Continuous synthesis method of glycine methyl ester hydrochloride

A synthesis method, glycine ester technology, applied in organic chemistry methods, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as unfavorable energy saving and consumption reduction, low equipment utilization rate, unstable quality, etc., to improve equipment utilization The effect of improving the utilization rate, improving the utilization rate and stabilizing the product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

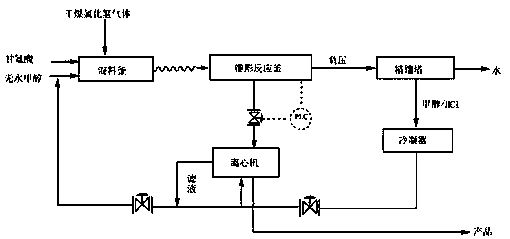

Image

Examples

Embodiment 1

[0022] At room temperature, mix 75kg glycine and 320kg anhydrous methanol (n 甘氨酸 :n 甲醇 =1:10) into a glass-lined mixing tank with a volume of 500L, and under stirring conditions, feed hydrogen chloride gas at a flow rate of 20m³ / h until glycine is completely dissolved (the hydrogen chloride gas feeding time is about 25min) and control the temperature in the mixing tank <40°C; keep the system at the reaction temperature of 55~60°C, continuously pour the uniformly mixed materials into the conical reactor, add 1.68kg of glycine methyl ester hydrochloride crystals when the materials are continuously injected into the reactor for about 15 minutes, Insulate the reaction and control the stirring rate of 180r / min, and the continuously precipitated crystals are deposited in the conical storage tank at the bottom of the reactor;

[0023] While continuously feeding the reaction, the reactor establishes a negative pressure system of about 0.034MPa, and the water generated by the reaction...

Embodiment 2

[0027] At room temperature, mix 75kg glycine and 256kg anhydrous methanol (n 甘氨酸 :n 甲醇 =1:8) Put it into a glass-lined mixing tank with a volume of 500L, feed hydrogen chloride gas at a flow rate of 30m³ / h under stirring conditions until glycine is completely dissolved (the hydrogen chloride gas feeding time is about 20min) and control the temperature in the mixing tank <40°C; keep the system at the reaction temperature of 55~60°C, continuously pour the uniformly mixed materials into the conical reactor, add 1.68kg of glycine methyl ester hydrochloride crystals when the materials are continuously injected into the reactor for about 15 minutes, Insulate the reaction and control the stirring rate of 240r / min, and the continuously precipitated crystals are deposited in the conical storage tank at the bottom of the reactor;

[0028] While continuously feeding the reaction, a negative pressure system of about 0.025MPa is established in the reactor, and the water generated by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com