Lithium slag treatment method

A treatment method, lithium slag technology, applied in sustainable waste treatment, solid waste management, lithium carbonate; Pollution hazards of land and environment, simple treatment method, and high comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

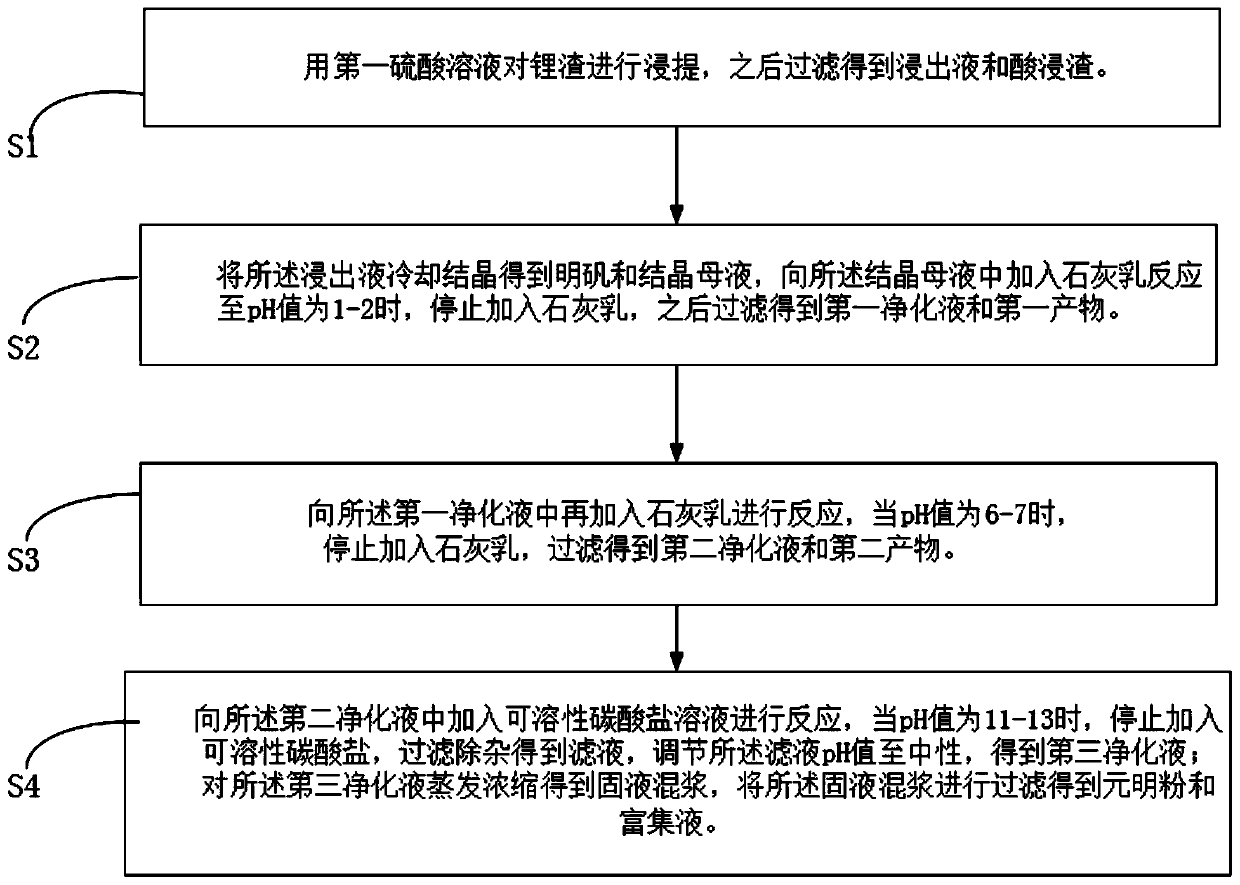

Method used

Image

Examples

Embodiment 1

[0053] A kind of processing method of lithium slag:

[0054] 1. Use a sulfuric acid solution with a mass concentration of 30% to carry out acid leaching on the lithium slag at a temperature of 90°C. The liquid-solid mass ratio of the sulfuric acid solution to the lithium slag is 4:1. After 1 hour of acid leaching, filter to obtain the leaching solution. In the lithium slag, 88 Lithium, Rubidium, Cesium, Potassium, Aluminum and Sodium above % are dissolved into the leach solution, and the filter cake is washed to be acid leaching residue, which is mainly quartz and gypsum, which can be used as concrete admixtures.

[0055] 2. The leaching liquid is cooled and crystallized at -10°C to obtain alum and crystallization mother liquor. Add lime milk to the crystallization mother liquor to react until the pH value is 1, stop adding lime milk, and filter to obtain the first purified liquid and the first product. The first The product is gypsum.

[0056] 3. Add milk of lime to the firs...

Embodiment 2

[0061] A kind of processing method of lithium slag:

[0062] 1. Use a sulfuric acid solution with a mass concentration of 50% to carry out acid leaching on the lithium slag at a temperature of 70°C. The liquid-solid mass ratio of the sulfuric acid solution to the lithium slag is 3:1. After 2 hours of acid leaching, filter to obtain the leaching solution. In the lithium slag, 88 Lithium, Rubidium, Cesium, Potassium, Aluminum and Sodium above % are dissolved into the leach solution, and the filter cake is washed to be acid leaching residue, which is mainly quartz and gypsum, which can be used as concrete admixtures.

[0063] 2. The leaching liquid is cooled and crystallized at a temperature of 0°C to obtain alum and crystallization mother liquor. Add lime milk to the crystallization mother liquor to react until the pH value is 2, stop adding lime milk, and filter to obtain the first purified liquid and the first product, the first product For plaster.

[0064] 3. Add milk of li...

Embodiment 3

[0069] A kind of processing method of lithium slag:

[0070] 1. Use a sulfuric acid solution with a mass concentration of 70% to carry out acid leaching of the lithium slag at a temperature of 50°C. The liquid-solid mass ratio of the sulfuric acid solution to the lithium slag is 2:1. After 3 hours of acid leaching, filter to obtain the leaching solution. In the lithium slag, 88 Lithium, Rubidium, Cesium, Potassium, Aluminum and Sodium above % are dissolved into the leach solution, and the filter cake is washed to be acid leaching residue, which is mainly quartz and gypsum, which can be used as concrete admixtures.

[0071] 2. Cool and crystallize the leaching solution at -5°C to obtain alum and crystallization mother liquor. Add lime milk to the crystallization mother liquor to react until the pH value is 1.5, stop adding lime milk, filter to obtain the first purified liquid and the first product, the first The product is gypsum.

[0072] 3. Add milk of lime to the first puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com