High-concentration gasoline detergent and preparation process thereof

A gasoline detergent and a technology for preparation process, which are applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as unfavorable popularization, increase in colloid, increase in carbon deposition, etc., and achieve production cost saving and strong dissolving ability. , the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

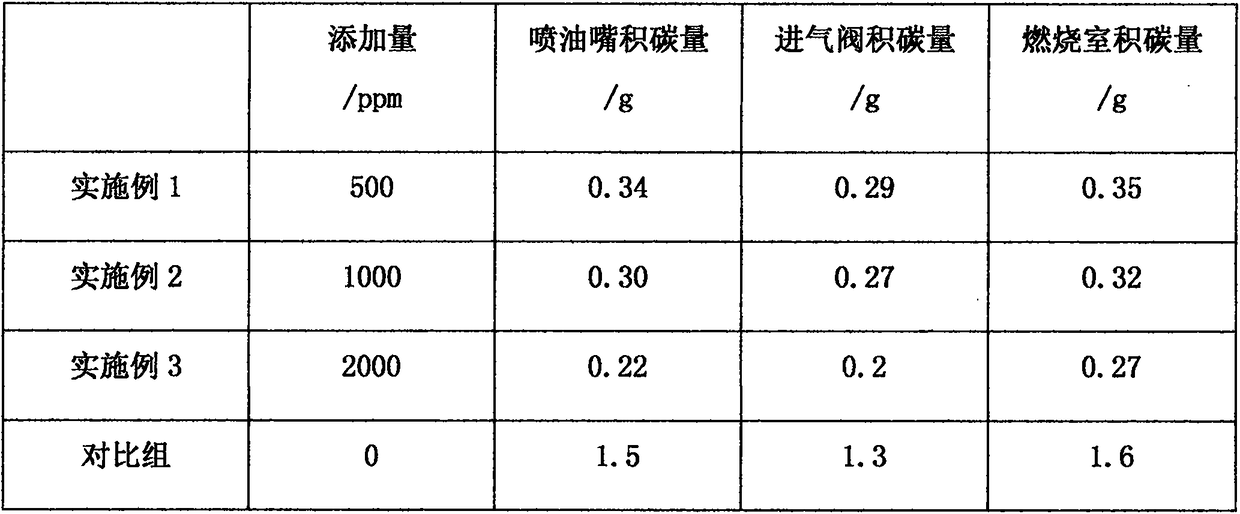

Embodiment 1

[0026] A highly concentrated gasoline detergent, the formula includes: polyether amine, polyisobutylene amine, di-tert-butyl p-cresol, disalicylidene propylene diamine, benzotriazole, xylene, aviation kerosene, n-butyl Alcohol, isopropanol and SP demulsifier, the mass percentages of each component are: 20% polyether amine, 30% polyisobutylene amine, 0.8% di-tert-butyl p-cresol, 0.75% diethylene glycol Salicylpropylenediamine, 0.75% benzotriazole, 5% xylene, 20% aviation kerosene, 5.7% n-butanol, 5% isooctyl alcohol and 2% SP demulsifier.

