High-strength high-elastic-modulus deformed magnesium alloy and preparation method thereof

A deformed magnesium alloy, high elasticity technology, applied in the field of metal material preparation, can solve problems such as difficulty in adapting to large-area industrial applications, cumbersome preparation process, poor deformation ability, etc. The effect of compressive deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

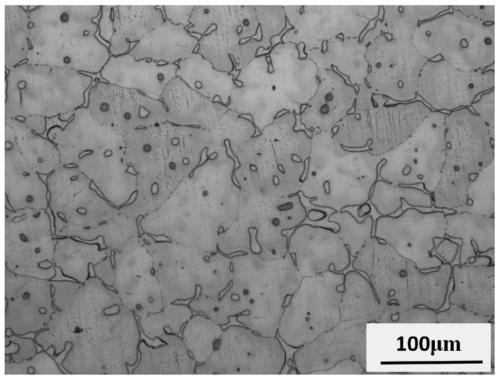

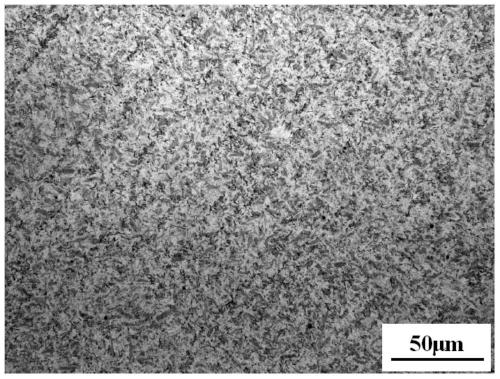

[0063] The alloy composition (mass percentage) is: Zn is 10.0%, Zr is 0.4%, Sr is 0.3%, Sc is 0.1%, and the rest is magnesium and unavoidable impurities.

Embodiment 2

[0065] The alloy composition (mass percentage) is: 8.0% of Zn, 0.3% of Zr, 0.3% of Sr, 0.05% of Sc, and the rest are magnesium and unavoidable impurities.

Embodiment 3

[0067] The alloy composition (mass percentage) is: 13.0% of Zn, 0.5% of Zr, 0.5% of Sr, 0.1% of Sc, and the rest are magnesium and unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com