Method for improving growth efficiency of silicon carbide crystals

A technology of crystal growth and silicon carbide, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of complex cleaning of the upper cover, waste of silicon carbide sources, failure of silicon carbide sources to grow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

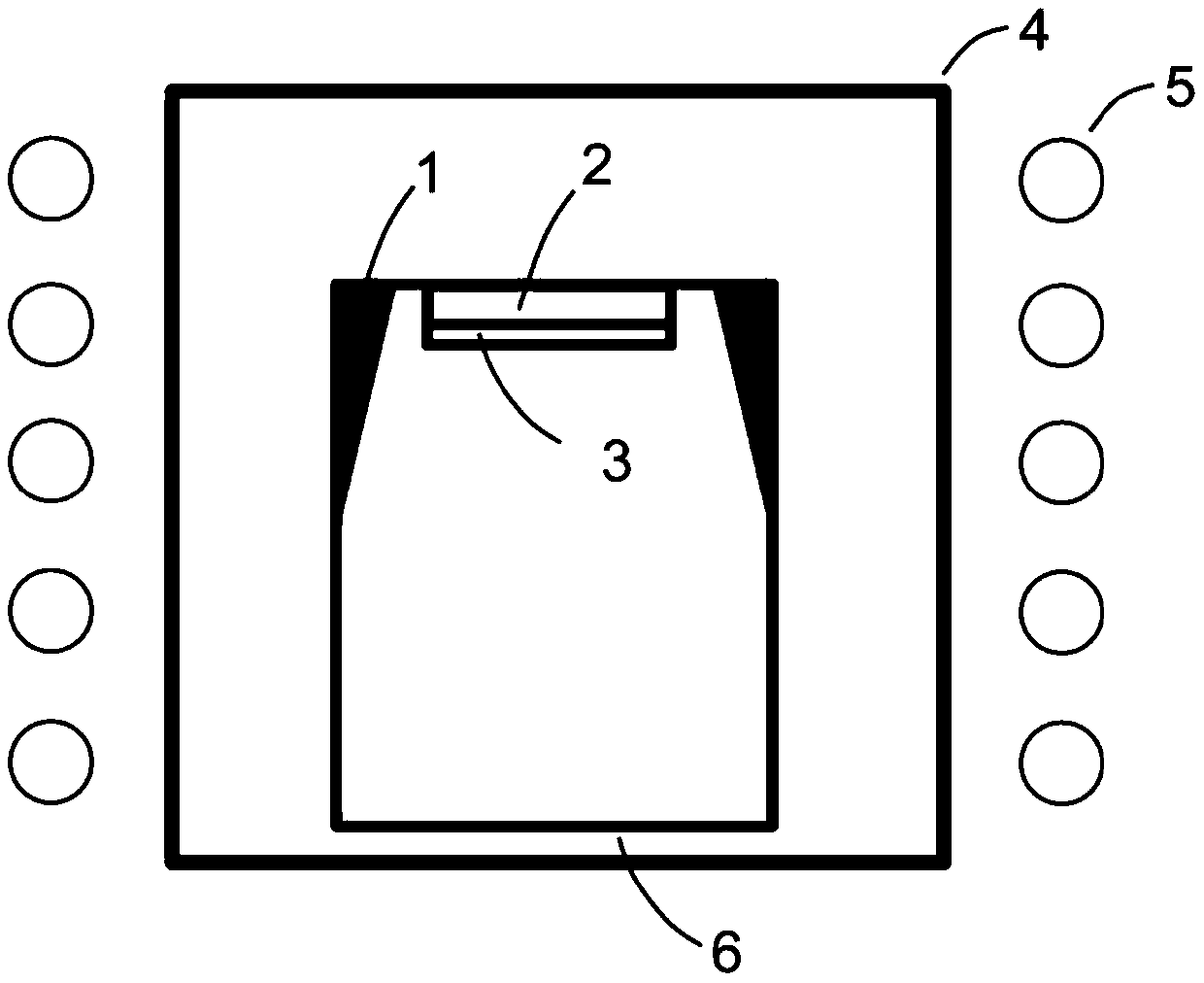

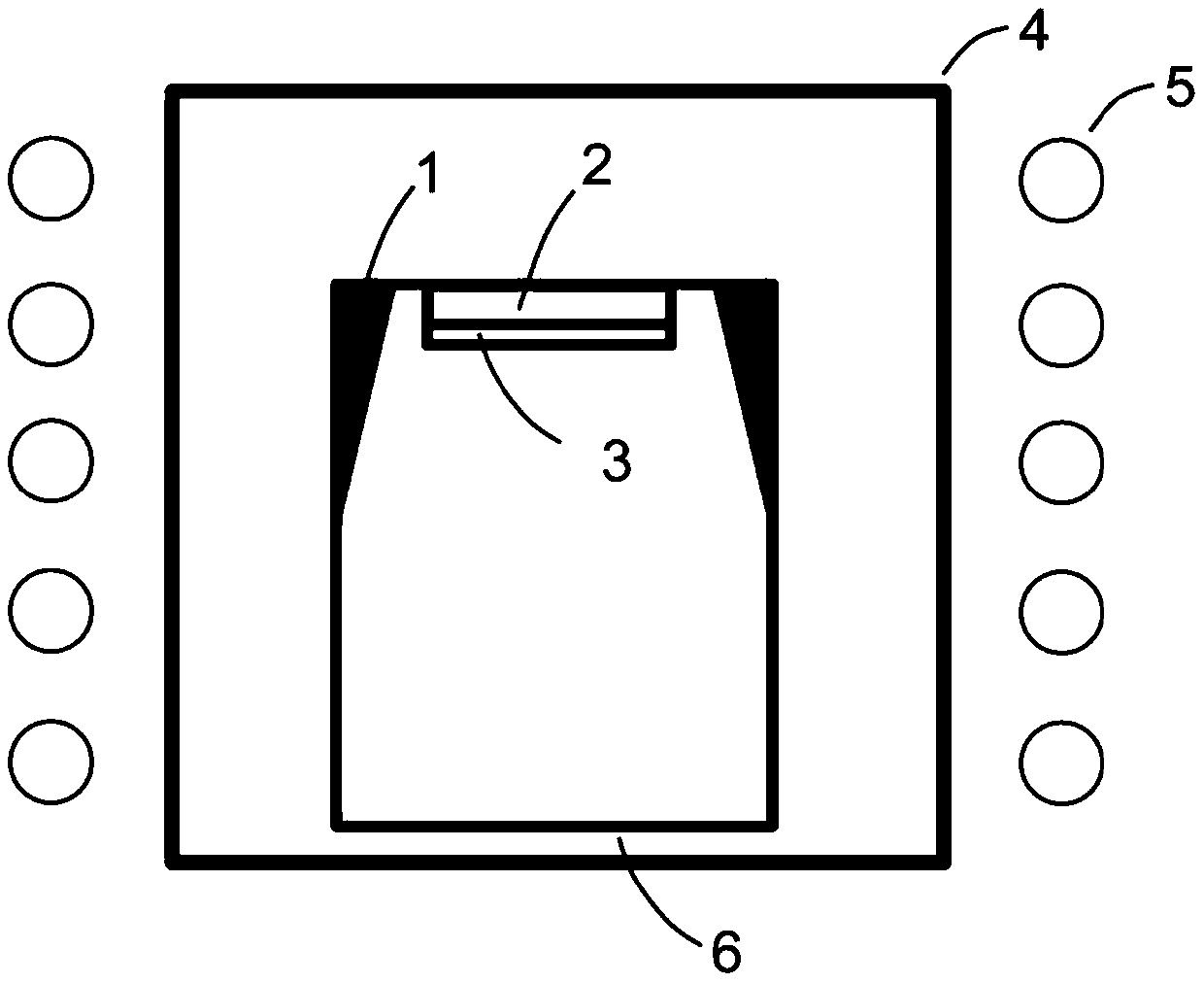

[0008] The inclined chamfer inside the crucible is processed by computer numerical control technology (CNC) to produce a concave inclined surface, and the inclined surface is presented along the inner side of the upper mouth of the crucible in a complete circle. The inclined surface extends toward the bottom of the crucible, so as to achieve a form in which the upper wall of the crucible is thick and the lower wall is thin.

[0009] The angled crucible with concave inclined surface can be concave, flat or convex. The extension length to the bottom of the crucible can be 1 / 8 to 7 / 8 of the height of the crucible. The plane angle is between 10° and 35°. The range of concave and convex surfaces shall not exceed 1 / 8 of the crucible diameter.

[0010] The inclined angle in the crucible can effectively reduce the temperature gradient difference between the seed crystal and the angle, which is 50% to 80% smaller than the traditional physical vapor transport method, reducing the atta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com