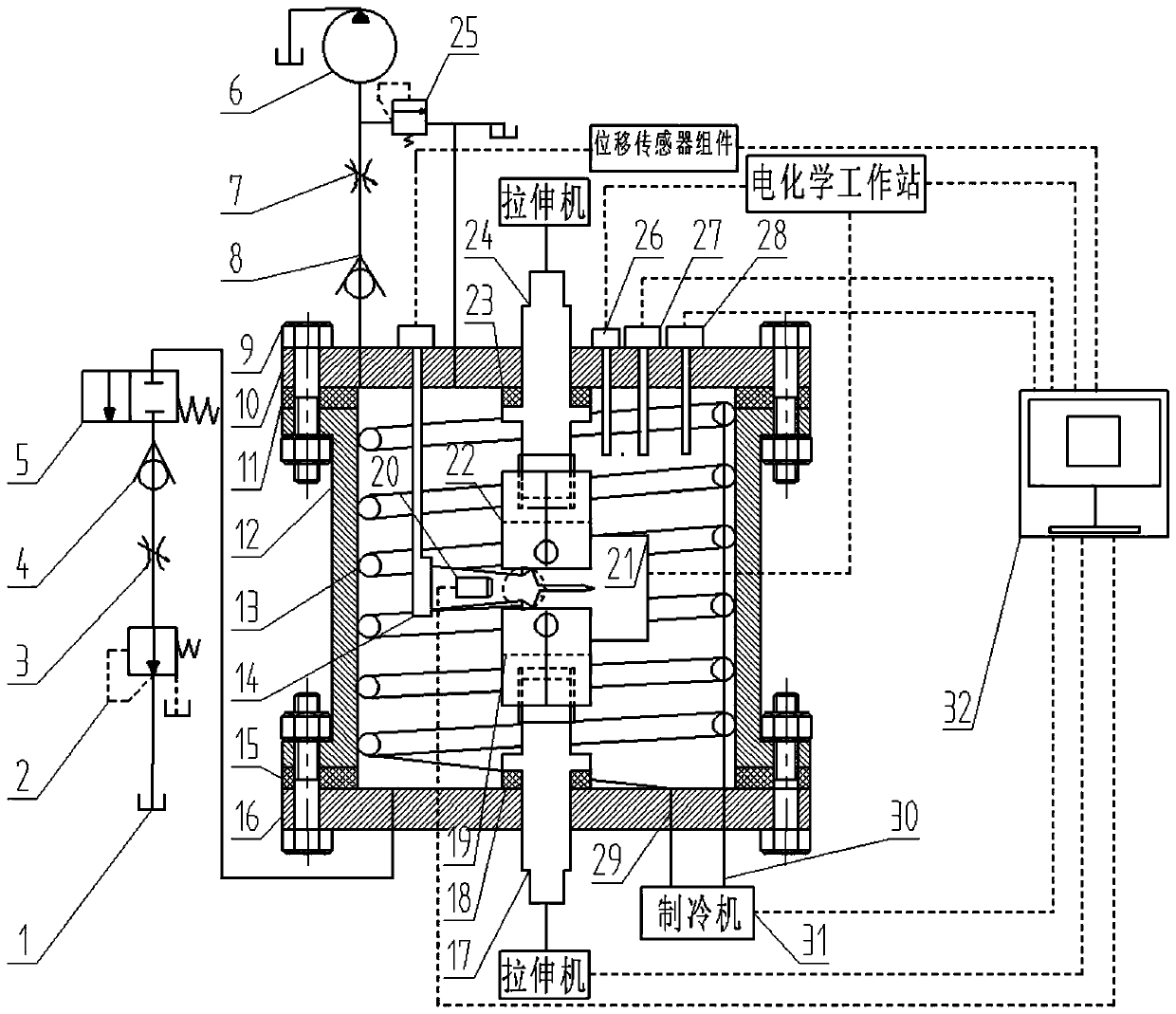

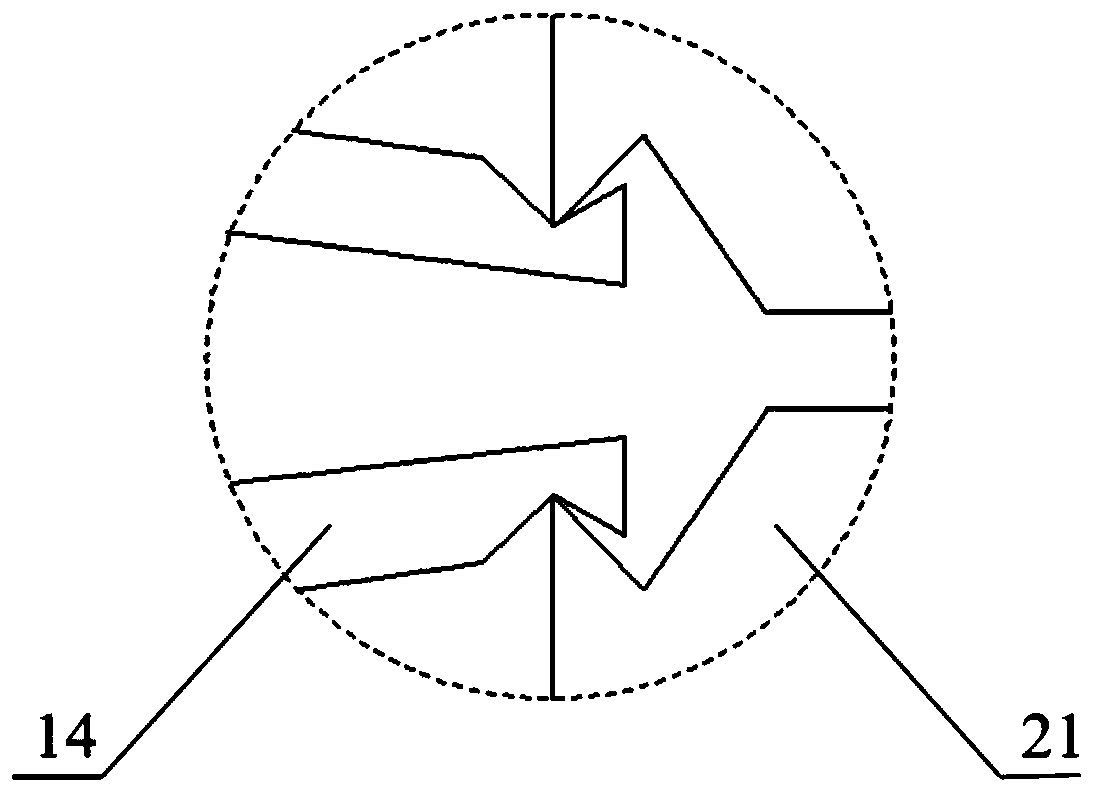

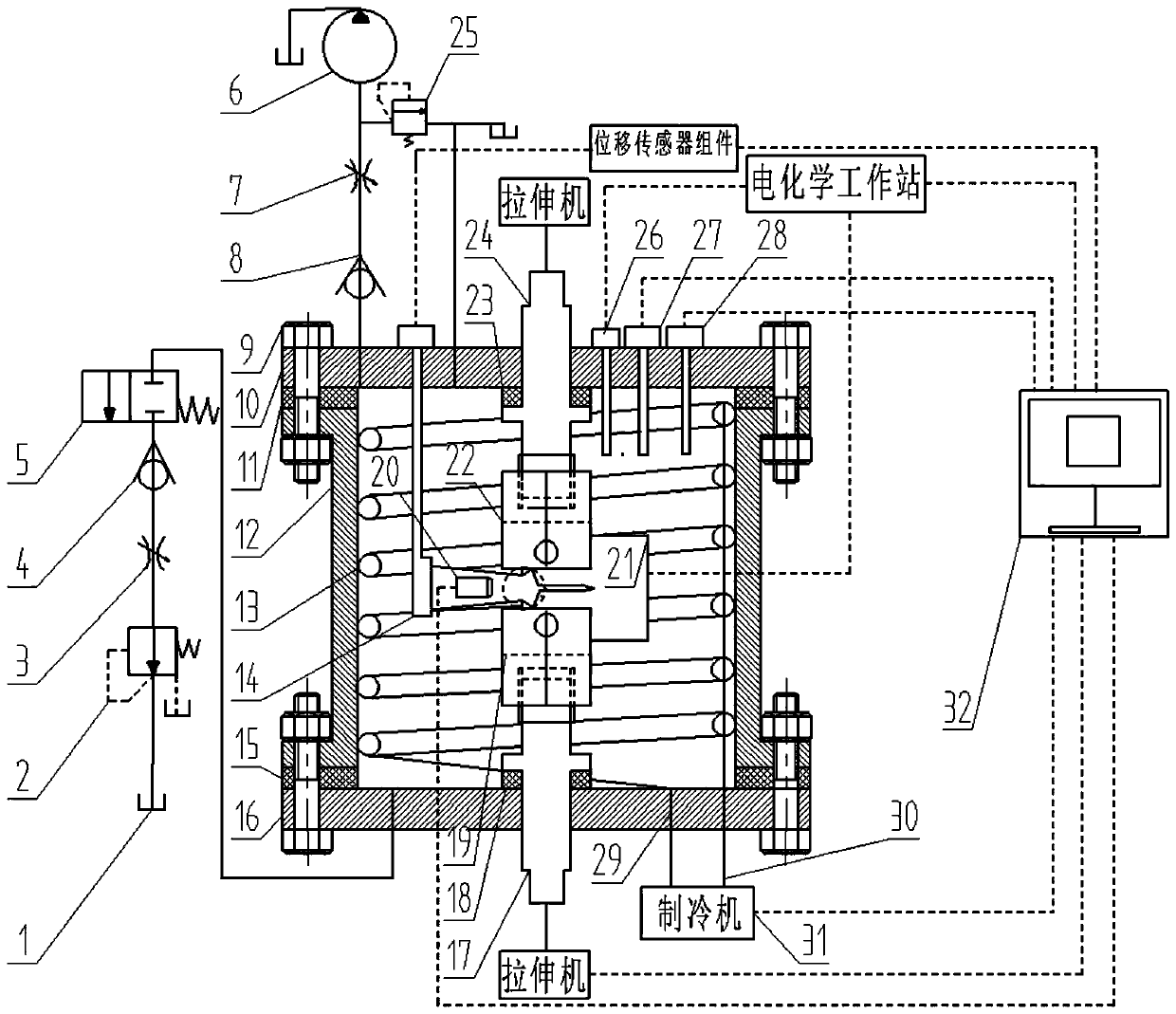

[0031] Such as figure 1 and figure 2 As shown, the fracture toughness test device under the low temperature and high pressure hydrogen charging environment of the present invention includes a closed box, a stretching device, a refrigeration component, a liquid pressurization component, an electrochemical component, a detection component and an industrial computer 32; A stretching device is provided on the closed box, and the liquid pressurization component is used to provide a high-pressure electrolyte solution inside the closed box; the refrigeration component is used to cool down the electrolyte solution; the electrochemical component is used to Hydrogen gas is generated on the surface of the tensile sample 21; the detection component is used to detect the pressure an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com