Sound insulation performance test window and test method for variable-size vehicle sound package

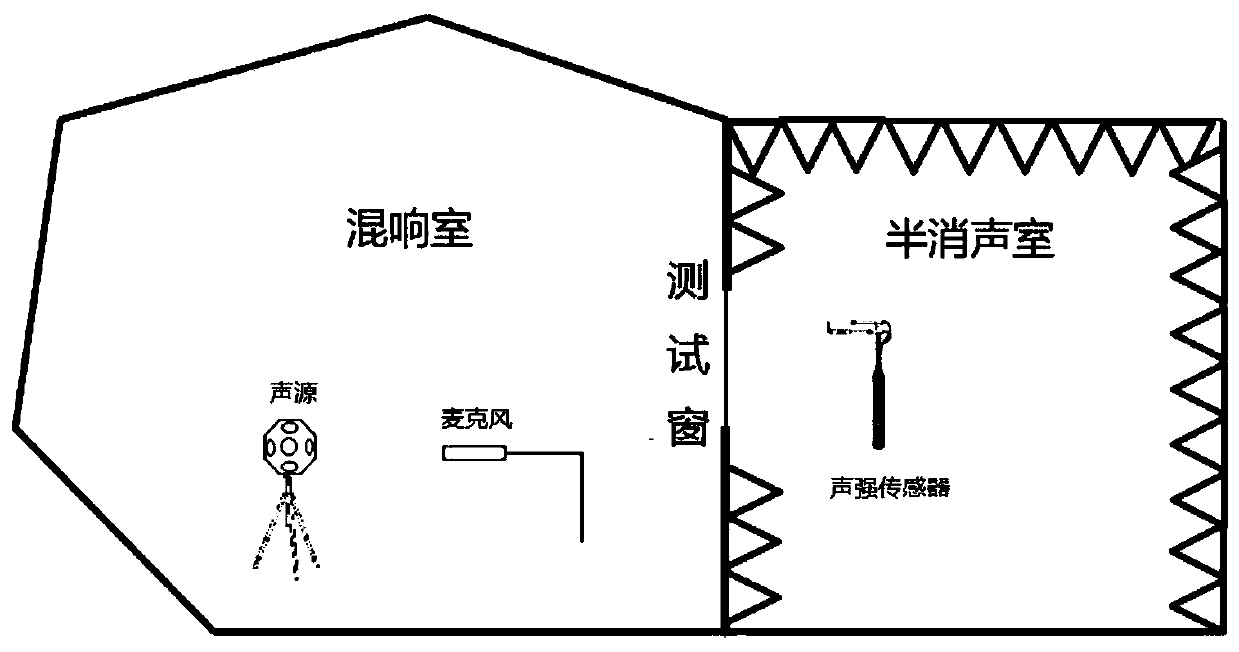

A technology of acoustic bag and test window, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, instruments, and analysis materials, etc. It can solve the problem of inability to complete the sound insulation test of the vehicle sound bag, the difficulty of ensuring the sealing and sound insulation, and the time-consuming and other problems, to achieve the effect of simple structure, ensuring sound insulation performance, and reducing the weight of the window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

