Nitrogen-doped porous carbon-supported bimetallic catalyst and preparation method and application thereof

A technology of nitrogen-doped porous carbon and bimetallic catalysts, which is applied in catalyst activation/preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc. It can solve the problems of low efficiency, unfavorable catalyst synthesis, cumbersome steps, etc., and achieves broad application prospects , excellent catalytic activity, simple separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0037] Preparation Example 1: One-pot synthesis of nitrogen-doped porous carbon material-supported Ru-W catalyst (Ru-W / NC-800)

[0038] 1 kg of cleaned bamboo shoots was cut into pieces, dried, and the solids obtained were ground into powders. Take 2g powder, mix with 18mL deionized water, 0.28mL RuCl 3 Mix the solution (5wt%), add 0.0972g ammonium metatungstate (AMT), mix the above mixture evenly, transfer it to a hydrothermal kettle, react at 180°C for 6h, filter, wash, and dry to obtain a brown solid. Then put the obtained solid in a tube furnace and bake it to 800°C under a nitrogen atmosphere, and keep it warm for 1 hour to obtain a nitrogen-doped porous carbon-supported catalyst, represented by Ru-W / NC-800.

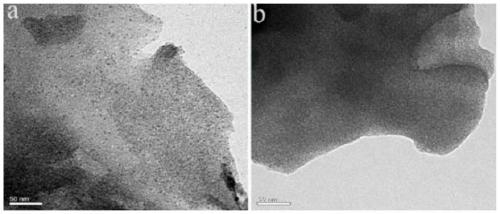

[0039] figure 1 It is the TEM image of the Ru-W catalyst supported by nitrogen-doped porous carbon prepared according to the present example, such as figure 1 As shown, the Ru nanoparticles in the material are uniformly dispersed on the surface of the carbon mate...

preparation Embodiment 4

preparation Embodiment 2

[0040] Preparation Example 2: Preparation of Multi-step Synthesis of Nitrogen-doped Porous Carbon Material Supported Ru-W Catalyst (HRu-W / NC)

[0041] Take 2g of bamboo powder, mix evenly with 18mL of deionized water, transfer to a hydrothermal kettle, react at 180°C for 6h, filter, wash, and dry to obtain a brown solid hydrothermal carbon.

[0042] Take 1g of hydrothermal carbon, mix with 4mL deionized water, 0.28mL RuCl 3 The solution (5wt%) was mixed with 0.0972g AMT, and stood at 25°C for 3h. Dry at 50°C for 12h, grind the above mixture and put it in a tube furnace for roasting under nitrogen atmosphere, keep it at 800°C for 1 hour. After the tube furnace dropped to room temperature, the sample was taken out to obtain a nitrogen-doped porous carbon-supported catalyst synthesized by a multi-step method, represented by HRu-W / NC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com