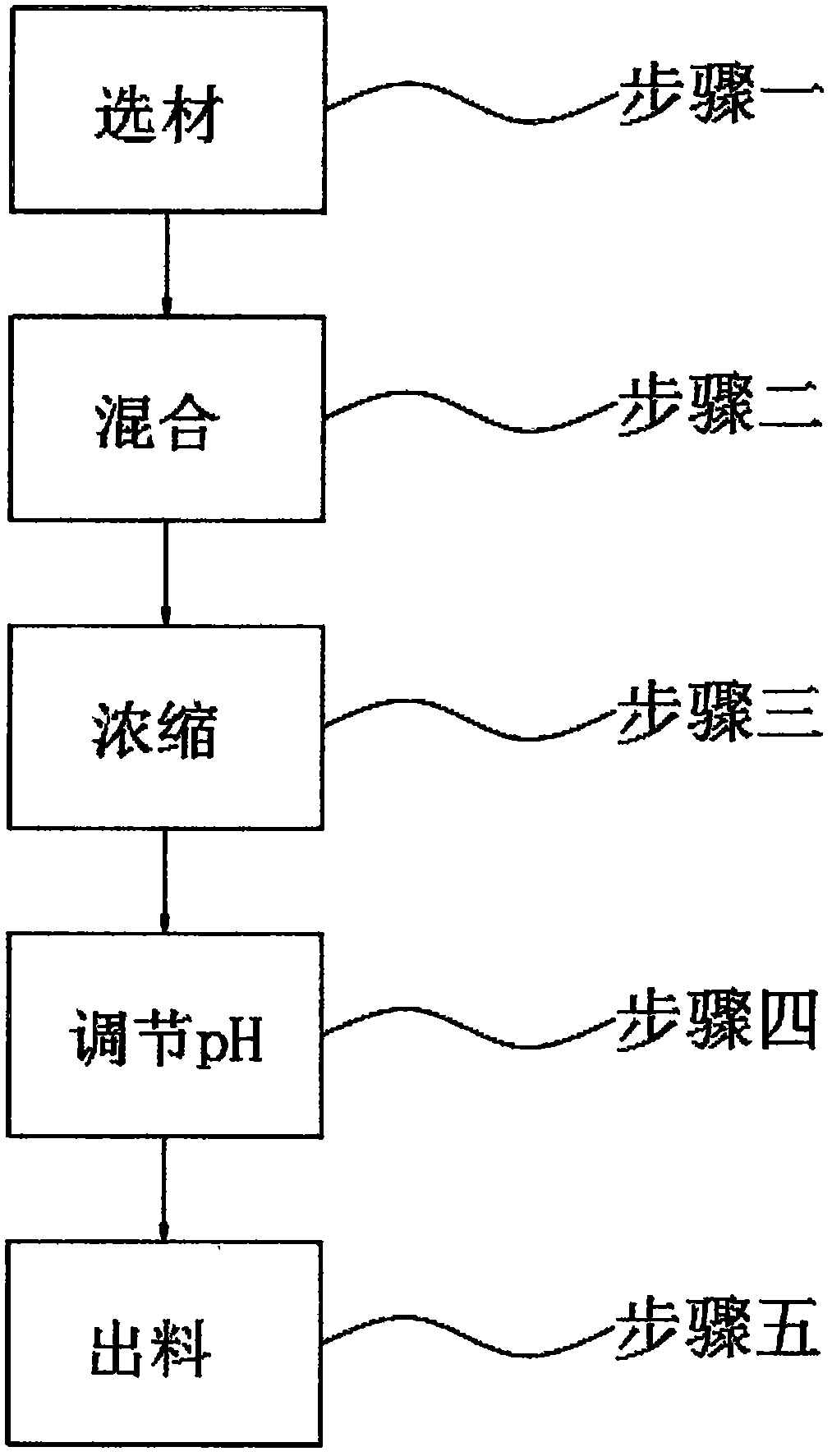

[0027] A preparation process of a highly concentrated gasoline detergent, comprising the following steps: Step 1, material selection; Step 2, mixing; Step 3, concentrating; Step 4, adjusting pH; Step 5, discharging;

[0028] Wherein in the above-mentioned step 1, according to the mass percentage content of each component is respectively: 20% polyether amine, 30% polyisobutene amine, 0.8% di-tert-butyl p-cresol, 0.75% disalicylidene Propylen...

Embodiment 2

[0038] A highly concentrated gasoline detergent, the formula includes: polyether amine, polyisobutylene amine, di-tert-butyl p-cresol, disalicylidene propylene diamine, benzotriazole, xylene, aviation kerosene, n-butyl Alcohol, isopropanol and SP demulsifier, the mass percentages of each component are: 15% polyether amine, 35% polyisobutylene amine, 0.8% di-tert-butyl p-cresol, 0.75% diethylene glycol Salicylpropylenediamine, 0.75% benzotriazole, 5% xylene, 20% aviation kerosene, 5.7% n-butanol, 5% isooctyl alcohol and 2% SP demulsifier.

[0039] A preparation process of a highly concentrated gasoline detergent, comprising the following steps: Step 1, material selection; Step 2, mixing; Step 3, concentrating; Step 4, adjusting pH; Step 5, discharging;

[0040] Wherein in the above-mentioned step 1, according to the mass percentage of each component, it is respectively: 15% polyether amine, 35% polyisobutylene amine, 0.8% di-tert-butyl p-cresol, 0.75% disalicylidene Propylened...

Embodiment 3

[0050] A highly concentrated gasoline detergent, the formula includes: polyether amine, polyisobutylene amine, di-tert-butyl p-cresol, disalicylidene propylene diamine, benzotriazole, xylene, aviation kerosene, n-butyl Alcohol, isopropanol and SP demulsifier, the mass percentages of each component are: 25% polyether amine, 25% polyisobutylene amine, 0.8% di-tert-butyl p-cresol, 0.75% diethylene glycol Salicylpropylenediamine, 0.75% benzotriazole, 5% xylene, 20% aviation kerosene, 5.7% n-butanol, 5% isooctyl alcohol and 2% SP demulsifier.

[0051] A preparation process of a highly concentrated gasoline detergent, comprising the following steps: Step 1, material selection; Step 2, mixing; Step 3, concentrating; Step 4, adjusting pH; Step 5, discharging;

[0052] Wherein in the above-mentioned step 1, according to the mass percentage content of each component, it is respectively: 25% polyether amine, 25% polyisobutylene amine, 0.8% di-tert-butyl p-cresol, 0.75% disalicylidene Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com