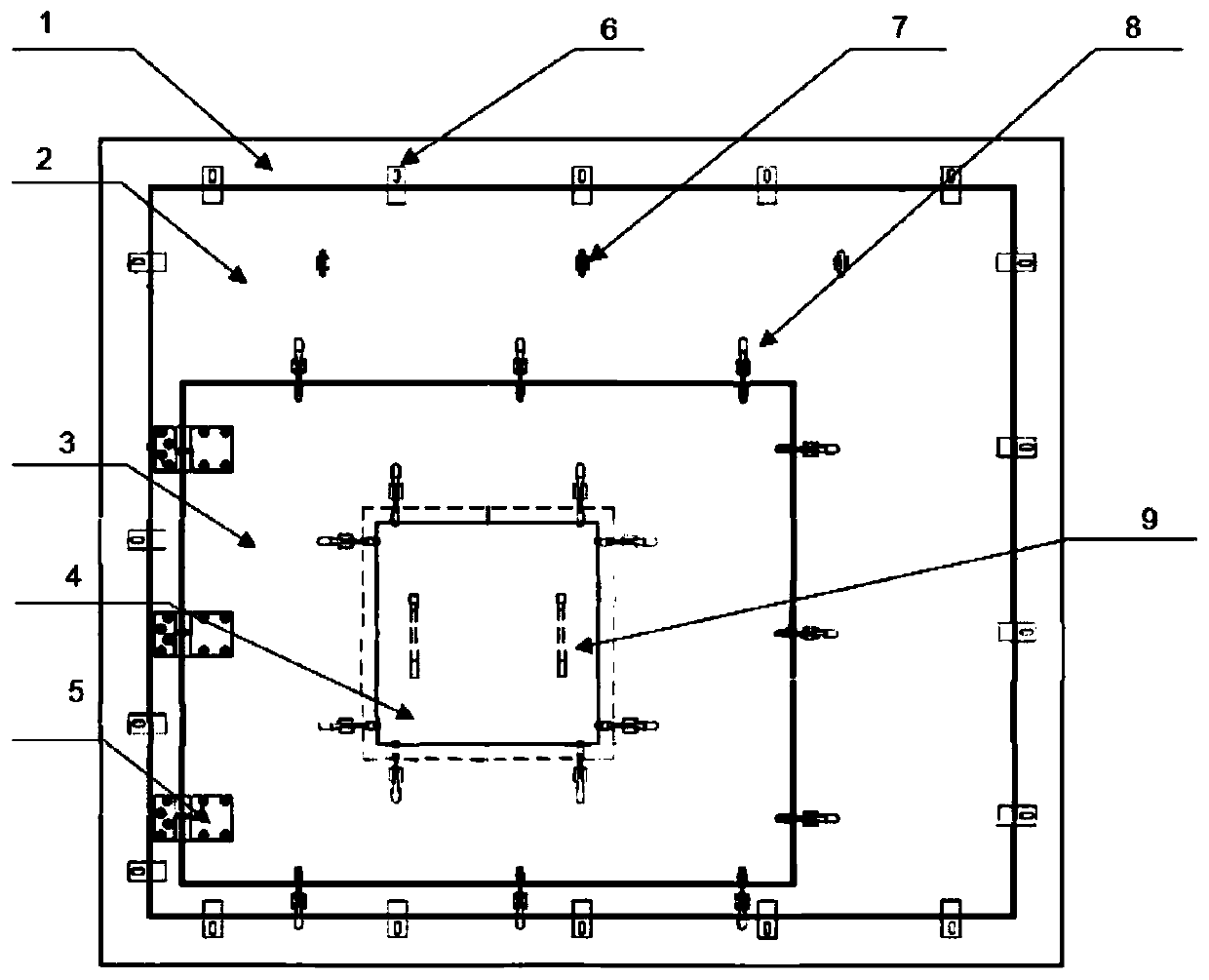

[0069] This test window and test method embodiment 1 are as follows:

[0070] Sound insulation performance test of a car carpet raw material:

[0071] 1. The raw material size of the test carpet is 650mmX650mm;

[0072] The size of the sample is smaller than the size of the small window 670mmX670mm, and the small window is used for testing;

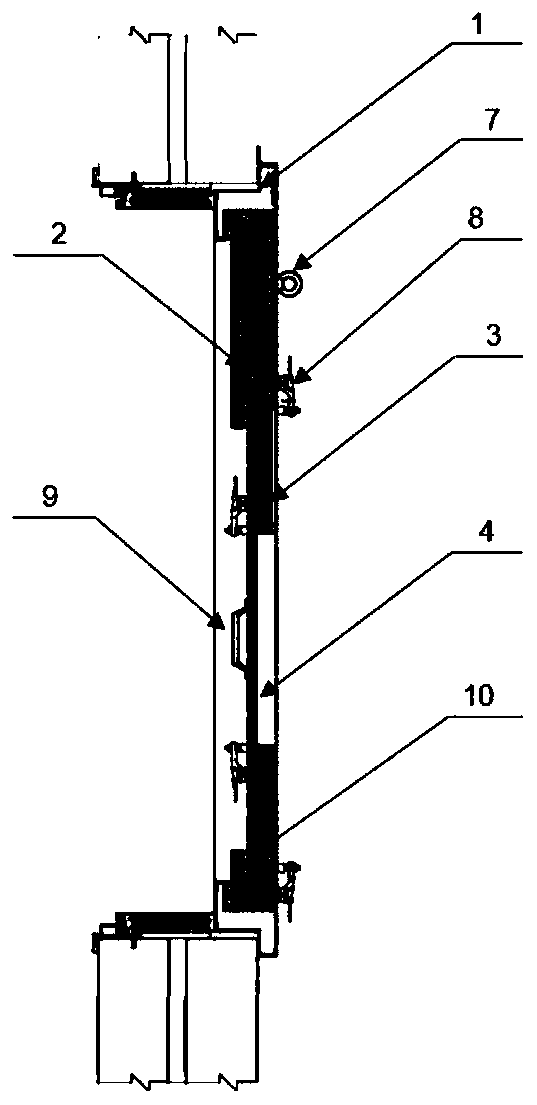

[0073] 2. Open the quick clamp 8 between the middle window panel 3 and the small window panel 4;

[0074] Take off the small window plate 4 through the stainless steel handle 9 on the side of the semi-anechoic chamber;

[0075] Install the prepared carpet material tooling in the vacated space;

[0076] 3. Use butyl rubber and two-component sound-absorbing cotton to seal the joints of the windows;

[0077] 4. Use an ultrasonic leakage instrument to check the sealing status of the overall sound insulation window area to ensure no leakage;

[0078] 5. Use the sound intensity sensor to test the sound insulation performance, the test resu...

Embodiment 2

[0079] The test window and test method embodiment 2 are as follows:

[0080] Sound insulation performance test of the engine compartment firewall of an SUV model:

[0081] 1. The size of the test engine compartment firewall is 1700mmX950mm;

[0082] The size of the sample is larger than the middle window 1650mmX1350mm, and the large window is used for testing;

[0083] 2. Use the steel chain to connect the large window panel 2 with the pulley mechanism on the wall through the eyebolt 7, and lift and remove the entire large window panel 2;

[0084] Install the prepared engine compartment firewall tooling on the vacated space;

[0085] 3. Use butyl rubber and two-component sound-absorbing cotton to seal the joints of the windows;

[0086] 4. Use an ultrasonic leakage instrument to check the sealing status of the overall sound insulation window area to ensure no leakage;

[0087] 5. Use the sound intensity sensor to test the sound insulation performance, the test results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com