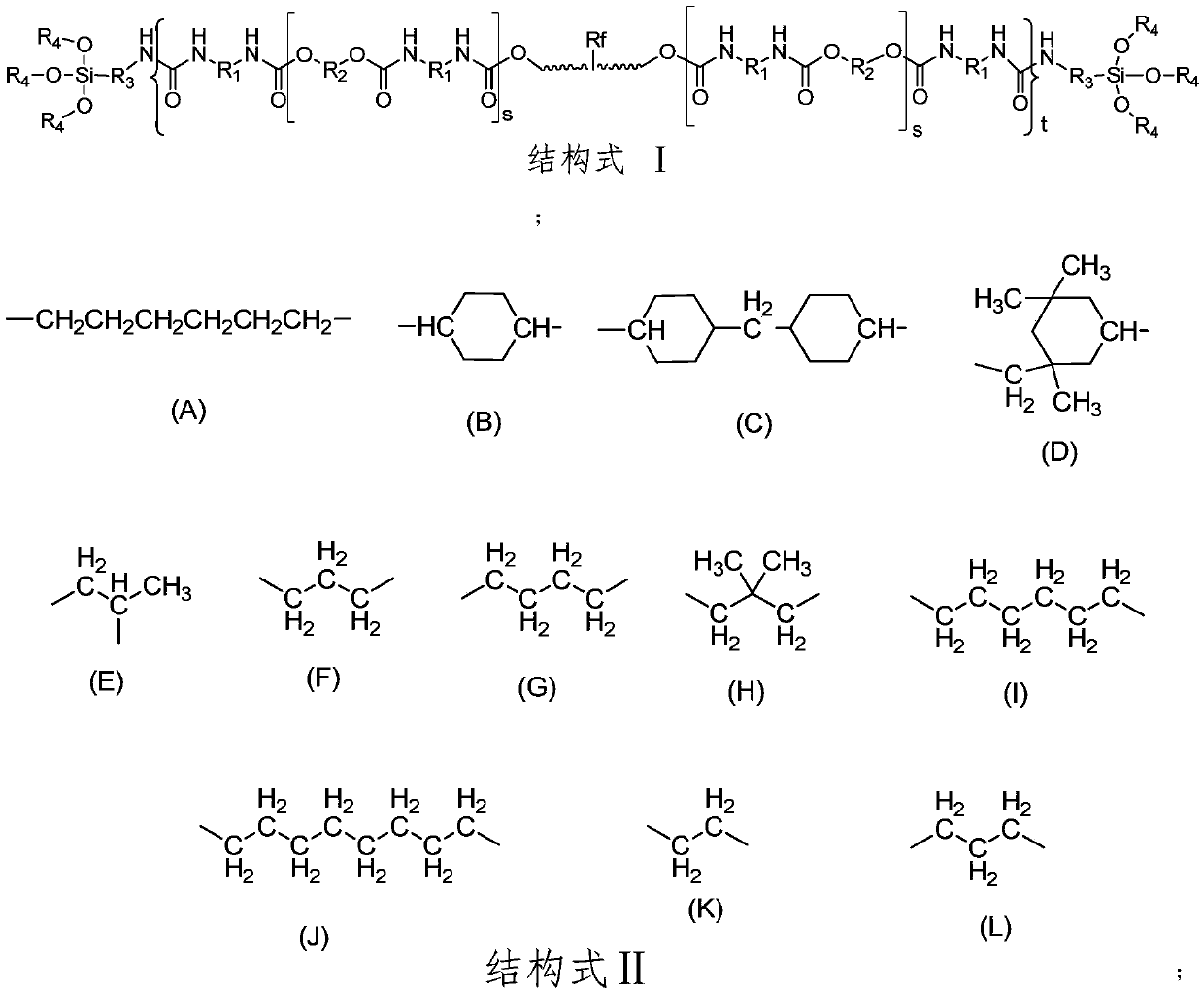

One-component normal-temperature self-crosslinked fluorinated polyurethane coating material and preparation method thereof

A polyurethane coating and self-crosslinking technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of incomplete reaction, high price, environmental hazards, and difficulty in wide application, and achieve stable product performance and good solubility effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

