Wet joint connection design of prefabricated concrete beam

A technology of prefabricated concrete and wet joints, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of complex shape of reserved steel bars, difficulty in installation of beams and slabs on site, inconvenient processing and construction, etc., to achieve convenient construction and structure Simple and cost-effective construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in conjunction with accompanying drawing and specific embodiment:

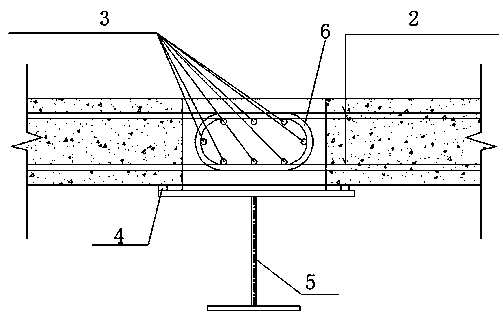

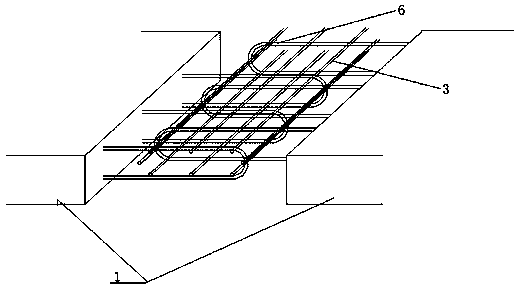

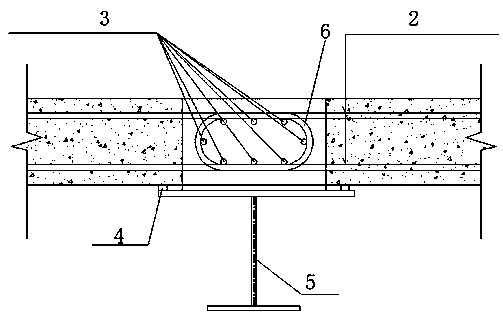

[0021] Such as figure 1 As shown, a wet joint connection design of precast concrete beams, the wet joint is formed by the reserved gap between two adjacent precast concrete beam slabs 1; The corresponding precast concrete beam slabs protrude, and the steel bars at the ends are bent into a semi-circular shape; the semi-circular steel bars 6 reserved for two adjacent precast concrete beam slabs intersect with each other at the wet joints, forming a structure for bearing complex stresses. In the annular area of the core concrete, the semi-annular reserved steel bar of each precast concrete beam slab is used as the U-shaped stirrup of the core concrete, and the opening direction of the U-shaped stirrup corresponds to the setting of the corresponding precast concrete beam slab; two adjacent precast concrete beams The U-shaped stirrups of the concrete beam slab are stagge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com