Casting method of a hundred-ton integrated metal container for storage and transportation of spent fuel

A metal container and spent fuel technology, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of difficult elimination of slag inclusions on the surface and difficulty in meeting flaw detection standards, so as to improve self-feeding capacity and reduce shrinkage porosity , Reduce the effect of shrinkage cavity shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 A molding process method of a metal container for integrated spent fuel storage and transportation of 100 tons. The material of the metal container for integrated spent fuel storage and transportation is EN-GJS-400-18-LT.

[0033] It is casted with ductile iron. The outer mold is composed of multiple parts and a cover mold. The large core is a sand skeleton with chilled iron embedded in the molding sand. The bottom molding sand is made of furan resin sand. After the molding is completed, it is compacted by micro-shock.

[0034] The pouring method adopts ladle pouring, and two ladles are used in total to pour the cast iron liquid into the sprue cup, and then enter the mold through the sprue, runner, and inner sprue.

[0035]Specifically, according to the requirements of the smelting process, the smelting ingredients are carried out, and the method of adding nodulizers, inoculants and inoculating with the flow is adopted; after the obtained molten cast iron is sp...

Embodiment 2

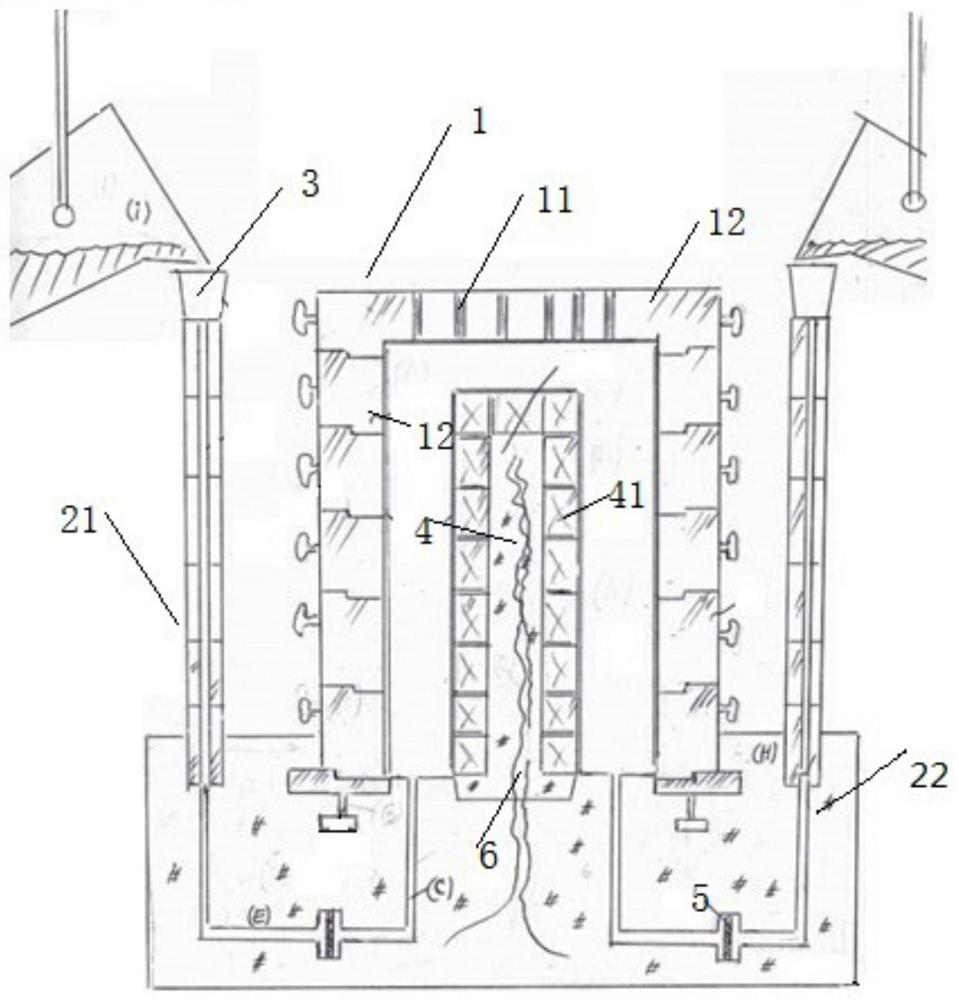

[0037] Example 2 A combined iron-sand mold for making a hundred-ton integrated metal container for storage and transportation of spent fuel

[0038] It consists of a metal mold 1, a large core 4 and a sand box 2. The metal mold includes an outer mold 12 and a cover mold. The metal mold is supported and fixed by the bottom box. The outer mold 12 adopts an iron mold, and the outer mold The material is cast iron, and the outer mold is divided into 6 sections to facilitate processing and save time. From bottom to top, they are 1#-6# modules, and white glue is applied to the joints of the iron molds to ensure its tightness.

[0039] The big ni core 4 adopts a sand structure, and the outer surface of the big ni core is a cold iron 41, and the cold iron 41 is embedded in the sand. The sand box 2 includes a bottom box and a sprue sand box 21. The gating system is formed by the bottom box and the sprue sand box 21. Both of them adopt a sand structure. The sprue sand box 21 is a sprue,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com