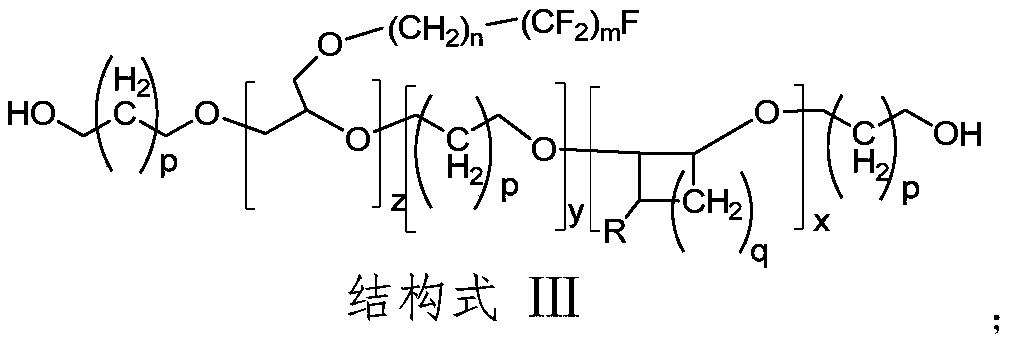

[0031] Preparation of Side Chain Fluorine-Containing Polyether Diol with Structural Formula Ⅲ Containing 6.2% Fluorine

[0032] 0.072 mol of 2-(tridecafluorohexyl) ethyl glycidyl ether and 1.128 mol of n-butyl glycidyl ether were dissolved in 50 mL of dichloromethane to form a dichloromethane mixed solution.

[0033] Then, in a 500mL kettle, after replacing the air in the kettle with pure nitrogen, cool down to 0°C, add 2.4mol tetrahydrofuran, 100mL dichloromethane, 0.072mol boron trifluoride ether and 0.216mol ethylene glycol, cool down to 0°C and stir After 20 minutes and maintaining the temperature, add the above-prepared dichloromethane mixed solution dropwise, and control the dropwise completion within 2 hours. Maintained at 0°C, reacted for 18h. Add 20ml of deionized water to terminate the reaction, distill off the solvent, and neutralize to neutral with sodium carbonate solution. Add 100mL deionized water to wash for 20min, and let stand to separate layers. The oil p...

Embodiment 2

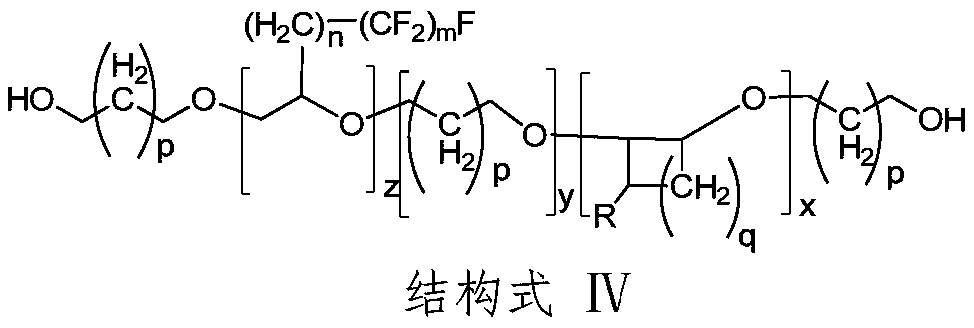

[0038] Preparation of Side Chain Fluorinated Polyether Diol with Structural Formula IV Containing 12.2% Fluorine

[0039] 0.157 mol of 2-(tridetrifluorohexyl) ethyl glycidyl ether and 1.043 mol of n-butyl glycidyl ether were dissolved in 50 mL of dichloromethane to form a dichloromethane mixed solution.

[0040] In a 500mL kettle equipped with a stirrer, after replacing the air in the kettle with pure nitrogen, cool down to 0°C, add 100mL of dichloromethane as a solvent, add 2.4mol of tetrahydrofuran, 0.072mol of boron trifluoride ether and 0.216mol of ethylene dichloride alcohol. The dichloromethane mixed solution prepared above was added dropwise, and the controlled dropwise addition was completed within 5 hours. Keep at 0°C, react for 18 hours, add 60ml of deionized water to terminate the reaction, distill off the solvent, and neutralize to neutral with sodium bicarbonate solution. Add 200mL of deionized water, stir and wash with water for 20min, stand to separate and sep...

Embodiment 3

[0045] Preparation of Side Chain Fluorinated Polyether Diol with Structural Formula Ⅲ Containing 17.9% Fluorine

[0046] 0.255 mol of 2-(tridefluorohexyl) ethyl glycidyl ether and 0.945 mol of butyl glycidyl ether were dissolved in 50 mL of dichloromethane to form a dichloromethane mixed solution.

[0047] In a 500mL kettle equipped with a stirrer, after replacing the air in the kettle with pure nitrogen, cool down to 0°C and add 2.4mol tetrahydrofuran, 0.072mol boron trifluoride ether and 0.216mol 1,2-propanediol. The dichloromethane mixed solution prepared above was added dropwise, and the controlled dropwise addition was completed within 5 hours. Keep at 0°C, react for 18 hours, add 20ml of deionized water to terminate the reaction, distill off the solvent, and neutralize to neutral with sodium bicarbonate solution. Add 250 mL of deionized water, stir and wash with water for 20 min, stand to separate and separate, the oil phase is washed once again with distilled water, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com