PPS tube and production method thereof andmachine used in cooperation withproduction method

A processing method and technology of mixture, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of inability to extrude, weak fluidity, etc., and achieve the effects of weak fluidity, reducing flange connections and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

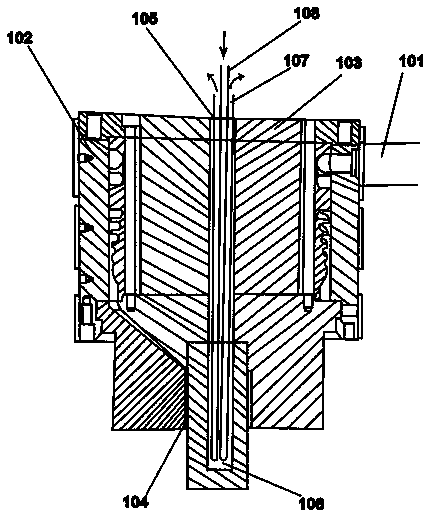

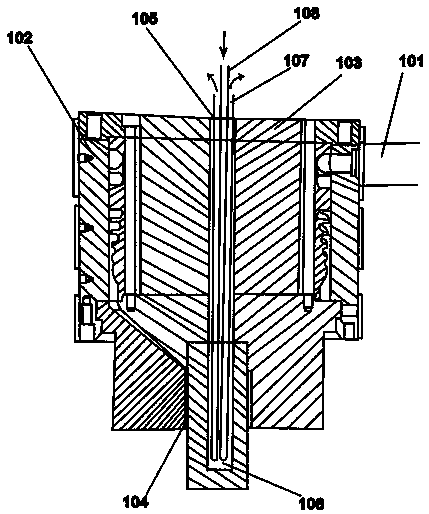

Image

Examples

Embodiment 1

[0022] Because there is a funnel on the top of the existing twin-screw extruder, when processing the pellets, you only need to take the mixed mixture and put it upside down in the funnel, so the overall weight of the mixture is not limited when mixing, just according to the weight The percentage is calculated as 100%. In a mixture of high-purity flake graphite and silane coupling agent, high-purity flake graphite accounts for 99% and silane coupling agent accounts for 1%. Stirring treatment, since most high-speed mixers have temperature control devices, when the early temperature is lower than 80°C, it can not be counted in the stirring time. When the high-purity mixer only needs to stir for three to five minutes, the high-purity flake graphite and silane coupling agent can be evenly stirred. After the mixture of high-purity flake graphite and silane coupling agent is evenly stirred, we are mixing Pour the sulfide into the high mixer for secondary mixing. At the same time, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com